Section 4

4.1Temperature Control Microprocessor System

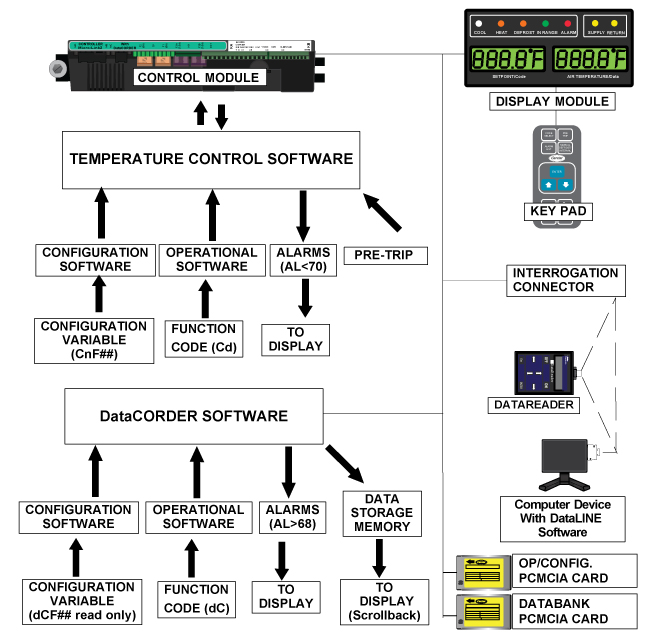

The temperature control Micro-Link 3 microprocessor system (see Figure 4.1) consists of a keypad, display module, the control module (controller) and interconnecting wiring. The controller houses the temperature control software and the DataCORDER software. The temperature control software functions to operate the unit components as required to provide the desired car go temperature and humidity. The DataCORDER soft ware functions to record unit operating parameters and cargo temperature parameters for future retrieval. Cover age of the temperature control software begins with Section 4.2. Coverage of the DataCORDER software is provided in Section 4.7.

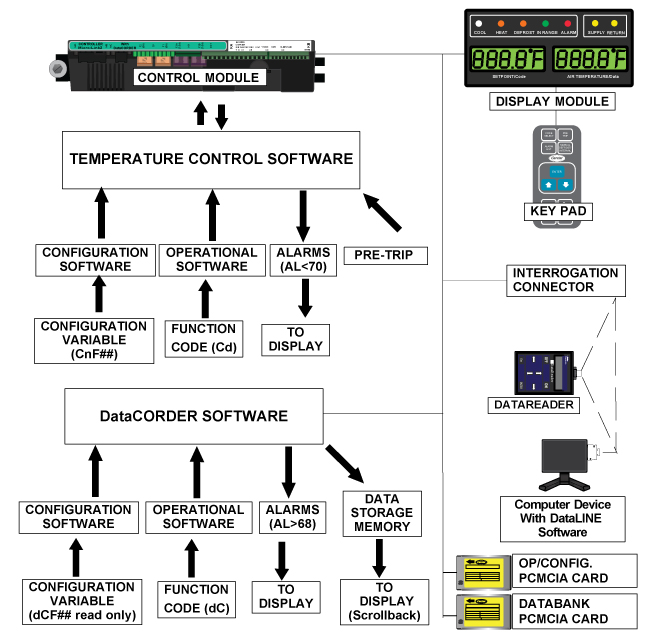

The keypad and display module serve to provide user access and readouts for both of the controller functions, temperature control and DataCORDER. The functions are accessed by keypad selections and viewed on the display module. The components are designed to permit ease of installation and removal.

Figure 4.1 Temperature Control System

Key |

Function |

|---|---|

CODE SELECT |

Accesses function codes. |

PRE TRIP |

Displays Pre-trip selection menu. Discontinues Pre-trip in progress. |

ALARM LIST |

Displays alarm list and clears the alarm queue. |

MANUAL DEFROST / INTERVAL |

Displays selected defrost mode. Depress and hold the MANUAL DEFROST / INTERVAL key for five (5) seconds to initiate defrost using the same logic as if the optional manual defrost switch was toggled on. |

ENTER |

Confirms a selection or saves a selection to the controller. |

Arrow Up |

Change or scroll a selection up. Pre-trip advance or test interrupt. |

Arrow Down |

Change or scroll selection downward. Pre-trip repeat backward. |

RETURN / SUPPLY |

Display non-controlling probe temperature (momentary display). |

Celsius / Fahrenheit |

Display alternate English / Metric scale (momentary display). When set to F, pressure is displayed in psig and vacuum in “/hg.” “P” appears after the value to indicate psig and “i” appears for inches of mercury. When set to C, pressure readings are in bars. “b” appears after the value to indicate bars. |

BATTERY POWER |

Initiate battery backup mode to allow set point & function code selection if AC power is not connected. |

ALT MODE |

This key is pressed to switch the functions from temperature software to the DataCORDER software. The remaining keys function the same as described above except the readings or changes are made to the DataCORDER programming. |

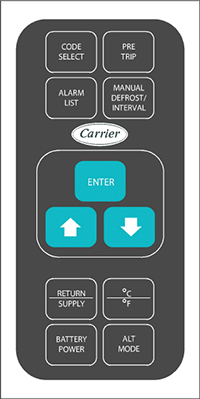

The display module (Figure 4.3) consists of two 5-digit displays and seven indicator lights. The indicator lights include:

1.Cool - White or Blue LED: Energized when the refrigerant compressor is energized.

2.Heat - Orange LED: Energized to indicate heater operation in the heat or defrost mode.

3.Defrost - Orange LED: Energized when the unit is in the defrost mode.

4.In-Range - Green LED: Energized when the controlled temperature probe is within specified tolerance of set point.

The controlling probe in the perishable range will be the SUPPLY air probe and the controlling probe in the frozen range will be the RETURN air probe.

5.Supply - Yellow LED: Energized when the supply air probe is used for control. When this LED is illuminated, the temperature displayed in the AIR TEMPERATURE display is the reading at the supply air probe. This LED will flash if dehumidification or humidification is enabled.

6.Return - Yellow LED: Energized when the return air probe is used for control. When this LED is illuminated, the temperature displayed in the AIR TEMPERATURE display is the reading at the return air probe. This LED will flash if dehumidification or humidification is enabled.

7.Alarm - Red LED: Energized when there is an active or an inactive shutdown alarm in the alarm queue.

Do not remove wire harnesses from circuit boards unless you are grounded to the unit frame with a static safe wrist strap or equivalent static drain device.

Remove the controller module and unplug all connectors before performing any arc welding on any part of the container.

Do not attempt to use an ML2i PC card in an ML3 equipped unit. The PC cards are physically different and will result in damage to the controller.

Do not attempt to service controller modules. Breaking the seal will void the warranty.

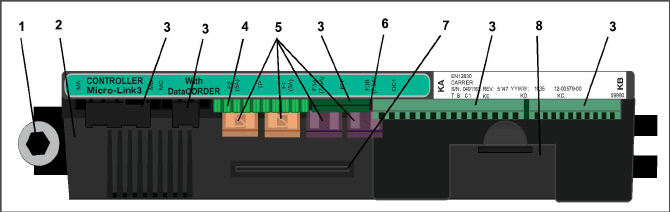

The Micro-Link 3 controller is a dual module microprocessor as shown in Figure 4.4. It is fitted with test points, harness connectors and a software card programming port.

2.Micro-Link 3 Control/DataCORDER Module

6.Control Circuit Power Connection

8.Battery Pack (Standard Location)

- - - - -

The controller software is a custom designed program that is subdivided into configuration software and operational software. The controller software performs the fol lowing functions:

a.Control supply or return air temperature to required limits, provide modulated refrigeration operation, economized operation, unloaded operation, electric heat control and defrost. Defrost is performed to clear buildup of frost and ice and ensure proper air flow across the coil.

b.Provide default independent readouts of set point and supply or return air temperatures.

c.Provide ability to read and (if applicable) modify the configuration software variables, operating software Function Codes and Alarm Code indications.

d.Provide a Pre-trip step-by-step checkout of refrigeration unit performance including: proper component operation, electronic and refrigeration control operation, heater operation, probe calibration, pressure limiting and current limiting settings.

e.Provide battery-powered ability to access or change selected codes and set point without AC power connected.

f.Provide the ability to reprogram the software through the use of a memory card.

4.2.1Configuration Software (Variables)

The configuration software is a variable listing of the components available for use by the operational soft ware. This software is factory installed in accordance with the equipment fitted and options listed on the original purchase order. Changes to the configuration soft ware are required only when a new controller has been installed or a physical change has been made to the unit such as the addition or removal of an option. A configuration variable list is provided in Table 4–4. Change to the factory-installed configuration software is achieved via a configuration card or by communications.

4.2.2Operational Software (Function Codes)

The operational software is the actual operation programming of the controller which activates or deactivates components in accordance with current unit operating conditions and operator selected modes of operation.

The programming is divided into function codes. Some of the codes are read only while the remaining codes may be user configured. The value of the user configurable codes can be assigned in accordance with user desired mode of operation. A list of the function codes is provided in Table 4–5.

To access the function codes, perform the following:

a.Press the CODE SELECT key, then press an arrow key until the left window displays the desired code number.

b.The right window will display the value of this item for five seconds before returning to the normal display mode.

c.If a longer time is desired, press the ENTER key to extend the time to five minutes.

