Section 7

Use a refrigerant recovery system whenever removing refrigerant.When working with refrigerants you must comply with all local government environmental laws. In the U.S.A., refer to EPA section 608.

EXPLOSION HAZARD: Failure to follow this WARNING can result in death, serious personal injury and / or property damage. Never use air or gas mixtures containing oxygen (O2) for leak testing or operating the product. Charge only with R-134a: Refrigerant must conform to AHRI Standard 700 specification.

Annual maintenance procedures for PrimeLINE units 69NT40-561 can be found in the 62-10327 Annual Maintenance Manual, located in the Literature section of the Container Refrigeration website. To find the manual from the Literature section, click on Container Units > All Container Units > Operation.

Service procedures are provided herein beginning with refrigeration system service, then refrigeration system component service, electrical system service, temperature recorder service and general service. Refer to the Table of Contents to locate specific topics.

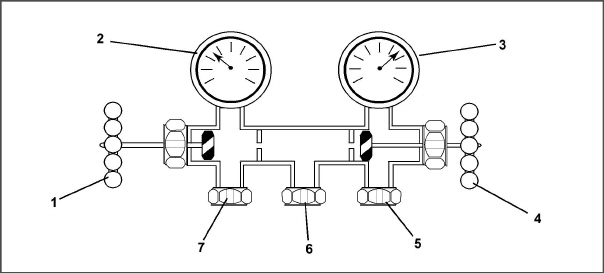

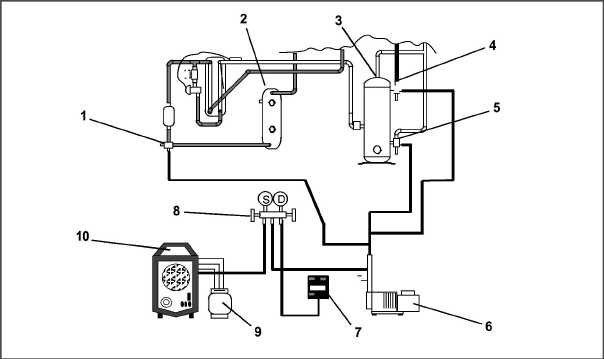

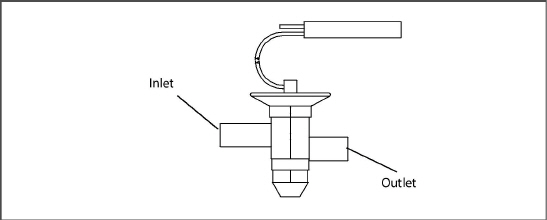

The manifold gauge set (see Figure 7.1) is used to determine system operating pressure, add refrigerant charge, and to equalize or evacuate the system.

1)Discharge Pressure Valve (shown backseated)

2)Discharge Pressure Gauge

3)Suction Pressure Gauge

4)Suction Pressure Valve (shown frontseated)

5)Low Side Connection

6)Utility

Connection to:

a. Refrigerant Cylinder

b. Vacuum Pump

c. Oil Container

7)High Side Connection

- - - - -

When the Suction Pressure Valve is frontseated (turned all the way in), the suction (low) pressure can be checked at the Suction Pressure Gauge.

When the Discharge Pressure Valve is frontseated, the discharge (high) pressure can be checked at the Discharge Pressure Gauge.

When both valves are backseated (all the way out), high pressure vapor will flow into the low side.

When the Suction Pressure Valve is open and the Discharge Pressure Valve shut, the system can be charged through the Utility Connection. Oil can also be added to the system.

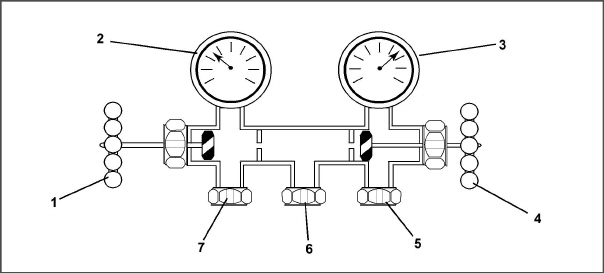

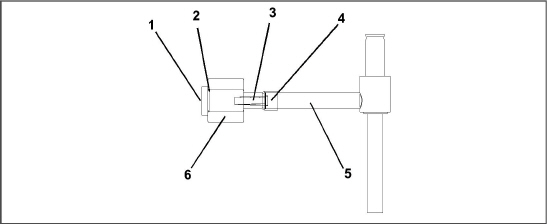

A R-134a manifold gauge/hose set with self-sealing hoses (see Figure 7.2) is required for service of the models covered within this manual. The manifold gauge/hose set is available from Carrier Transicold. (Carrier Transicold part number 07-00294-00, which includes items 1 through 6, Figure 7.2.)

