Introduction

The Carrier Transicold PrimeLINE units are of lightweight aluminum frame construction, designed to be bolted onto the container front to serve as the container’s front wall. Forklift pockets are provided for installation and removal.

PrimeLINE units are self-contained, all electric units, which include cooling and heating systems to provide precise temperature control. The units are supplied with a complete charge of refrigerant and compressor lubricating oil, and are ready for operation upon installation.

The base unit operates on nominal 380/460 volt, 3-phase, 50/60 hertz (Hz) power. An optional autotransformer may be fitted to allow operation on nominal 190/230, 3-phase, 50/60 Hz power. Control system power is provided by a transformer which steps the supply power down to 18 and 24 volts, single phase.

PrimeLINE unit models covered in this manual are:

•PrimeLINE standard units, models 69NT40-571-1xx

•PrimeLINE EDGE units, models 69NT40-571-3xx

These units, as shown in Figure 2.1, will appear identical with the exception of labels. The PrimeLINE EDGE unit may have an EDGE label in the center. The other way to determine the type of unit is to refer to the model number listed on the unit nameplate, which is shown in Section 2.3.

Figure 2.1 PrimeLINE Unit - Standard (left) vs EDGE (right)

PrimeLINE unit models 69NT40-571-1xx and 571-3xx are R-513A-ready units. They are supplied with a complete charge of R-134a refrigerant. But, they are capable of being field converted to R-513A refrigerant at a later date as requested by the unit owner. All information in this manual pertaining to R-513A is only applicable to units that have either been converted or are being converted to R-513A.

The refrigerant charge amount is listed on the unit nameplate, as shown in Section 2.3.