4.3Controller Sequence and Modes of Operation

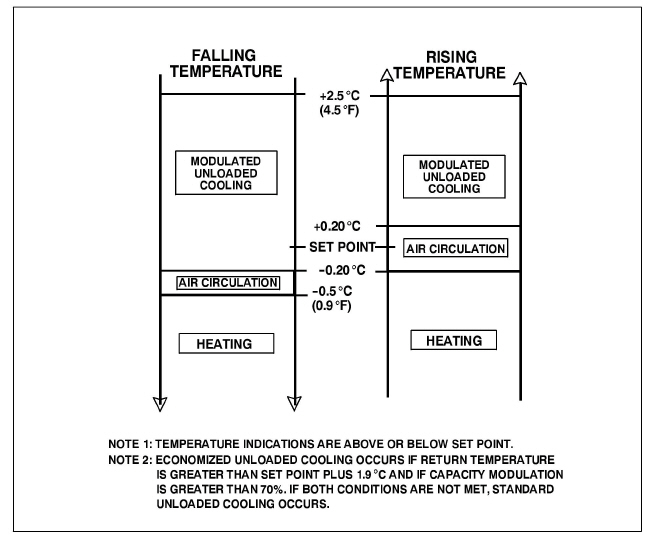

General operation sequences for cooling, heating, and defrost are provided in the following sub-paragraphs. Schematic representation of controller action is provided in Figure 4.5.

The operational software responds to various inputs. These inputs come from the temperature and pressure sensors, the temperature set point, the settings of the configuration variables and the function code assignments. The action taken by the operational software will change if any one of the inputs change. Overall interaction of the inputs is described as a “mode” of operation. The modes of operation include perishable (chill) mode and frozen mode. Descriptions of the controller interaction and modes of operation are provided in the following sub paragraphs.

4.3.1Start Up - Compressor Phase Sequence

The controller logic will check for proper phase sequencing and compressor rotation. If sequencing is allowing the compressor and three-phase evaporator fan motor to rotate in the wrong direction, the controller will energize or de-energize relay TCP as required (see Figure 8.2). Relay TCP will switch its contacts, energizing or de-energizing relays PA and PB. Relay PA is wired to energize the circuits(s) on L1, L2, and L3. Relay PB is wired to energize the circuit(s) on L3, L2, and L1, thus providing reverse rotation.

4.3.2Start Up - Compressor Bump Start

The controller logic will initiate a compressor bump start procedure to clear refrigerant from the compressor. If suction and discharge pressures have equalized, the compressor will perform three compressor bump starts. A compressor bump start may occur after a defrost has been completed.

During the procedure, the EEV will close. Relays TS, TQ, TN, TE, TV will be de-energized (opened). The result of this action will close the ESV and shut all fans off. The compressor will start for 1 second, then pause for five seconds. This sequence will be repeated two additional times. After the final bump start the unit will pre-position the EEV to correct starting position pause and startup.

4.3.3Perishable Set Point Temperature - Perishable Pulldown

When cooling from a temperature that is more than 2.5°C (4.5°F) above set point, the system will be in the perishable pulldown mode in economized operation. However, pressure and current limit functions may restrict the valve if either exceeds the preset value.

4.3.4Perishable Set Point Temperature - Standard Temperature Control Mode

The unit is capable of maintaining supply air temperature to within +/-0.2°C (+/-0.36°F) of set point. Supply air temperature is controlled by positioning of the electronic expansion valve (EEV), cycling of the digital unloader valve (DUV), cycling of the compressor and cycling of the heaters.

Once set point is reached, the unit will transition to the perishable steady state mode. This results in unloaded operation by cycling the DUV to limit capacity and maintain steady temperature control.

If the controller has determined that cooling is not required or the controller logic determines suction pressure is at the low pressure limit, the unit will transition to the perishable idle mode. The compressor is turned off and the evaporator fans continue to run to circulate air throughout the container. If temperature rises above set point +0.2°C, the unit will transition back to the perish able steady state mode

If the temperature drops to 0.5°C (0.9°F) below set point, the unit will transition to the perishable heating mode and the heaters will be energized. The unit will transition back to the perishable idle mode when the temperature rises to 0.2°C (0.4°F) below the set point and the heaters will de-energize.

4.3.5Perishable Set Point Temperature - Economy Fan Operation Mode

The economy mode is an extension of the standard mode. The mode is activated when the setting of function code Cd34 is “ON”. Economy mode is provided for power saving purposes. Economy mode could be utilized in the transportation of temperature-tolerant cargo or non-respiration items which do not require high air flow for removing respiration heat. There is no active display indicator that economy mode has been activated. To check for economy mode, perform a manual display of code Cd34.

In order to achieve economy mode, a perishable set point must be selected prior to activation. When economy mode is active, the evaporator fans will be controlled as follows:

At the start of each cooling or heating cycle, the evaporator fans will run in high speed for three minutes. They will then be switched to low speed any time the supply air temperature is within +/- 0.2°C (0.36°F) of the set point and the return air temperature is less than or equal to the supply air temperature +3°C (5.4°F). The fans will continue to run in low speed for one hour. At the end of the hour, the evaporator fans will switch back to high speed and the cycle will be repeated. If bulb mode is active, the economy fan activity will be overridden.

4.3.6Perishable Set Point Temperature Control

With configuration variable CnF26 (Heat Lockout Temperature) set to -10°C the perishable mode of operation is active with set points above -10°C (+14°F). With the variable set to -5°C, the perishable mode is active above -5°C (+23°F). Refer to Table 4–4.

When in the perishable mode, the controller maintains the supply air temperature at set point, the SUPPLY indicator light will be illuminated on the display module and the default reading on the display window will be the supply temperature sensor reading.

When the supply air temperature enters the in-range temperature tolerance (as selected at function code Cd30), the in-range light will energize.

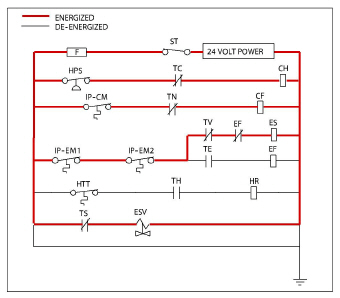

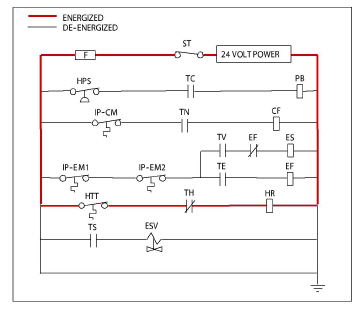

Figure 4.5 Controller Operation - Perishable Mode

4.3.7Perishable Mode Cooling - Sequence of Operation

In the Standard Perishable Mode of Operation, the evaporator motors run in high speed. In the Economy Perishable Mode, the fan speed is varied.

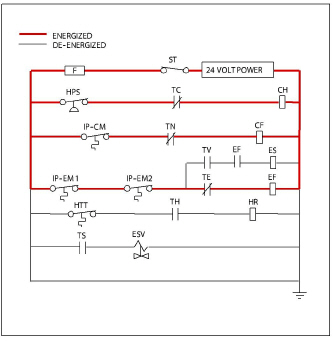

With supply air temperature above set point and decreasing, the unit will cool with the condenser fan motor (CF), compressor motor (CH), evaporator fan motors (EF) energized and the COOL light illuminated. (See Figure 4.6). Also, if current or pressure limiting is not active, the controller may close contacts TS to open the economizer solenoid valve (ESV) and place the unit in economized operation.

When the air temperature decreases to a predetermined tolerance above set point, the in-range light is illuminated.

Figure 4.6 Perishable Mode - Cooling

4.3.8Perishable Mode Heating - Sequence of Operation

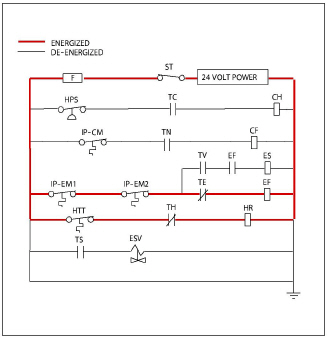

a.If the air temperature decreases 0.5°C (0.9°F) below set point, the system enters the heating mode. (See Figure 4.5). The controller closes contacts TH (see Figure 4.7) to allow power flow through the heat termination thermostat (HTT) to energize the heaters (HR). The HEAT light is also illuminated. The evaporator fans continue to run to circulate air throughout the container.

b.When the temperature rises to 0.2°C (0.4°F) below set point, contacts TH open to de-energize the heaters. The HEAT light is also de-energized. The evaporator fans continue to run to circulate air throughout the container.

c.The safety heater termination thermostat (HTT) is attached to an evaporator coil circuit and will open the heating circuit if overheating occurs.

Figure 4.7 Perishable Mode Heating

4.3.9Sequence of Operation - Perishable Mode (Capacity Trim Heat)

If the system capacity has been decreased to the lowest allowable capacity and conditions exist that warrant maximum temperature stability the controller will pulse the HR relay to energize the evaporator heaters in sequence with the compressor digital signal. Trim heat is enabled only if (12.77°C < set point < 15.55°C [54.99°F < set point < 59.99°F]) and (-6.67°C < ambient temperature < 1.66°C [19.99°F < ambient temperature < 34.99°F]).

4.3.10Perishable Mode - Dehumidification

The dehumidification mode is provided to reduce the humidity levels inside the container. The mode is activated when a humidity value is set at function code Cd33. The display module SUPPLY LED will flash ON and OFF every second to indicate that the dehumidification mode is active. Once the Mode is active and the following conditions are satisfied, the controller will activate the heat relay to begin dehumidification.

1.The humidity sensor reading is above the set point.

2.The unit is in the perishable steady state mode and supply air temperature is less than 0.25°C (0.38°F) above set point.

3.The heater debounce timer (three minutes) has timed out.