If the manifold gauge/hose set is new or was exposed to the atmosphere, it will need to be evacuated to remove contaminants and air as follows:

1.Backseat (turn counterclockwise) both field service couplings (see Figure 7.2) and midseat both hand valves.

2.Connect the yellow hose to a vacuum pump and refrigerant 134a cylinder.

Figure 7.2 R-134a Manifold Gauge/Hose Set

1)RED Refrigeration and/or Evacuation Hose (SAE J2196/R-134a)

3)YELLOW Refrigeration and / or Evacuation Hose (SAE J2196/R-134a)

4)Hose Fitting with O-ring (M14 x 1.5)

5)High Side Field Service Coupling (Red Knob)

6)BLUE Refrigeration and / or Evacuation Hose (SAE J2196/R-134a)

7)Low Side Field Service Coupling (Blue Knob)

- - - - -

3.Evacuate to 10 inches of vacuum and then charge with R-134a to a slightly positive pressure of 0.1 kg/ cm2 (1.0 psig).

4.Frontseat both manifold gauge set valves and disconnect from cylinder. The gauge set is now ready for use.

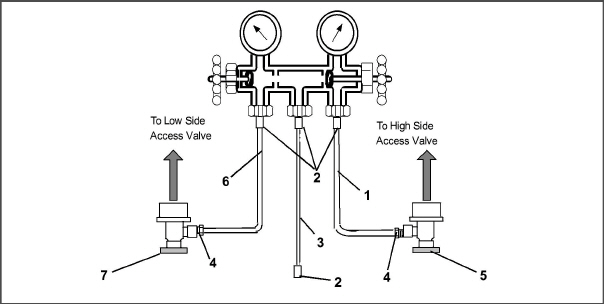

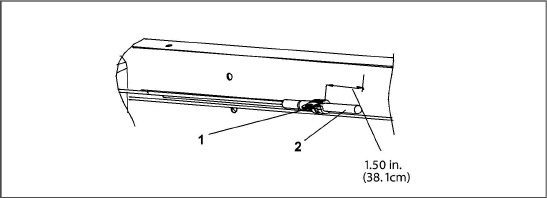

The compressor suction, compressor discharge, and the liquid line service valves (see Figure 7.3) are provided with a double seat and an access valve which enables servicing of the compressor and refrigerant lines.

Turning the valve stem clockwise (all the way forward) will frontseat the valve to close off the line connection and open a path to the access valve. Turning the stem counterclockwise (all the way out) will backseat the valve to open the line connection and close off the path to the access valve.

With the valve stem midway between frontseat and backseat, both of the service valve connections are open to the access valve path.

For example, the valve stem is first fully backseated when connecting a manifold gauge to measure pressure. Then, the valve is opened 1/4 to 1/2 turn to measure the pressure.

5)Compressor Or Filter Drier Inlet Connection

- - - - -

Connection of the manifold gauge/hose set (see Figure 7.4) is dependent on the component being serviced. If only the compressor is being serviced, the high side coupling is connected to the discharge service valve.

For service of the low side (after pump down), the high side coupling is connected to the liquid line service valve. The center hose connection is brought to the tool being used (vacuum, tank, etc.).

7.3.1Connecting the Manifold Gauge Set

1.Remove service valve stem cap and to make sure the valve is backseated.

2.Remove access valve cap (see Figure 7.3).

3.Connect the field service coupling (see Figure 7.2) to the access valve.

4.Turn the field service coupling knob clockwise, which will open the system to the gauge set.

5.To read system pressures, slightly midseat the service valve.

6.Repeat the procedure to connect the other side of the gauge set.

To prevent trapping liquid refrigerant in the manifold gauge set be sure set is brought to suction pressure before disconnecting.

7.3.2Removing the Manifold Gauge Set:

1.While the compressor is still ON, backseat the high side service valve.

2.Midseat both hand valves on the manifold gauge set and allow the pressure in the manifold gauge set to be drawn down to low side pressure. This returns any liquid that may be in the high side hose to the system.

3.Backseat the low side service valve. Backseat both field service couplings and frontseat both manifold hand valves. Remove couplings from access valves.

