Troubleshooting

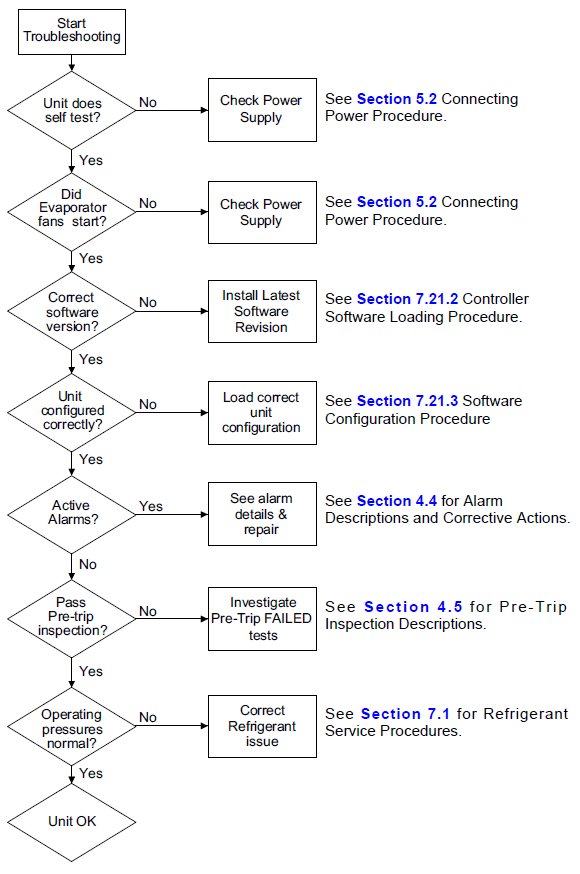

Figure 6.1 Unit Troubleshooting Sequence

Table 6–1 Troubleshooting Symptoms

|

Condition |

Possible Cause |

Remedy / Reference |

|---|---|---|

|

No power to unit |

External power source OFF |

Turn on |

|

Start-Stop switch (ST) OFF or defective |

Check |

|

|

Circuit breaker tripped or OFF |

Check |

|

|

Autotransformer not connected |

||

|

Loss of control power |

Circuit breaker OFF or defective |

Check |

|

Control transformer defective |

Replace |

|

|

Fuse (F3 / F4) blown |

Check |

|

|

Start-Stop switch (ST) OFF or defective |

Check |

|

|

AC Line Filter fails or is defective |

||

|

Component(s) not operating |

Evaporator fan motor internal protector open |

|

|

Condenser fan motor internal protector open |

||

|

Compressor internal protector open |

||

|

High Pressure Switch (HPS) open |

||

|

Heat Termination Thermostat (HTT) open |

Replace |

|

|

Current sensor malfunction |

Replace |

|

|

Compressor hums, but does not start |

Line voltage is low |

Check |

|

Single phasing |

Check |

|

|

Motor windings shorted or grounded |

||

|

Compressor seized |

||

|

Container |

Hot load |

Normal |

|

Box insulation defective or air leak |

Repair |

|

|

Refrigeration system |

Refrigerant shortage |

|

|

Evaporator coil covered with ice |

||

|

Evaporator coil plugged with debris |

||

|

Evaporator fan(s) rotating backwards |

||

|

Air bypass around evaporator coil |

Check |

|

|

Controller set too low |

Reset |

|

|

Compressor service valves or liquid line shutoff valve partially closed |

Open valves completely |

|

|

Condenser dirty |

||

|

Compressor worn |

||

|

Current limit (Cd32) set to wrong value |

Cd32 |

|

|

Economizer Solenoid Valve (ESV) malfunction |

||

|

Digital Unloader Valve (DUV) stuck open |

Replace |

|

|

Electronic Expansion Valve (EEV) |

Replace |

|

|

Refrigeration system |

Abnormal pressures |

|

|

Abnormal temperatures |

||

|

Abnormal currents |

||

|

Controller malfunction |

||

|

Evaporator fan or motor defective |

||

|

Compressor service valves or liquid line shutoff valve partially closed |

Open valves completely |

|

|

Frost on coil |

||

|

Digital Unloader Valve (DUV) stuck open |

Replace |

|

|

Electronic Expansion Valve (EEV) |

Replace |

|

|

No operation of any kind |

Start-Stop switch (ST) OFF or defective |

Check |

|

Circuit breaker OFF or defective |

Check |

|

|

External power source OFF |

Turn ON |

|

|

No control power |

Circuit breaker or fuse defective |

Replace |

|

Control Transformer defective |

Replace |

|

|

Evaporator fan internal motor protector open |

||

|

Heat relay defective |

Check |

|

|

Heater termination thermostat open |

||

|

Unit will not heat or has insufficient heat |

Heater(s) defective |

|

|

Heater contactor or coil defective |

Replace |

|

|

Evaporator fan motor(s) defective or rotating backwards |

||

|

Evaporator fan motor contactor defective |

Replace |

|

|

Controller malfunction |

||

|

Wiring defective |

Replace |

|

|

Terminal connections loose |

Tighten |

|

|

Line voltage is low |

||

|

Unit fails to stop heating |

Controller improperly set |

Reset |

|

Controller malfunction |

||

|

Heater Termination Thermostat (HTT) remains closed along with the heat relay |

||

|

Defrost timer malfunction (Cd27) |

Cd27 |

|

|

Terminal connections loose |

Tighten |

|

|

Wiring defective |

Replace |

|

|

Defrost Temperature Sensor (DTS) defective or Heat Termination Thermostat (HTT) open |