4.Heater termination thermostat (HTT) is closed.

If the above conditions are true the evaporator fans will switch from high to low speed operation. The evaporator fan speed will switch every hour thereafter as long as all conditions are met (see Bulb Mode section for different evaporator fan speed options). If any condition except item (1) becomes false OR if the relative humidity sensed is 2% below the dehumidification set point, the high speed evaporator fans will be energized.

Power is applied to the defrost heaters in the dehumidification mode. This added heat load causes the controller to open the ESV to match the increased heat load while still holding the supply air temperature very close to the set point.

Opening the ESV reduces the temperature of the evaporator coil surface, which increases the rate at which water is condensed from the passing air. Removing water from the air reduces the relative humidity. When the relative humidity sensed is 2% below the set point, the controller de-energizes the heat relay. The controller will continue to cycle heating to maintain relative humidity below the selected set point. If the mode is terminated by a condition other than the humidity sensor, e.g., an out-of-range or compressor shutdown condition, the heat relay is de-energized immediately.

Two timers are activated in the dehumidification mode to prevent rapid cycling and consequent contactor wear. They are:

1.Heater debounce timer (three minutes).

2.Out-of-range timer (five minutes).

The heater debounce timer is started whenever the heater contactor status is changed. The heat contactor remains energized (or de-energized) for at least three minutes even if the set point criteria are satisfied.

The out-of-range timer is started to maintain heater operation during a temporary out-of-range condition. If the supply air temperature remains outside of the user selected in-range setting for more than five minutes, the heaters will be de-energized to allow the system to recover. The out-of-range timer starts as soon as the temperature exceeds the in-range tolerance value set by function code Cd30.

4.3.11Perishable, Dehumidification - Bulb Mode

Bulb mode is an extension of the dehumidification mode, which allows changes to the evaporator fan speed and/or defrost termination set points.

Bulb mode is active when configuration code Cd35 is set to “Bulb”. Once the bulb mode is activated, the user may then change the dehumidification mode evaporator fan operation from the default (speed alternates from low to high each hour) to constant low or constant high speed. This is done by toggling function code Cd36 from its default of “alt” to “Lo” or “Hi” as desired. If low speed evaporator fan operation is selected, this gives the user the additional capability of selecting dehumidification set points from 60 to 95% (instead of the normal 65 to 95%).

In addition, if bulb mode is active, function code Cd37 may be set to override the previous defrost termination thermostat settings. (Refer to Section 4.3.18) The temperature at which the defrost termination thermostat will be considered “open” may be changed [in 0.1°C (0.2°F) increments] to any value between 25.6°C (78°F) and 4°C (39.2°F). The temperature at which the defrost termination thermostat is considered closed for interval timer start or demand defrost is 10°C for “open” values from 25.6°C (78°F) down to a 10°C setting. For “open” values lower than 10°C, the “closed” values will decrease to the same value as the “open” setting. Bulb mode is terminated when:

1.Bulb mode code Cd35 is set to “Nor”.

2.Dehumidification code Cd33 is set to “Off”.

3.The user changes the set point to one that is in the frozen range.

When bulb mode is disabled by any of the above, the evaporator fan operation for dehumidification reverts to “alt” and the DTS termination setting resets to the value determined by controller configuration variable CnF41.

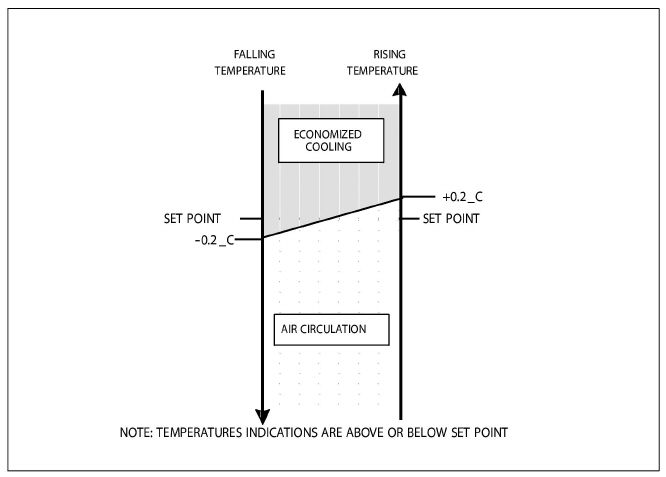

4.3.12Frozen Mode - Temperature Control

When in the frozen mode, the controller maintains the return air temperature at or below set point, the RETURN indicator light will be illuminated on the display module and the default reading on the display window will be the return air probe reading.

When the return air temperature enters the in-range temperature tolerance as selected at function code Cd30, the in-range light will energize.

Figure 4.8 Controller Operation - Frozen Mode

Frozen range cargos are not sensitive to minor temperature changes. The method of temperature control employed in this range takes advantage of this to greatly improve the energy efficiency of the unit. Temperature control in the frozen range is accomplished by cycling the compressor on and off as the load demand requires.

When temperature drops to set point minus 0.2°C and the compressor has run for at least five minutes, the unit will transition to the frozen idle mode. The compressor is turned off and the evaporator fans continue to run to circulate air throughout the container. If temperature rises above set point +0.2°C, the unit will transition back to the frozen mode cooling.

4.3.14Frozen Mode - Heat Lockout Temperature

With configuration variable CnF26 (Heat Lockout Temperature) set to -10°C the frozen mode of operation is active with set points at or below -10°C (+14°F). With the variable set to -5°C, the frozen mode is active at or below -5°C (+23°F).

If the temperature drops 10°C below set point, the unit will transition to the frozen “heating” mode, in which the evaporator fans are brought to high speed. The unit will transition back to the frozen mode cooling when the temperature rises back to the transition point.

4.3.15Frozen Mode Cooling - Sequence of Operation

a.When the return air temperature is above set point and decreasing, the unit will transition to economized cooling with the condenser fan motor (CF), compressor motor (CH), economizer solenoid valve (ESV), low speed evaporator fan motors (ES) energized and the COOL light illuminated. (See Figure 4.9).

b.When the air temperature decreases to a predetermined tolerance above set point, the in-range light is illuminated.

c.When the return air temperature decreases to 0.2°C (0.4°F) below set point, contacts TC, TS, and TN are opened to de-energize the compressor, economizer solenoid valve and condenser fan motor. The cool light is also de-energized. The EEV will close.

d.The evaporator fan motors continue to run in low speed to circulate air throughout the container. The in-range light remains illuminated as long as the return air is within tolerance of set point.

e.If return air temperature drops to 10°C (18°F) or more below set point, the evaporator fans increase to high speed.

f.When the return air temperature increases to 0.2°C (0.4°F) above set point and three minutes have elapsed, the EEV opens and contacts TC, TS and TN close to restart the compressor, open the ESV and restart the condenser fan motor. The cool light is illuminated.

The EEV and DUV are independently operated by the microprocessor. For full diagrams and legend, see Section 8.

In order to activate economy frozen mode operation, a frozen set point temperature must be selected. The economy mode is active when function code Cd34 is set to “ON”. When economy mode frozen is active, the system will perform normal frozen mode operations except that the entire refrigeration system, excluding the controller, will be turned off when the control temperature is less than or equal to the set point -2°C. After an off-cycle period of 60 minutes, the unit will turn on high speed evaporator fans for three minutes, and then check the control temperature. If the control temperature is greater than or equal to the set point +0.2°C, the unit will restart the refrigeration system and continue to cool until the previously mentioned off-cycle temperature criteria are met. If the control temperature is less than the set point +0.2°C, the unit will turn off the evaporator fans and restart another 60 minute off-cycle.

Controller function code Cd27 sets two modes for defrost initiation, either user-selected timed intervals or automatic control. The user-selected values are 3, 6, 9, 12, 24 hours, AUTO, or PuLs. Some units may be configured to allow defrost to be disabled altogether. In this case, a user-selected value of OFF will be available. The factory default for defrost is AUTO. Refer to Table 4–5.

In perishable mode, perishable-pulldown mode, or frozen-pulldown mode, automatic defrost starts with an initial defrost set to three hours and then adjusts the interval to the next defrost based on the accumulation of ice on the evaporator coil. In this way, defrosts are scheduled to occur only when necessary.

Once set point has been reached in frozen operation, the automatic selection will set the time interval to 12 hours for the first two defrosts once the return probe is reading below the frozen set point and then adjust to 24 hours thereafter.

All defrost interval times reflect the number of compressor runtime hours since the last defrost de-ice cycle. The minimum defrost interval under the automatic setting is three hours while the maximum is 24. In frozen mode the amount of wall-clock time necessary to accumulate a given amount of defrost interval time will exceed the defrost interval time by a factor of two to three depending on the compressor duty-cycle. Defrost inter val time is not accumulated in any mode until the defrost termination sensor reads less than 10°C (50°F).

If defrost does not terminate correctly and temperature reaches set point of the heat termination thermostat (HTT), the thermostat will open to de-energize the heaters. If termination does not occur within two hours, the controller will terminate defrost. An alarm will be activated to inform of a possible DTS failure.

If probe check (controller function code CnF31) is con figured to SPECIAL, the unit will proceed to the next operation (snap freeze or terminate defrost). If the code is configured to STANDARD, the unit will perform a probe check. The purpose of the probe check is to detect malfunctions in the sensed temperature. If probe check fails, the system will run for eight minutes to validate. At the end of eight minutes, probe alarms will be set or cleared based on the conditions seen.

When the return air falls to 7°C (45°F), the controller ensures that the defrost temperature sensor (DTS) reading has dropped to 10°C or below. If it has not, a DTS failure alarm is given and the defrost mode is operated by the return temperature sensor (RTS).