4.Install both service valve stem caps and service port caps (finger-tight only).

To service the filter drier, economizer, expansion valves, economizer solenoid valve, digital unloader valve or evaporator coil, pump the refrigerant into the high side as follows:

The scroll compressor achieves low suction pressure very quickly. Do not use the compressor to evacuate the system below 0 psig. Never operate the compressor with the suction or discharge service valves closed (frontseated). Internal damage will result from operating the compressor in a deep vacuum.

1.Attach manifold gauge set to the compressor suction and discharge service valves (see Section 7.2).

2.Start the unit and run in the frozen mode (controller set below -10°C (14°F) for 10 to 15 minutes.

3.Check function code Cd21 (see Section 4.2.2). The economizer solenoid valve should be open. If not, continue to run until the valve opens.

4.Frontseat the liquid line service valve. Place Start-Stop switch in the OFF position when the suction reaches a positive pressure of 0.1 bar (1.4 psig).

5.Frontseat the suction and discharge service valves. The refrigerant will be trapped between the compressor discharge service valves and the liquid line valve.

6.Before opening up any part of the system, a slight positive pressure should be indicated on the pressure gauge. Remove power from the unit before opening any part of the system. If a vacuum is indicated, emit refrigerant by cracking the liquid line valve momentarily to build up a slight positive pressure.

7.When opening up the refrigerant system, certain parts may frost. Allow the part to warm to ambient temperature before dismantling. This avoids internal condensation which puts moisture in the system.

8.After repairs have been made, be sure to perform a refrigerant leak check (see Section 7.5), and evacuate and dehydrate the low side (see Section 7.6.1).

9.Check refrigerant charge (see Section 7.7.1).

EXPLOSION HAZARD Failure to follow

this WARNING can result in death, serious personal injury and / or property

damage.

Never use air or gas mixtures containing oxygen (O2) for leak

testing or operating the product.

Charge only with R-134a: Refrigerant must conform to AHRI Standard 700

specification.

1.The recommended procedure for finding leaks in a system is with a R-134a electronic leak detector. Testing joints with soapsuds is satisfactory only for locating large leaks.

2.If the system is without refrigerant, charge the system with refrigerant 134a to build up pressure between2.1 to 3.5 bar (30.5 to 50.8 psig). To ensure complete pressurization of the system, refrigerant should be charged at the compressor suction valve and the liquid line service valve. Remove refrigerant cylinder and leak-check all connections.

Only refrigerant 134a should be used to pressurize the system. Any other gas or vapor will contaminate the system, which will require additional purging and evacuation of the system.

3.If required, remove refrigerant using a refrigerant recovery system and repair any leaks. Check for leaks.

4.Evacuate and dehydrate the unit (see Section 7.6.1.)

5.Charge unit (see Section 7.7.1).

Moisture is detrimental to refrigeration systems. The presence of moisture in a refrigeration system can have many undesirable effects. The most common are copper plating, acid sludge formation, “freezing-up” of metering devices by free water, and formation of acids, resulting in metal corrosion.

1.Evacuate and dehydrate only after pressure leak test (see Section 7.5).

2.Essential tools to properly evacuate and dehydrate any system include a vacuum pump (8m3/hr = 5 cfm volume displacement) and an electronic vacuum gauge. The pump is available from Carrier Transicold, P/N 07-00176-11. The micron gauge is P/N 07- 00414- 00.

3.If possible, keep the ambient temperature above 15.6°C (60°F) to speed evaporation of moisture. If the ambient temperature is lower than 15.6°C (60°F), ice might form before moisture removal is complete. Heat lamps or alternate sources of heat may be used to raise the system temperature.

4.Additional time may be saved during a complete system pump down by replacing the filter drier with a section of copper tubing and the appropriate fittings. Installation of a new drier may be performed during the charging procedure.

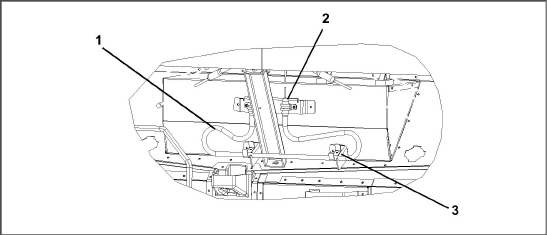

Figure 7.4 Refrigeration System Service Connections

2)Receiver or Water Cooled Condenser

4)Discharge Service Connection

- - - - -

7.6.3Evacuate and Dehydrate - Complete System

Refer to Partial System procedure for information pertaining to partial system evacuation and dehydration.