Replace |

|

|

Heater contactor or coil defective |

Replace |

|

|

Will not initiate defrost manually |

Manual defrost switch defective |

Replace |

|

Keypad defective |

Replace |

|

|

Defrost Temperature Sensor (DTS) open |

Replace |

|

|

Initiates but relay (DR) drops out |

Line voltage is low |

|

|

Initiates but does not defrost |

Heater contactor or coil defective |

Replace |

|

Heater(s) burned out |

||

|

Frequent defrost |

Load is wet |

Normal |

|

Condenser coil dirty |

||

|

Condenser fan rotating backwards |

||

|

Condenser fan inoperative |

||

|

Refrigerant overcharge or non-condensables |

||

|

Discharge service valve partially closed |

Open |

|

|

Electronic Expansion Valve (EEV) control malfunction |

Replace |

|

|

Low suction pressure |

Software and/or controller configuration incorrect |

Check |

|

Suction Pressure Transducer (SPT) or Evaporator Pressure Transducer (EPT) failed |

Replace |

|

|

Suction service valve partially closed |

Open |

|

|

Filter drier partially plugged |

||

|

Refrigerant charge low |

||

|

Evaporator air flow not existent or air flow restricted |

||

|

Frost on evaporator coil excessive |

||

|

Evaporator fan(s) rotating backwards |

||

|

Electronic Expansion Valve (EEV) control malfunction |

Replace |

|

|

Digital Unloader Valve (DUV) failed |

Replace |

|

|

Suction and discharge pressures tend to equalize when unit is operating |

Compressor operating in reverse |

|

|

Compressor cycling / stopped |

Check |

|

|

Digital Unloader Valve (DUV) failed |

Replace |

|

|

Compressor |

Compressor start up after an extended shutdown |

Normal |

|

Brief chattering when manually shut down |

||

|

Compressor operating in reverse |

||

|

Mounting bolts loose or resilient mounts worn |

Tighten / Replace |

|

|

Upper mounting loose |

||

|

Slugging loose |

||

|

Condenser or Evaporator Fan |

Bent, loose or striking venturi |

Check |

|

Motor bearings worn |

||

|

Motor shaft bent |

||

|

Software and/or controller configuration incorrect |

Check |

|

|

Sensor defective |

||

|

Wiring defective |

Check |

|

|

Refrigerant charge low |

||

|

Coil has frost build-up |

||

|

Coil dirty |

||

|

No or partial evaporator air flow |

Evaporator fan motor internal protector open |

|

|

Evaporator fan motor(s) defective |

||

|

Evaporator fan(s) loose or defective |

||

|

Evaporator fan contactor defective |

Replace |

|

|

Low suction pressure |

Software and/or controller configuration incorrect |

Check |

|

Suction Pressure Transducer (SPT) or Evaporator Pressure Transducer (EPT) failed |

Replace |

|

|

Suction Service Valve partially closed |

Open |

|

|

Filter drier partially plugged |

||

|

Refrigerant charge low |

||

|

Evaporator air flow not existent or air flow restricted |

||

|

Evaporator coil excessive frost build-up |

||

|

Evaporator fan(s) rotating backwards |

||

|

Electronic Expansion Valve (EEV) control malfunction |

||

|

Digital Unloader Valve (DUV) failed |

Replace |

|

|

Sensor loose or insufficiently clamped |

Replace |

|

|

High suction pressure with low superheat |

Valve contains foreign material |

|

|

Suction Pressure Transducer (SPT) or Evaporator Pressure Transducer (EPT) failed |

Replace |

|

|

Electronic Expansion Valve (EEV) control malfunction |

||

|

Powerhead improperly seated |

Ensure powerhead is locked and in place |

|

|

Liquid slugging in compressor |

Suction Pressure Transducer (SPT) or Evaporator Pressure Transducer (EPT) failed |

Replace |

|

Electronic Expansion Valve (EEV) failed |

||

|

Unit will not start |

Circuit breaker (CB1 or CB2) tripped |

Check |

|

Autotransformer defective |

||

|

Power source not turned ON |

Check |

|

|

460 VAC power plug not inserted into the receptacle |

||

|

High discharge pressure |

Coil dirty |

|

|

Non-condensables |

||

|

Condenser fan starts and stops |

Water pressure switch malfunction |

Check |

|

Water supply interruption |

Check |

|

|

6.14Compressor Operating in Reverse NOTE: The compressor may start in reverse for up to 10 seconds to determine correct phase rotation if required for phase detection. |

||

|

Allowing the scroll compressor to operate in reverse for more than two minutes will result in internal compressor damage. Turn the start- stop switch OFF immediately. |

||

|

Electrical |

Compressor incorrectly wired |

Check |

|

Compressor contactor(s) incorrectly wired |

||

|

Current sensor incorrectly wired |

||

|

Condenser coil dirty |

||

|

Condenser fan rotating backwards |

||

|

Condenser fan inoperative |

||

|

Refrigerant overcharge or non-condensibles |

||

|

Discharge service valve partially closed |

Open |

|

|

Electronic Expansion Valve (EEV) control malfunction |

Replace |

|

|

Suction Pressure Transducer (SPT) or Evaporator Pressure Transducer (EPT) failed |

Replace |

|

|

Discharge temperature sensor drifting high |

Replace |

|

|

Economizer Expansion Valve (EEV), Economizer coil, or Economizer Solenoid Valve failed |

Replace |

|

|

Economizer Expansion Valve (EEV), Economizer coil, or Economizer Solenoid Valve plugged |

Replace |

|

|

Sensor loose or insufficiently clamped |

Replace |

|

|

Current sensor wiring |

Check |

|