If controller function code CnF33 is configured to snap freeze, the controller will sequence to this operation. The snap freeze consists of running the compressor without the evaporator fans in operation for a period of 4 minutes at 100% capacity. When the snap freeze is completed, defrost is formally terminated.

4.3.18Defrost Mode - Sequence of Operation

The defrost cycle may consist of up to three distinct operations. The first is de-icing of the coil, the second is a probe check cycle and the third is snap freeze. Defrost may be initiated by any one of the following methods:

1.The manual defrost function (also manual defrost switch function, if equipped) is initiated by the user through the use of the keypad or manual defrost switch. The manual defrost function is ended by use of the DTS.

The Manual Defrost / Interval key can be used to initiate a manual defrost.

Manual Defrost/Interval key operation:

Depressing and holding the Manual Defrost / Interval key for five seconds will initiate defrost. If the Manual Defrost / Interval key is released in less than five seconds, defrost interval (code 27) shall be displayed.

2.The user sends a defrost command by communications.

3.The defrost interval timer (controller function code Cd27) reaches the defrost interval set by the user.

4.The controller probe diagnostic logic determines that a probe check is necessary based on the temperature values currently reported by the supply and return probes.

5.If the controller is programmed with the Demand Defrost option and the option is set to “IN” the unit will enter defrost if it has been in operation for more than 2.5 hours without reaching set point.

6.The system is actively in a compressor suction pressure or high pressure ratio protection mode and reduced the average system capacity below a predetermined threshold value.

Defrost may be initiated any time the defrost temperature sensor reading falls below the controller defrost terminamion thermostat set point. Defrost will terminate when the defrost temperature sensor reading rises above the defrost termination thermostat set point. The defrost termination thermostat is not a physical component. It is a controller setting that acts as a thermo stat, “closing” (allowing defrost) when the defrost temperature sensor reading is below the set point and “opening” (terminating or preventing defrost) when the sensor temperature reading is above set point. When the unit is operating in bulb mode (refer to Section 4.3.11), special settings may be applicable.

If the controller is programmed with the Lower DTT set ting option, the defrost termination thermostat set point may be configured to the default of 25.6°C (78°F) or lowered to 18°C (64°F). When a request for defrost is made through the manual defrost switch, communications or probe check the unit will enter defrost if the de frost temperature thermostat reading is at or below the defrost termination thermostat setting. Defrost will terminate when the defrost temperature sensor reading rises above the defrost termination thermostat setting. When a request for defrost is made with the defrost interval timer or by demand defrost, the defrost temperature setting must be below 10°C (50°F).

When the defrost mode is initiated, the controller closes the EEV, opens contacts TC, TN, and TE (or TV) to de-energize the compressor, condenser fan and evaporator fans. The COOL light is also de-energized. The controller then closes contacts TH to supply power to the heaters. The defrost light is illuminated. When the defrost temperature sensor reading rises to the defrost termination thermostat setting, the de-icing operation is terminated.

The EEV and DUV are independently operated by the microprocessor. For full diagrams and legend, see Section 8.

Pulse defrost logic periodically turns on the evaporator fans to circulate warm air around the drain line system, this prevents water re-freezing during a defrost cycle.

To enable Defrost Pulsing, the user will scroll to Function Code 27, select “PuLs” and press the Enter key. Once “PuLs” has been selected the user will then scroll to Function Code 60 and select the “Pulse Logic Set Point Engagement Temperature”. The selections are from 0.0°C (32°F) to -18°C (0°F). At the selected Engagement set point or below, “PuLs” will be active, and the evaporator fans may turn on. At set points above the selected Engagement set point, “AUTO” defrost will be active.

Default setting for “PuLs” is -18°C (0°F). The unit will reset to the default setting at the next PTI or Trip Start.

The default defrost interval for “PuLs” will be every 6 hours. Defrost termination setting for “PuLs” is set to 20°C (68°F).

During defrost the evaporator fans will cycle ON Low Speed once DTS reaches 0°C (32°F) and STS is below -5°C (23°F). Once the evaporator fans cycle ON the controller will monitor STS at 1 second intervals and calculate the difference between the current STS reading and the previous STS reading.

If STS becomes warmer that -5°C (23°F) or the calculated difference of STS remains below 0.1°C (0.18°F) for 10 consecutive readings or DTS reaches 20°C (68°F), the evaporator fans will turn off for 3 minutes. At the end of 3 minutes, the controller will begin checking the conditions for evaporator fans “PuLs” operation again.

4.4Protection Modes of Operation

Opening of an evaporator fan internal protector will shut down the unit.

Function code Cd29 may be operator set to select action the controller will take upon system failure. The factory default is full system shutdown. Refer to Table 4–5.

Function codes Cd31(Stagger Start, Offset Time) and Cd32 (Current Limit) may be operator set to control start up sequence of multiple units and operating current draw. The factory default allows on demand starting (no delay) of units and normal current draw. Refer to Table 4–5.

4.4.4Compressor High Temperature, Low Pressure Protection

The controller monitors compressor discharge pres sure, and temperature and suction pressure. If dis charge pressure or temperature rises above the allowed limit or suction pressure falls below the allowed limit, the compressor will be cycled off and on every 3 minutes. Condenser and evaporator fans continue to operate during the compressor off cycle.

If high compressor dome temperature occurs, the controller will allow additional refrigerant to be released into the system in order to provide cooling to the evaporator coil and compressor dome. The controller is alerted to high compressor dome temperatures via the CPDS when the ambient temperature is greater than 43.3°C, the return air temperature is less than -17.5°C and if the compressor discharge temperature is greater than 117.7°C.

Dome temperature control logic will disengage when return air temperature and ambient temperature return to allowed limits or when compressor turns off.

If the suction pressure low limit is triggered, the DUV will energize to raise the suction pressure.

4.4.5Perishable Mode - System Pressure Regulation

In perishable mode, system pressures may need to be regulated at ambient temperatures of 20°C (68°F) and below. Once below this ambient temperature, the con denser fan may cycle on and off based on limits imposed for discharge pressure. For extremely cold ambient temperatures, -18°C (0°F), heater cycling may occur within normal system operation based on discharge pressure limits.

When configuration variable CnF17 (Discharge Temperature Sensor) is set to “In” and CnF48 (Condenser Fan Switch Override) is set to “On”, the condenser fan switch override logic is activated. If condenser cooling water pressure is sufficient to open the water pressure switch (de-energizing the condenser fan) when water flow or pressure conditions are not maintaining dis charge temperature, the logic will energize the condenser fan as follows:

1.If the DUV is less than 80% open when the controller calls for it to be100% open, the condenser fan is energized. When the DUV is 100% open, the fan will de-energize.

2.If DPT reading is invalid or out of range (AL 65), the condenser fan is energized and will remain energized until system power is cycled.

3.If the system is running on condenser fan override and the high pressure switch opens, the condenser fan is energized and will remain energized until the system power is cycled.

Alarm display is an independent controller software function. If an operating parameter is outside of expected range or a component does not return the correct signals back to the controller, an alarm is generated. A listing of the alarms is provided in Table 4–6.

The alarm philosophy balances the protection of the refrigeration unit and that of the refrigerated cargo. The action taken when an error is detected always considers the survival of the cargo. Rechecks are made to confirm that an error actually exists.

Some alarms requiring compressor shutdown have time delays before and after to try to keep the compressor on line. An example is alarm code “LO”, (low main voltage), when a voltage drop of over 25% occurs, an indication is given on the display, but the unit will continue to run.

a.The red alarm light will illuminate for alarm code numbers 15, 17, 20, 21, 22, 23, 24, 25, 26, and 27.

b.If a detectable problem exists, its alarm code will be alternately displayed with the set point on the left display.

c.The user should scroll through the alarm list to deter mine what alarms exist or have existed. Alarms must be diagnosed and corrected before Alarm List can be cleared.

a.While in the Default Display mode, press the ALARM LIST key. This accesses the Alarm List Display Mode, which displays any alarms archived in the alarm queue.

b.The alarm queue stores up to 16 alarms in the sequence in which they occurred. The user may scroll through the list by depressing an ARROW key.

c.The left display will show “AL##”, where ## is the alarm number sequentially in the queue.

d.The right display will show the actual alarm code. “AA##” will display for an active alarm, where “##” is the alarm code. Or “IA##” will display for an inactive alarm, See Table 4–6.

e.“END” is displayed to indicate the end of the alarm list if any alarms are active.

f.“CLEAr” is displayed if all alarms are inactive. The alarm queue may then be cleared by pressing the ENTER key. The alarm list will clear and “-----” will be displayed.

AL26 is active when all of the sensors are not responding. Check the connector at the back of the controller; if it is loose or unplugged, reconnect it, then run a pre-trip test (P5) to clear AL26.

Pre-trip Diagnostics is an independent controller function that suspends normal refrigeration controller activities and provides preprogrammed test routines. The test routines include Auto Mode testing, which automatically preforms a pre-programmed sequence of tests, or Manual Mode testing, which allows the operator to select and run any of the individual tests.

Pre-trip inspection should not be per formed with critical temperature cargoes in the container.

When Pre-trip key is pressed, economy, de humidification and bulb mode will be deactivated. At the completion of Pre-trip activity, economy, dehumidification and bulb mode must be reactivated.

Testing may be initiated by use of the keypad or via communication, but when initiated by communication the controller will execute the entire battery of tests (auto mode).

At the end of a pre-trip test, the message “P,” “rSLts” (pretest results) will be displayed. Pressing the ENTER key will allow the user to see the results for all subtests. The results will be displayed as “PASS” or “FAIL” for all the tests run to completion.