1.Remove all refrigerant using a refrigerant recovery system.

2.The recommended method to evacuate and dehydrate the system is to connect evacuation hoses at the compressor suction and liquid line service valve (see Figure 7.4). Be sure the service hoses are suited for evacuation purposes.

3.Test the evacuation setup for leaks by backseating the unit service valves and drawing a deep vacuum with the vacuum pump and gauge valves open. Shut off the pump and check to see if the vacuum holds. Repair leaks if necessary.

4.Midseat the refrigerant system service valves.

5.Open the vacuum pump and electronic vacuum gauge valves, if they are not already open. Start the vacuum pump. Evacuate unit until the electronic vacuum gauge indicates 2000 microns. Close the electronic vacuum gauge and vacuum pump valves. Shut off the vacuum pump. Wait a few minutes to be sure the vacuum holds.

6.Break the vacuum with either clean dry refrigerant 134a or dry nitrogen. Raise system pressure to roughly 0.14 bar (2 psig), monitoring it with the compound gauge.

7.Remove refrigerant using a refrigerant recovery system.

8.Repeat steps e. and f. one time.

9.Remove the copper tubing and change the filter drier. Evacuate unit to 500 microns. Close the electronic vacuum gauge and vacuum pump valves. Shut off the vacuum pump. Wait five minutes to see if vacuum holds. This procedure checks for residual moisture and/or leaks.

10.With a vacuum still in the unit, the refrigerant charge may be drawn into the system from a refrigerant container on weight scales.

7.6.4Evacuate and Dehydrate - Partial System

1.If refrigerant charge has been removed from the low side only, evacuate the low side by connecting the evacuation set-up at the compressor suction valve and the liquid service valve but leave the service valves frontseated until evacuation is completed.

2.Once evacuation has been completed and the pump has been isolated, fully backseat the service valves to isolate the service connections and then continue with checking and, if required, adding refrigerant in accordance with normal procedures.

EXPLOSION HAZARD Failure to follow this WARNING can result in death, serious personal injury and / or property damage. Never use air or gases containing oxygen (O2) for leak testing or operating the product. Charge only with R- 134a: Refrigerant must conform to AHRI Standard 700 specification.

7.7.1Checking the Refrigerant Charge

Use a refrigerant recovery system whenever removing refrigerant.When working with refrigerants you must comply with all local government environmental laws. In the U.S.A., refer to EPA Section 608.

1.Connect the gauge manifold to the compressor discharge and suction service valves. For units operating on a water cooled condenser, change over to air cooled operation.

2.Bring the container temperature to approximately 0°C (32°F) or below. Then set the controller set point to -25°C (-13°F).

3.Partially block the condenser coil inlet air. Increase the area blocked until the compressor discharge pressure is raised to approximately 12.8 bar (185 psig).

4.On units equipped with a receiver, the level should be between the glasses. On units equipped with a water-cooled condenser, the level should be at the center of the glass. If the refrigerant level is not correct, continue with the following paragraphs to add or remove refrigerant as required.

7.7.2Adding Refrigerant to System (Full Charge)

1.Evacuate unit and leave in deep vacuum (see Section 7.6.1).

2.Place cylinder of R-134a on scale and connect charging line from cylinder to liquid line valve. Purge charging line at liquid line valve and then note weight of cylinder and refrigerant.

3.Open liquid valve on cylinder. Open liquid line valve half-way and allow liquid refrigerant to flow into the unit until the correct weight of refrigerant (see Section 3.2) has been added as indicated by scales.

It may be necessary to finish charging unit through suction service valve in gas form, due to pressure rise in high side of the system.

4.Backseat manual liquid line valve (to close off gauge port). Close liquid valve on cylinder.

5.Start unit in cooling mode. Run for approximately 10 minutes and check the refrigerant charge.

7.7.3Adding Refrigerant to System (Partial Charge)

1.Examine refrigerant system for any evidence of leaks, repair as necessary (see Section 7.5).

2.Maintain the conditions outlined in Section 7.7.1.

3.Fully backseat the suction service valve and remove the service port cap.

4.Connect charging line between suction service valve port and cylinder of refrigerant R-134a. Open VAPOR valve.

5.Partially frontseat (turn clockwise) the suction service valve and slowly add charge until the refrigerant appears at the proper level. Be careful not to frontseat the suction valve fully, if the compressor is operated in a vacuum, internal damage may result.