2.3Configuration Identification

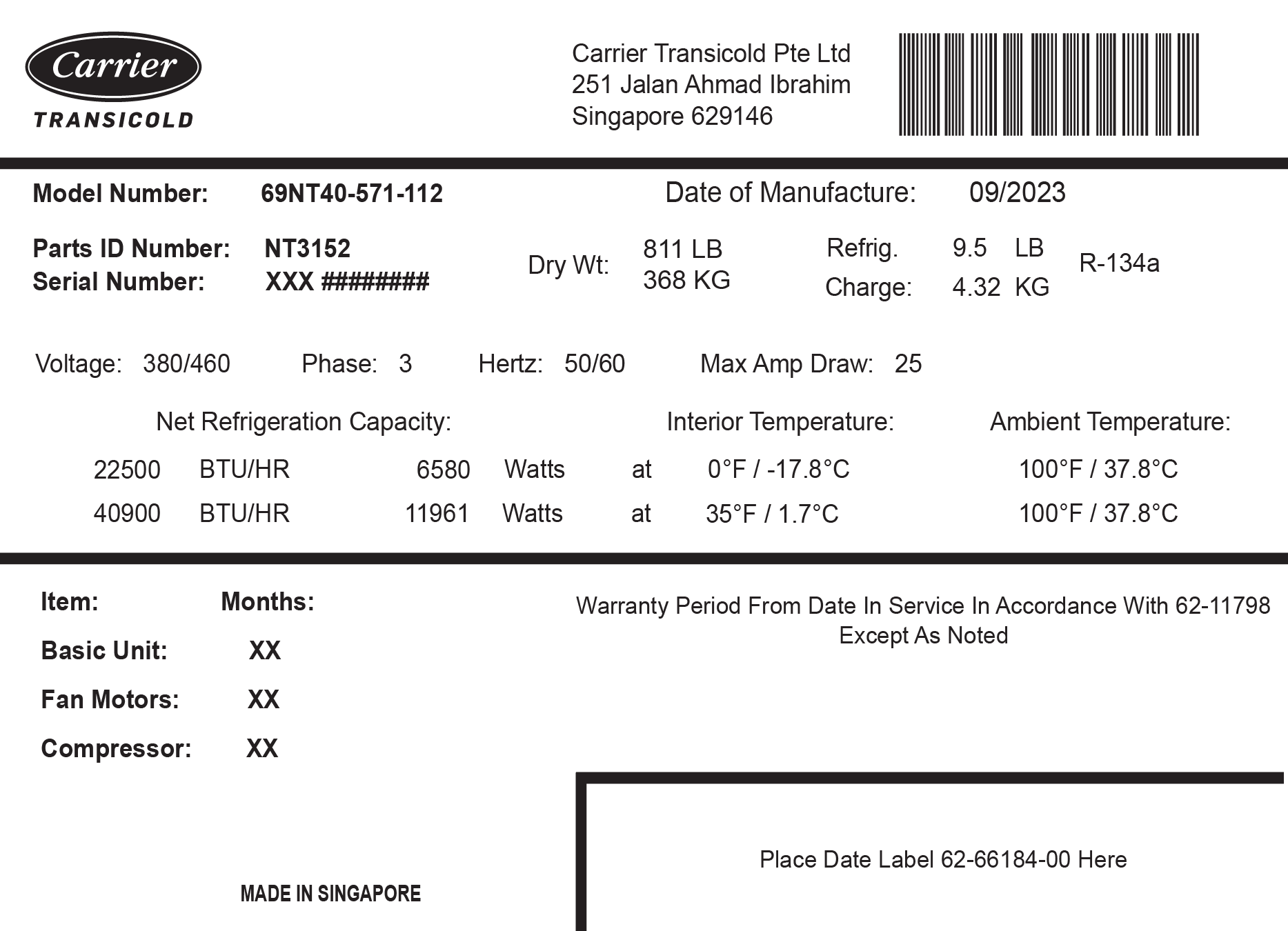

Unit identification information is provided on a nameplate, as shown in Figure 2.2, located under the condenser fan near the power cable storage area. The plate provides helpful unit information including: date of manufacture, refrigerant charge, unit model number, and unit parts identification number (PID). The model number and PID number are helpful for a technician to determine specific configurations and spare parts applicable to that unit.

Figure 2.2 Unit Nameplate

Units are equipped with an aluminum control box, and may be fitted with a lockable door.

2.4.2Controller, Keypad, Display

The controller is a Carrier Transicold Micro-Link 5 microprocessor that automatically selects cooling, holding or heating as required to maintain the desired set point temperature within very close limits. See Section 4.1 for more information. Controllers will be factory-equipped with the latest version of operational software, but will NOT be configured for a specific model number and will need to be configured at the time of installation or sale.

The controller has a keypad and display for viewing or changing operating parameters. The display is also equipped with lights to indicate various modes of operation.

Two replacement controllers are available:

1.Re-manufactured - Controller is equivalent of a new OEM controller, supplied with a 12-month warranty.

2.Repaired - Controller has had previous faults repaired and is upgraded with the latest software.

NOTE: Repaired controllers are NOT to be used for warranty repairs; only full OEM Re-manufactured controllers are to be used.

The unit is fitted with suction and discharge refrigerant temperature sensors. The sensor readings may be viewed on the controller display.

The unit is fitted with evaporator, suction, and discharge pressure transducers. The transducer readings may be viewed on the controller display.

The unit is fitted with a R-513A-ready scroll compressor equipped with suction and discharge service connections. To identify an R-513A-ready compressor in the field, a green dot is located on the top of the compressor on the DUV fitting.

The unit is fitted with a micro channel heat exchanger condenser coil.

The unit is equipped with a three phase condenser fan motor. Opening of the condenser fan motor internal protector will stop the fan motor and the controller will subsequently shut down the compressor. The condenser fan grille is direct bolted.

PrimeLINE units model number 571-1xx have a single speed motor, while PrimeLINE EDGE units model number 571-3xx have a dual speed motor.

The evaporator section is equipped with an evaporator coil and electronic expansion valve (EEV).