A detailed description of the pre-trip tests and test codes is provided in Table 4–7. Detailed operating instructions are provided in Section 5.7.

The Carrier Transicold “DataCORDER” software is integrated into the controller and serves to eliminate the temperature recorder and paper chart. The DataCORDER functions may be accessed by keypad selections and viewed on the display module. The unit is also fitted with interrogation connections (see Figure 4.1) which may be used with the Carrier Transicold Data Reader to download data. A personal computer with Carrier Transicold DataLINE software may also be used to download data and configure settings. The DataCORDER consists of:

•Configuration Software

•Operational Software

•Data Storage Memory

•Real Time Clock (with internal battery backup)

•Six Thermistor Inputs

•Interrogation Connections

•Power Supply (battery pack)

•The DataCORDER performs the following functions:

a.Logs data at 15, 30, 60, or 120 minute intervals and stores two years of data (based on one-hour interval).

b.Records and displays alarms on the display module.

c.Records results of pre-trip testing.

d.Records DataCORDER and temperature control software generated data and events as follows:

•Container ID Change

•Software Upgrades

•Alarm Activity

•Battery Low (battery pack)

•Data Retrieval

•Defrost Start and End

•Dehumidification Start and End

•Power Loss (with and without battery pack)

•Power Up (with and without battery pack)

•Remote Probe Temperatures in the Container (USDA Cold treatment and Cargo probe recording)

•Return Air Temperature

•Set Point Change

•Supply Air Temperature

•Real Time Clock Battery (internal battery) Replacement

•Real Time Clock Modification

•Trip Start

•ISO Trip Header (When entered via Interrogation program)

•Economy Mode Start and End

•“Auto 1/Auto 2/Auto 3" Pre-trip Start and End

•Bulb Mode Start

•Bulb Mode Changes

•Bulb Mode End

•USDA Trip Comment

•Humidification Start and End

•USDA Probe Calibration

•Fresh Air Vent Position

- - - - -

The DataCORDER Software is subdivided into the Operational Software, Configuration Software, and the Data Memory.

The Operational Software reads and interprets inputs for use by the Configuration Software. The inputs are labeled Function Codes. Controller functions (see Table 4–8) which the operator may access to examine the current input data or stored data. To access these codes, do the following:

1.Press the ALT. MODE and CODE SELECT keys.

2.Press an arrow key until the left window displays the desired code number. The right window will display the value of this item for five seconds before returning to the normal display mode.

3.If a longer display time is desired, press the ENTER key to extend the display time to five minutes.

The configuration software controls the recording and alarm functions of the DataCORDER. Reprogramming to the factory-installed configuration is achieved via a configuration card. Changes to the unit DataCORDER configuration may be made using the DataLINE interrogation software. A listing of the configuration variables is provided in Table 4–2. Descriptions of Data CORDER operation for each variable setting are provided in the following paragraphs.

4.7.3Sensor Configuration (dCF02)

Two modes of operation may be configured, the Standard Mode and the Generic Mode.

a.Standard Mode

In the standard mode, the user may configure the DataCORDER to record data using one of seven standard configurations. The seven standard configuration variables, with their descriptions, are listed in Table 4–3.

The inputs of the six thermistors (supply, return, USDA #1, #2, #3, and cargo probe) and the humidity sensor input will be generated by the DataCORDER. See Figure 4.11.

The DataCORDER software uses the supply and return recorder sensors (SRS, RRS). The temperature control software uses the supply and return temperature sensors (STS, RTS).

b.Generic Mode

The generic recording mode allows user selection of the network data points to be recorded. The user may select up to a total of eight data points for recording. A list of the data points available for recording follows. Changing the configuration to generic and selecting which data points to record may be done using the Carrier Transicold Data Retrieval Program.

1.Control mode

2.Control temperature

3.Frequency

4.Humidity

5.Phase A current

6.Phase B current

7.Phase C current

8.Main voltage

9.Evaporator expansion valve percentage

10.Discrete outputs (Bit mapped - require special handling if used)

11.Discrete inputs (Bit mapped - require special handling if used)

12.Ambient sensor

13.Evaporator temperature sensor

14.Compressor discharge sensor

15.Return temperature sensor (RTS)

16.Supply temperature sensor (STS)

17.Defrost temperature sensor

18.Discharge pressure transducer

19.Suction pressure transducer

20.Condenser pressure transducer

21.Vent position sensor (VPS)

- - - - -

The user may select four different time intervals between data recordings. Data is logged at exact intervals in accordance with the real time clock. The clock is factory set at Greenwich Mean Time (GMT).

4.7.5Thermistor Format (dCF04)

The user may configure the format in which the thermistor readings are recorded. The short resolution is a 1 byte format and the long resolution is a 2 byte format. The short requires less memory and records temperature with variable resolutions depending on temperature range. The long records temperature in 0.01°C (0.02°F) steps for the entire range.

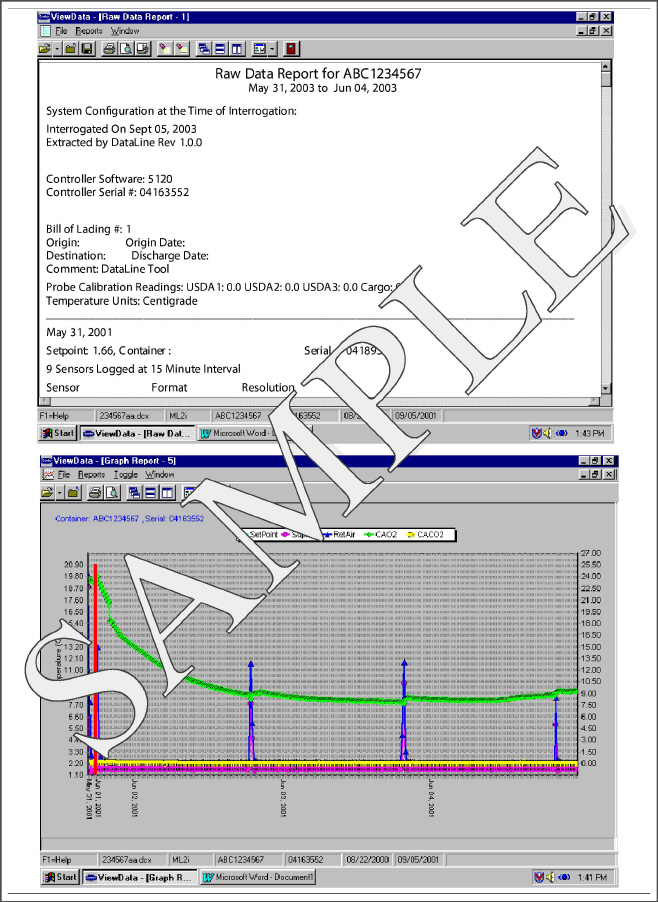

Figure 4.11 Standard Configuration Download Report

4.7.6Sampling Type (dCF05 & dCF06)

Three types of data sampling are available: average, snapshot and USDA. When configured to average, the average of readings taken every minute over the recording period is recorded. When configured to snapshot, the sensor reading at the log interval time is recorded. When USDA is configured, the supply and return temperature readings are averaged and the three USDA probe readings are snapshot.

4.7.7Alarm Configuration (dCF07 - dCF10)

The USDA and cargo probe alarms may be configured to OFF, ON or AUTO.

If a probe alarm is configured to OFF, the alarm for this probe is always disabled.

If a probe alarm is configured to ON, the associated alarm is always enabled.

If the probes are configured to AUTO, they act as a group. This function is designed to assist users who keep their DataCORDER configured for USDA recording, but do not install the probes for every trip. If all the probes are disconnected, no alarms are activated. As soon as one of the probes is installed, all of the alarms are enabled and the remaining probes that are not installed will give active alarm indications.

The DataCORDER may be powered up in any one of four ways:

1.Normal AC power: The DataCORDER is powered up when the unit is turned on via the stop-start switch.

2.Controller DC battery pack power: If a battery pack is installed, the DataCORDER will power up for communication when an interrogation cable is plugged into an interrogation receptacle.

3.External DC battery pack power: A 12 volt battery pack may also be plugged into the back of the interrogation cable, which is then plugged into an interrogation port. No controller battery pack is required with this method.

4.Real Time Clock demand: If the DataCORDER is equipped with a charged battery pack and AC power is not present, the DataCORDER will power up when the real time clock indicates that a data recording should take place. When the DataCORDER is finished recording, it will power down.

During DataCORDER power-up, while using battery-pack power, the controller will perform a hardware voltage check on the battery. If the hardware check passes, the controller will energize and perform a software battery voltage check before DataCORDER logging. If either test fails, the real time clock battery power-up will be disabled until the next AC power cycle. Further Data CORDER temperature logging will be prohibited until that time.

An alarm will be generated when the battery voltage transitions from good to bad indicating that the battery pack needs recharging. If the alarm condition persists for more than 24 hours on continuous AC power, the battery pack needs replacement.

The DataCORDER will record the initiation of a pre-trip test (refer to Section 4.6) and the results of each of the tests included in pre-trip. The data is time-stamped and may be extracted via the Data Retrieval program. Refer to Table 4–9 for a description of the data stored in the DataCORDER for each corresponding Pre-trip test.

4.7.10DataCORDER Communications

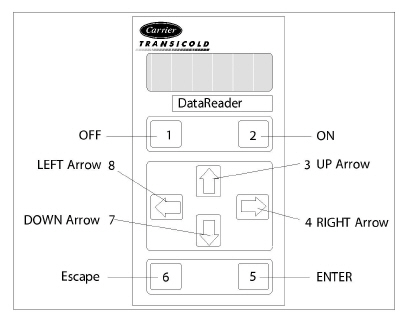

Data retrieval from the DataCORDER can be accomplished by using one of the following: DataReader, DataLINE, or a communications interface module.

A DataReader, DataLINE or a communications interface module display of Communication Failed is caused by faulty data transfer between the DataCORDER and the data retrieval device. Common causes include:

1.Bad cable or connection between DataCORDER and data retrieval device.

2.PC communication port(s) unavailable or mis-assigned.

3.Chart Recorder Fuse (FCR) blown.

Configuration identification for the models covered herein may be obtained on the Container Products Group Information Center by authorized Carrier Transicold Service Centers.

The Carrier Transicold Data Reader (see Figure 4.12) is a simple to operate handheld device designed to extract data from the DataCORDER and upload it to a PC. The Data Reader has the ability to store multiple data files. Refer to Data Retrieval manual 62-10629 for a more detailed explanation of the DataReader.

The DataBANKTM card is a PCMCIA card that interfaces with the controller through the programming slot and can download the data at a much faster rate, when compared to the PC or DataReader. Files downloaded to DataBANK card files are accessible through an Omni PC Card Drive. The files can then be viewed using the DataLINE software.

The DataLINE software for a personal computer is supplied on both floppy disks and CD. This software allows interrogation, configuration variable assignment, screen view of the data, hard copy report generation, cold treatment probe calibration, and file management. Refer to Data Retrieval manual 62-10629 for a more detailed explanation of the DataLINE interrogation soft ware. The DataLINE manual may be found on the Internet at www.container.carrier.com.

d.Communications Interface Module

The communications interface module is a slave module, which allows communication with a master central monitoring station. The module will respond to communication and return information over the main power line.

With a communications interface module installed, all functions and selectable features that are accessible at the unit may be performed at the master station. Retrieval of all DataCORDER reports may also be performed. Refer to the master system technical manual for further information.

Sustained cold temperature has been employed as an effective post-harvest method for the control of Mediterranean and certain other tropical fruit flies. Exposing infested fruit to temperatures of 2.2°C (36°F) or below for specific periods results in the mortality of the various stages of this group of insects.

In response to the demand to replace fumigation with this environmentally sound process, Carrier has integrated Cold Treatment capability into its microprocessor system. These units have the ability to maintain supply air temperature within one quarter degree Celsius of set point and record minute changes in product temperature within the DataCORDER memory, thus meeting USDA criteria. Information on USDA is provided in the following sub-paragraphs.

A special type of recording is used for USDA cold treatment purposes. Cold treatment recording requires three remote temperature probes be placed at prescribed locations in the cargo. Provision is made to connect these probes to the DataCORDER via receptacles located at the rear left-hand side of the unit. Four or five receptacles are provided. The four 3-pin receptacles are for the probes. The 5-pin receptacle is the rear connection for the Interrogator. The probe receptacles are sized to accept plugs with tricam coupling locking de vices. A label on the back panel of the unit shows which receptacle is used for each probe.

The standard DataCORDER report displays the supply and return air temperatures. The cold treatment report displays USDA #1, #2, #3, and the supply and return air temperatures. Cold treatment recording is backed up by a battery so recording can continue if AC power is lost.

4.7.12USDA/ Message Trip Comment

A special feature in DataLINE allows the user to enter a USDA (or other) message in the header of a data report. The maximum message length is 78 characters. Only one message will be recorded per day.

4.7.13USDA Cold Treatment Procedure

The following is a summary of the steps required to initiate a USDA Cold Treatment:

a.Calibrate the three USDA probes by ice bathing the probes and performing the calibration function with the DataReader or DataLINE. This calibration procedure determines the probe offsets and stores them in the controller for use in generating the cold treatment report. Refer to the Data Retrieval manual 62-10629 for more details.

b.Pre-cool the container to the treatment temperature or below.

c.Install the DataCORDER module battery pack (if not already installed).

d.Place the three probes. The probes are placed into the pulp of the product (at the locations defined in the following table) as the product is loaded.

Sensor 1 |

Place in pulp of the product located next to the return air intake. |

Sensor 2 |

Place in pulp of the product five feet from the end of the load for 40 foot containers, or three feet from the end of the load for 20 foot containers. This probe should be placed in a center carton at one-half the height of the load. |

Sensor 3 |

Place in pulp of product five feet from the end of the load for 40 foot containers or three feet from the end of the load for 20 foot containers. This probe should be placed in a carton at a side wall at one-half the height of the load. |

e.To initiate USDA recording, connect the personal computer and perform the configuration as follows, using the DataLINE software:

1.Enter ISO header information.

2.Enter a trip comment if desired.

3.Configure the DataCORDER for five probes (s, r, P1, P2, P3) (dcf02=5).

4.Configure the logging interval for one hour.

5.Set the sensor configuration to “USDA”.

6.Configure for two byte memory storage format (dcf04=LONG).

7.Perform a “trip start”.

The alarm display is an independent DataCORDER function. If an operating parameter is outside of the expected range or a component does not return the correct values to the DataCORDER, an alarm is generated. The DataCORDER contains a buffer of up to eight alarms. A listing of the DataCORDER alarms is provided in Table 4–10, page. Refer to Section 4.7.7 for configuration information.

a.While in the Default Display mode, press the ALT. MODE & ALARM LIST keys. This accesses the DataCORDER Alarm List Display Mode, which displays any alarms stored in the alarm queue.

b.To scroll to the end of the alarm list, press the UP ARROW. Depressing the DOWN ARROW key will scroll the list backward.

c.The left display will show “AL#” where # is the alarms number in the queue. The right display will show “AA##”, if the alarm is active, where ## is the alarm number. “IA##”, will show if the alarm is inactive

d.“END” is displayed to indicate the end of the alarm list if any alarms are active. “CLEAr” is displayed if all the alarms in the list are inactive.

e.If no alarms are active, the alarm queue may be cleared. The exception to this rule is the DataCORDER alarm queue Full alarm (AL91), which does not have to be inactive in order to clear the alarm list. To clear the alarm list:

1.Press the ALT. MODE & ALARM LIST keys.

2.Press the UP/DOWN ARROW key until “CLEAr” is displayed.

3.Press the ENTER key. The alarm list will clear and “-----” will be displayed.

4.Press the ALARM LIST key. “AL” will show on the left display and “-----” on the right display when there are no alarms in the list.

5.Upon clearing of the alarm queue, the alarm light will be turned off.

DataLINE provides the user with an interface to view/ modify current settings of the ISO trip header through the ISO Trip Header screen.

The ISO Trip Header screen is displayed when the user clicks on the “ISO Trip Header” button in the “Trip Functions” Group Box on the System Tools screen.

F9 function - Provides the user with a shortcut for manually triggering the refresh operation. Before sending modified parameter values, the user must ensure that a successful connection is established with the controller.

If the connection is established with the DataCORDER, the current contents of the ISO Trip Header from the DataCORDER will be displayed in each field. If the connection is not established with the DataCORDER, all fields on the screen will be displayed as “Xs”. If at any time during the display of the ISO Trip Header screen the connection is not established or is lost, the user is alerted to the status of the connection.

After modifying the values and ensuring a successful connection has been made with the DataCORDER, click on the “Send” button to send the modified parameter values.

The maximum allowed length of the ISO Trip Header is 128 characters. If the user tries to refresh the screen or close the utility without sending the changes made on the screen to the DataCORDER, the user is alerted with a message.

Configuration numbers not listed are not used in this application. These items may appear when loading configuration software to the controller but changes will not be recognized by the controller programming.

Code |

Title |

Description |

|---|---|---|

If the function is not applicable, the display will read “-----” |

||

Display Only Functions |

||

Cd01 |

Capacity Modulation (%) |

Displays the DUV percent closed. The right display reads 100% when the valve is fully closed. The valve will usually be at 10% on start up of the unit except in very high ambient temperatures. |

Cd03 |

Compressor Motor Current |

The current sensor measures current draw in lines L1 & L2 by all of the high voltage components. It also measures current draw in compressor motor leg T3. The compressor leg T3 current is displayed. |

Cd04 Cd05 Cd06 |

Line Current Phase A Line Current Phase B Line Current Phase C |

The current sensor measures current on two legs. The third unmeasured leg is calculated based on a current algorithm. The current measured is used for control and diagnostic purposes. For control processing, the highest of the Phase A and B current values is used for current limiting purposes. For diagnostic processing, the current draws are used to monitor component energization. Whenever a heater or a motor is turned ON or OFF, the current draw increase/reduction for that activity is measured. The current draw is then tested to determine if it falls within the expected range of values for the component. Failure of this test will result in a pre-trip failure or a control alarm indication. |

Cd07 |

Main Power Voltage |

The main supply voltage is displayed. |

Cd08 |

Main Power Frequency |

The value of the main power frequency is displayed in Hertz. The frequency displayed will be halved if either fuse F1 or F2 is bad (alarm code AL21). |

Cd09 |

Ambient Temperature |

The ambient sensor reading is displayed. |

Cd10 |

Evaporator Temperature Sensor |

Evaporator temperature sensor reading is shown on the right display. |

Cd11 |

Compressor Dome Temperature / Discharge Temperature |

Compressor discharge temperature sensor reading, using compressor dome temperature, is displayed. |

Cd12 |

Compressor Suction Port Pressure / Evaporator Pressure |

Reading for evaporator pressure transducer (EPT) is shown on the left display; Press ENTER at Cd12 to show reading for compressor suction port pressure on right display. |