The unit is equipped with 2 three-phase, dual speed evaporator fan motors. Opening of an evaporator fan internal protector will shut down the unit.

Each unit is equipped with a tethered set of wiring schematics and wiring diagram plates. The plate sets are ordered using a seven-digit base part number and a two-digit dash number.

Various options may be factory or field equipped to the base unit. These options are described in the following sub-paragraphs.

The refrigeration controller may be fitted with standard replaceable batteries or a rechargeable battery pack. Carrier-provided rechargeable batteries can be recharged via the ML5 controller and allow for wireless communication in battery mode. A non-carrier rechargeable 3-wire battery would charge but the controller will not monitor anything related to it. A standard 2-wire NiCAD battery would not charge.

NOTE: If ambient temperature is greater than 45 deg C, the carrier-provided rechargeable batteries will not charge.

The unit may be fitted with a humidity sensor. This sensor allows setting of a humidity set point in the controller. In dehumidification mode, the controller will operate to reduce internal container moisture level.

The unit may be supplied with fittings for additional temperature probes, which allow recording of USDA Cold Treatment data by the integral DataCORDER function of the Micro-Link refrigeration controller. There is one external calibration receptacle for connection of equipment for calibration. It is located inside the unit along side the USDA receptacles. It is used for USDA probe calibration. There are no write commands capable from this port.

An autotransformer may be provided to allow operation on 190/230, 3-phase, 50/60 Hz power. The autotransformer raises the supply voltage to the nominal 380/460 volt power required by the base unit. The autotransformer may also be fitted with an individual circuit breaker for the 230 volt power.

The unit may be equipped with handles to facilitate access to stacked containers. These fixed handles are located on either side of the unit.

The refrigeration system may be provisioned for a water-cooled condenser. The condenser is constructed using copper nickel tube for sea water applications.

Aluminum back panels may have access doors and/or hinge mounting.

Various power cable and plug designs are available for the main 460 volt supply. The plug options tailor the cables to each customer’s requirements.

Units equipped with an autotransformer require an additional power cable for connection to the 230 volt source. Various power cable and plug designs are available. The plug options tailor the cables to each customer’s requirements.

Various designs are available for storage of the power cables. These options are variations of the compressor section cable guard.

The unit may be fitted with an upper fresh air makeup assembly. The fresh air makeup assembly is available with a Vent Positioning Sensor (VPS) and may also be fitted with screens.

Safety Instruction and Function Code listing labels differ depending on the options installed. Labels available with additional languages are listed in the parts list.

Condenser grilles are direct bolted.

EverFRESH® is a controlled atmosphere option that is able control container atmosphere by supplying nitrogen and oxygen into the container space and simultaneously controlling levels of oxygen and carbon dioxide. This extends the produce ripening process, which increases shelf life and enables longer cargo routes for certain perishable commodities. See Section 5.9.7 for more detail.

Detailed procedures and technical information related to the EverFRESH controlled atmosphere system can be found in the T-374 EverFRESH Manual, located in the Literature section of the Container Refrigeration website. To find the manual from the Literature section, click on Options > EverFRESH.

QUEST (Quality and Energy Efficiency in Storage and Transport) power saving mode helps shipping lines lower their operating costs by decreasing the system’s run time, energy usage and emissions. Quest is a method of temperature control used during steady-state perishable cooling that cycles the compressor on and off according to supply / return air temperature conditions. See Section 5.9.1 for more detail.

TripWise™ is a new premium option available for PrimeLINE units. TripWise is software logic that runs in the background during every voyage and will let you know whenever a standard pre-trip inspection (PTI) is needed. See Section 5.9.3 for more detail.

FuelWise™ is a power-saving option available for PrimeLINE units. FuelWise software works by dynamically cycling the refrigeration system on and off to save energy while still maintaining temperature within +/- 0.25 degrees Celsius of setpoint on an hourly average. See Section 5.9.2 for more detail.