Cd14 |

Compressor Discharge Pressure |

Compressor discharges pressure transducer reading is displayed. |

Cd15 |

Digital Unloader Valve |

The status of the valve is displayed (Open - Closed). |

Cd16 |

Compressor Motor Hour Meter / Unit Run Time Hour Meter |

This code displays the compressor motor hours. User can view unit run time by pressing the ENTER key while in Cd16. Total hours are recorded in increments of 10 hours (i.e., 3000 hours is displayed as 300). The Compressor Motor Hour Meter display can be reset to 0 by pressing and holding the ENTER key for 5 seconds. The Unit Run Time Hour Meter cannot be reset. |

Cd17 |

Relative Humidity % |

Humidity sensor reading is displayed. This code displays the relative humidity, as a percent value. |

Cd18 |

Software Revision Number |

The software revision number is displayed. |

Cd19 |

Battery Check |

This code checks the Controller / DataCORDER battery pack. While the test is running, “btest” will flash on the right display, followed by the result. “PASS” will be displayed for battery voltages greater than 7.0 volts. “FAIL” will be displayed for battery voltages between 4.5 and 7.0 volts, and “-----” will be displayed for battery volt ages less than 4.5 volts. After the result is displayed for four seconds, “btest” will again be displayed, and the user may continue to scroll through the various codes. |

Cd20 |

Config / Model Number |

This code indicates the dash number of the model for which the Controller is configured (i.e., if the unit is a 69NT40-551-100, the display will show “51100”). To display controller configuration database information, press ENTER. Values in “CFYYMMDD” format are displayed if the controller was configured with a configuration card or with a valid OEM serial port configuration update; YYMMDD represents the publication date of the model configuration database. |

Cd21 |

Capacity Mode |

The mode of operation is displayed (Unloaded - Standard - Economized). |

Cd22 |

Compressor State |

The status of the compressor is displayed (Off, On). |

Cd23 |

Evaporator Fan State |

Displays the current evaporator fan state (high, low or off). |

Cd25 |

Compressor Run Time Remaining Until Defrost |

This code displays the time remaining until the unit goes into defrost (in tenths of an hour). This value is based on the actual accumulated compressor running time. |

Cd26 |

Defrost Temperature Sensor Reading |

Defrost temperature sensor reading is displayed. |

Configurable Functions |

||

NOTE: Function codes Cd27 through Cd37 are user-selectable functions. The operator can change the value of these functions to meet the operational needs of the container. |

||

Cd27 |

Defrost Interval (Hours or Automatic) |

There are three modes for defrost initiation: user-selected timed intervals, automatic control, and PuLs. The user-selected values are (OFF), 3, 6, 9, 12, 24 hours, AUTO, or PuLs. The factory default is AUTO. Automatic defrost starts with an initial defrost at three hours, then the interval to the next defrost is adjusted based on the accumulation of ice on the evaporator coil. Following a start-up or after termination of a defrost, the time will not begin counting down until the defrost temperature sensor (DTS) reading falls below set point. If the reading of DTS rises above set point any time during the timer count down, the interval is reset and the countdown begins over. If DTS fails, alarm code AL60 is activated and control switches over to the return temperature sensor. The controller will act in the same manner as with the DTS except the return temperature sensor reading will be used. For information on PuLs, refer to Defrost Pulsing Section 4.3.19. Defrost Interval Timer Value (Configuration variable CnF23): If the software is configured to “SAv” (save) for this option, the value of the defrost interval timer will be saved at power down and restored at power up. This option prevents short power interruptions from resetting an almost expired defrost interval, and possibly delaying a needed defrost cycle. NOTE: The defrost interval timer counts only during compressor run time. |

Cd28 |

Temperature Units (Degrees C or Degrees F) |

This code determines the temperature units (C or F) that will be used for all temperature displays. The user selects C or F by selecting function code Cd28 and pushing the ENTER key. The factory default value is Celsius units. NOTE: This function code will display “-----” if CnF34 is set to F. |

Cd29 |

Failure Action (Mode) |

If all of the control sensors are out of range (alarm code AL26) or there is a probe circuit calibration failure (alarm code AL27), the unit will enter the shutdown state defined by this setting. The user selects one of four possible actions as follows: A - Full Cooling (Compressor is on, economized operation.) B - Partial Cooling (Compressor is on, standard operation.) C - Evaporator Fan Only (Evaporator fans on high speed, not applicable with frozen set points.) D - Full System Shutdown - Factory Default (Shut down every component in unit.) |

Cd30 |

In-Range Tolerance |

The in-range tolerance will determine the band of temperatures around the set point which will be designated as in-range. If the control temperature is in-range, the in-range light will be illuminated. There are four possible values: 1 = +/- 0.5°C (+/- 0.9°F) 2 = +/- 1.0°C (+/- 1.8°F) 3 = +/- 1.5°C (+/- 2.7°F) 4 = +/- 2.0°C (+/- 3.6°F) - Factory Default |

Cd31 |

Stagger Start Offset Time (Seconds) |

The stagger start offset time is the amount of time that the unit will delay at start-up, thus allowing multiple units to stagger their control initiation when all units are powered up together. The eight possible offset values are: 0 (Factory Default), 3, 6, 9, 12, 15, 18, or 21 seconds |

Cd32 |

System Current Limit (Amperes) |

The current limit is the maximum current draw allowed on any phase at any time. Limiting the unit's current reduces the load on the main power supply. When desirable, the limit can be lowered. Note, however, that capacity is also reduced. The five values for 460 VAC operation are: 15, 17, 19, 21, or 23 amperes. The factory default setting is 21 amperes. |

Cd33 |

Humidity Setpoint |

Relative humidity set point is available only on units configured for dehumidification. When the mode is activated, the control probe LED flashes on and off every second to alert the user. If not configured, the mode is permanently deactivated and “-----” will display. The value can be set to “OFF,” “TEST,” or a range of 65 to 95% relative humidity in increments of 1%. [If bulb mode is active (code Cd35) and “Lo” speed evaporator motors are selected (code Cd36), then set point ranges from 60 to 95%.] When “TEST” is selected or test set point is entered, the heat LED should illuminate, indicating that dehumidification mode is activated. After a period of five minutes in the “TEST” mode has elapsed, the previously selected mode is reinstated. |

Cd34 |

Economy Mode (On-Off) |

Economy mode is a user selectable mode of operation provided for power saving purposes. |

Cd35 |

Bulb Mode |

Bulb mode is a user selectable mode of operation that is an extension of dehumidification control (Cd33). If dehumidification is set to “Off,” code Cd35 will display “Nor” and the user will be unable to change it. After a dehumidification set point has been selected and entered for code Cd33, the user may change code Cd35 to “bulb.” After bulb has been selected and entered, the user may utilize function codes Cd36 and Cd37 to make the desired changes. |

Cd36 |

Evaporator Fan Speed |

This code is enabled only if in the dehumidification mode (code Cd33) and bulb mode (Cd35) has been set to “bulb.” If these conditions are not met, “alt” will be displayed (indicating that the evaporator fans will alternate their speed) and the display cannot be changed. If a dehumidification set point has been selected along with bulb mode, “alt” may be selected for alternating speed, “Lo” for low speed evaporator fan only, or “Hi” for high speed evaporator fan only. If a setting other than “alt” has been selected and bulb mode is deactivated in any manner, the selection reverts back to “alt.” |

Cd37 |

Variable DTT Setting (Bulb Mode) |

This code, as with function code Cd36, is used in conjunction with bulb mode and dehumidification. If bulb mode is active, this code allows the user to change the temperature above which defrost will terminate. It allows the user to change the setting within a range of 4°C to 25.6°C in 0.1°C (0.2°F) increments. This value is changed using the UP/DOWN ARROW keys, followed by the ENTER key when the desired value is displayed. If bulb mode is deactivated, the DTS setting re turns to the default. |

Cd38 |

Secondary Supply Temperature Sensor |

Code Cd38 will display the current supply recorder sensor (SRS) reading for units configured for four probes. If the unit is configured with a DataCORDER, Cd38 will display “-----.” If the DataCORDER suffers a failure, (AL55) Cd38 will display the supply recorder sensor reading. |

Cd39 |

Secondary Return Temperature Sensor |

Code Cd39 will display the current return recorder sensor (RRS) reading for units configured for four probes. If the unit is configured with a DataCORDER, Cd39 will display “-----.” If the DataCORDER suffers a failure, (AL55) Cd39 will display the return recorder sensor reading. |

Cd40 |

Container Identification Number |

Code Cd40 is configured at commissioning to read a valid container identification number. The reading will not display alpha characters; only the numeric portion of the number will display. |

Cd41 |

Valve Override |

SERVICE FUNCTION: This code is used for troubleshooting, and allows manual positioning of the economizer solenoid valve, electronic expansion valve, and digital unloader valve. Provides readings such as: Percent Capacity, EEV, Capacity Mode, LIV, and DUV. Refer to Section 7.16 for operating instructions. |

Cd43 |

eAutoFresh Mode |

Code Cd43 is used to select the mode of operation for the eAutoFresh slides. Associated parameters can also be selected from submenus: OFF, USER, DELAY, TEST and gASLM. If the unit is not configured for eAutoFresh, Cd43 will display “-----.” |

Cd44 |

eAutoFresh Values / CO2 Sensor Status |

Code Cd44 displays the eAutoFresh CO2 and O2 values (CO2 and O2) and CO2 and O2 limits (CO2LIM and O2LIM), respectively. If the unit is not configured for eAutoFresh, Cd44 will display “-----.” |

Cd45 |

Vent Position Sensor (VPS) Position |

Unless AL50 is active or CnF47 is OFF, the fresh air flow (CMH/CFM) is displayed. This function code will automatically activate for 30 seconds and display when a vent position change occurs. |

Cd46 |

Airflow Display Units |

This code displays the airflow units to be displayed for Cd 45. Options are CF, CM, or bOth (dependent on the setting of Cd28 or pressing of the C/F key). |

Cd47 |

Variable Economy Temperature Setting |

Code Cd47 is used with optional economy mode. Values are 0.5°C-4.0°C, default is 3.0°C. If unit is not configured for economy mode, “----” will be displayed. |

Cd48 |

Dehumidification / Bulb Cargo Mode Parameter Selection |

Code Cd48 is used both when dehumidification set point is set above 65% RH and below 64% RH. When dehumidification set point is set above 65% RH, select goes to LO if it had been set to hi. When dehumidification set point is set below 64% RH, select goes to Alt if it had been set to LO. |

Cd49 |

Days Since Last Successful Pre-trip |

Code Cd49 will display the time period (days) since the last successful pre-trip completion. Press ENTER repeatedly to display last pre-trip completion in Auto, Auto 1, and Auto 2 modes. |

Cd50 |

Quest Enable / Disable |

Code 50 allows selection of CCPC mode. The user can press ENTER, then arrow keys, then ENTER again to enable (On) or suspend (OFF) CCPC mode. If CCPC operation is On, it may be suspended due to one of the following conditions: “SEtPt” =Set point is too low. “CAHUM”= CA or humidity control is active “ACT”=ACT is active. “FAIL”=Return temperature probe has failed. “PrtrP”=Pre-trip is active. “C LIM”= Cool limit logic is active. “PULL”=Unit is in pulldown mode. |

Cd51 |

Automatic Cold Treatment (ACT) Mode Parameter Selection |

Code Cd51 initially displays countdown timer increments of 1 day, 1 hour with the temperature default. Pressing ENTER allows selection of within the current menu and proceeds to the next menu. After five seconds of no activity, the display reverts to normal system display, but retains the parameters previously selected. “ACt” = “On,” “Off” or “----”. The default is Off. “trEAt”=C /F in 0.1 degree increments. The default is 0.0°C. “DAyS”= “0-99” increments of 1. The default is 0. “ProbE”=probe positions (example 12°4). The default is ----. “SPnEW”= C /F in 0.1 degree increments. The default is 10.0°C. |

Cd53 |

Automatic Setpoint Change (ASC) Mode Parameter Selection |

Code Cd53 initially displays countdown timer increments of 1 day, 1 hour with the temperature default. Pressing ENTER allows selection of within the current menu and proceeds to the next menu. After five seconds of no activity, the display reverts to normal system display, but retains the parameters previously selected. “ASC”=”On” or “Off” The default is Off. “NSC”=”1-2” “SP 0"=C /F in 0.1 degree increments. The default is 10.0°C. “DAY 0"= “0-99” increments of 1. The default is 1. “SP 1"=C /F in 0.1 degree increments. The default is 10.0°C. “DAY 1"= “0-99” increments of 1. The default is 1. “SP 2"=C /F in 0.1 degree increments. The default is 10.0°C. |

Cd54 |

Suction Port Superheat / Electronic Expansion Valve Status |

Reading for evaporator superheat is shown on the right display. Press ENTER at Cd54 to show reading for EEV position (in%) on left display. |

Cd55 |

Discharge Superheat |

Code Cd55 will display the discharge superheat values in C /F as calculated by the discharge temperature minus the discharge saturation temperature as calculated from discharge pressure. “-----” will be displayed if selection is not valid. |

Cd58 |

Water Pressure Switch / Condenser Fan Switch State or Override Logic State |

Code Cd58 will display “CLOSE” if the WPS or CFS switch contacts are closed or that these options are not installed. “OPEn” is displayed when the WPS or CFS switch contacts are open. When the WPS/CFS Override Logic is “TRUE”, the right display will flash on all units. |

Cd59 |

Pump Down Logic |

Code Cd59 allows operation of the pump down logic control. The display will flash between “STArT PdN” and “PrESS EnTEr”. Once the operator confirms continuation of the sequence, pump down logic begins. If pump down logic is completed within 20 minutes, the unit will turn off and the display will flash “P dN DOnE” and “SHUT OFF”. The operator must shut off the unit. If the pump down logic is not completed within 20 minutes, the unit will return to its previous control condition. |

Cd60 |

Evaporator Fan Pulsing Temperature Setting |

CD60 contains a selectable temperature range used to determine the engagement point of the Evaporator Fan Pulsing logic. Default setting is -18.1°C. The user may change the temperature by pressing enter, then scrolling to the desired temperature using either arrow key. Press Enter to accept the change. The temperature setting will be retained until either a Pretrip or Trip Start is initiated at which time the temperature will set to the default setting. |

Cd62 |

High Speed Evaporator Fan Setting |

Cd62 is used to force evaporator fan speed to high while temperature control is being performed in the perishable setpoint range. When set to “On”, evaporator fans operate in high speed regardless of any other active option that can control evaporator fan speed. Following a power cycle, the state of the function select code is retained at its state prior to the power cycle. If “On”, this function select code will be set to “OFF” when any trip start occurs or any pre-trip test is initiated. “-----” will be displayed if setpoint is in frozen range or if CnF66 is configured OFF. |

Cd63 |

FuelWise |

Cd63 is used to enable FuelWise. Following a power cycle, the state of the function select code is retained at its state prior to the power cycle if CNF72 = Default ON else if Default OFF this will be set to OFF. If “On”, this function select code will be set to “OFF” when any trip start occurs or any pretrip test is initiated. Event 120 shall be logged when ever CD63 is Turned ON OR if CD63 state is ON at Midnight. “-----” will be displayed if Cnf72 is configured OFF. |

Cd65 |

TripWise |

If the function is off, display "OFF". If the function is on, display "ON". “-----” will be displayed if the TripWise option is not active for the current configuration. Press the ENTER key. The existing entry will flash. Use the Arrow keys to alternate between OFF and ON. Press ENTER again to set the Expiration Interval. Left display: “dAyS” Right display: Expiration Interval 2 through 365 in one day increments. Default value is 30. |

Cd66 |

Instantaneous Power (kW) |

Real power in kW currently being used by the system. Value is “-----“,“ nnn.n Display “-----“ if not configured else nnn.n |

Cd67 |

Total Power (kW-hr) |

Energy used by the system, in kW-hrs, since last Trip Start. Value is “-----“,“ nnnnn Display “-----“ if not configured else nnnnn |

Cd70 |

Temp Setpoint Lock |

Cd70 locks out setpoint selection, requiring the user to manually turn the lock off, prior to making a setpoint change. If the setpoint lock is “ON”, and the user attempts to enter a new setpoint, a message “SPLK” (Setpoint Lock) is in the left display and “ON” in the right display for five seconds. Press the ENTER key. “SPLK” will display along with the current setting of “ON” or “OFF”. Use the Arrow keys to change the selection - the new selection will then flash for five seconds. Press the ENTER key to confirm the new selection. An event will be recorded in the DataCorder each time the action of turning it “ON” or “OFF” is taken. Default setting is “OFF”. Unit will default to “OFF” with the selection of PTI or a TripWise on the unit. |

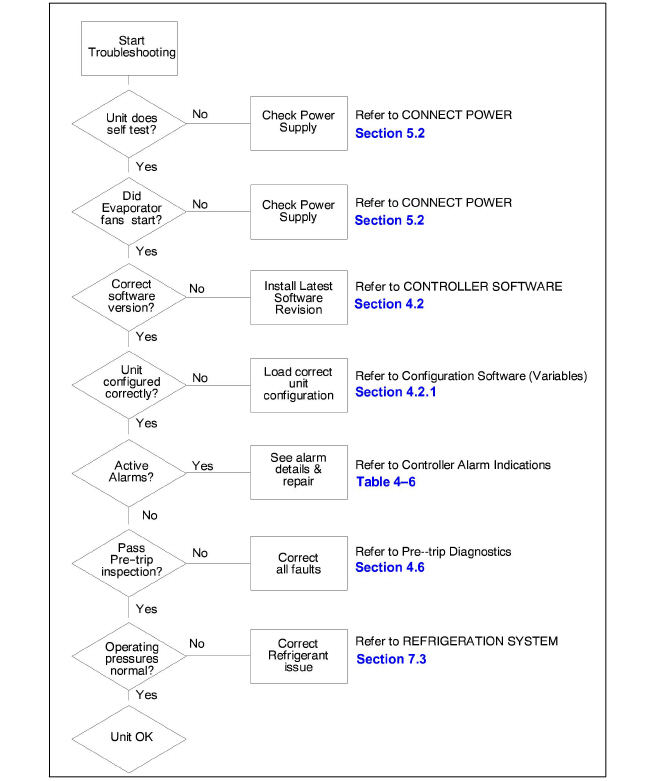

Figure 4.13 Alarm Troubleshooting Sequence

Code |

Cause |

Components |

Troubleshooting |

Corrective Actions |

|---|---|---|---|---|

AL03 Loss of Superheat Control |

Superheat has remained below 1.66°C (3°F) degrees for five minutes continuously while compressor running. Compressor drawing more than 2.0 amps, compressor pressure ratio is greater than 1.8, and Electronic Expansion Valve (EEV) is at 0% open. |

Electronic Expansion Valve (EEV) |

Check the operation of the EEV using Cd41. |

Replace EEV if defective. |

Evaporator Temperature Sensor(s) ETS & ETS1. |