Make sure power to the unit is OFF and power plug disconnected before replacing the compressor.

Before disassembly of the compressor, be sure to relieve the internal pressure very carefully by slightly loosening the couplings to break the seal.

The scroll compressor achieves low suction pressure very quickly. Do not use the compressor to evacuate the system below 0 psig. Never operate the compressor with the suction or discharge service valves closed (frontseated). Internal damage will result from operating the compressor in a deep vacuum.

The PrimeLINE unit has a hermetically sealed compressor that should not be opened and/or repaired. Doing so can cause a loss in performance and premature system failure due to the precision machinery and assembly required within the compressor. To repair the unit, remove the faulty compressor and replace with an approved Carrier compressor. If the return of the compressor is not required, follow local waste collection & recycling regulations in discarding the compressor.

Replacement compressors are supplied without oil.

7.8.1Removal and Replacement of Compressor

1.Turn the unit ON and run it in full cool mode for 10 minutes.

If the compressor is not operational, front-seat the suction and discharge service valves and go to step e. below.

2.Frontseat the manual liquid line valve and allow the unit to pull-down to 0.1 kg/cm2 (1 psig).

3.Turn the unit start-stop switch (ST) and unit circuit breaker (CB-1) OFF, and disconnect power to the unit.

4.Frontseat the discharge and suction service valves.

5.Remove all remaining refrigerant from the compressor using a refrigerant recovery system.

6.Remove the compressor terminal cover, disconnect the ground wire and pull the cable plug from the compressor terminals. Install the terminal cover back after removing the power cable.

Inspect the power cable (plug) terminals to ensure they are not deformed or have any signs of heat or arcing. If any damage is noted, replace the power cable.

7.Remove the Rotalock fittings from the suction and discharge service connections, and uncouple the unloader and economizer lines from the compressor.

8.Cut the dome temperature sensor (CPDS) wires. The replacement compressor comes with a CPDS already assembled.

9.Remove and save the compressor base mounting bolts. Discard the 4 top resilient mounts and washers.

10.Remove (slide out) the old compressor from the unit.

11.Inspect compressor base plate for wear. Replace, if necessary.

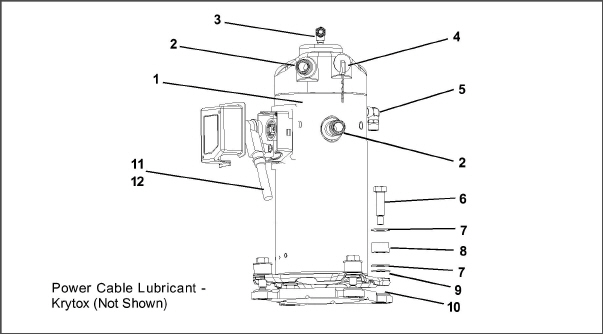

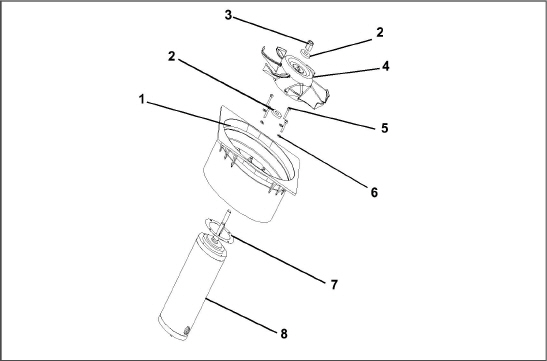

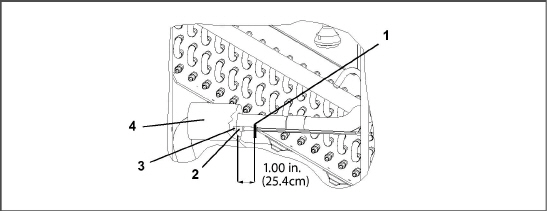

12.Wire tie the compressor base plate to the compressor, and then slide the new compressor into the unit (see Figure 7.5).

2)Teflon Seal for Valve Connection (2)

3)O-Ring (Unloader Connection)

4)Compressor Discharge Temperature Sensor

5)O-Ring (Economizer Connection)

- - - - -

DO NOT add any oil to the replacement compressor. Replacement compressor is shipped with full oil charge of 60 oz.

13.Cut and discard the wire ties used to hold the base plate to the compressor.

14.Place the new SST washers on each side of the resilient mounts, and the new Mylar washer on the bottom of it (see Figure 7.5). Install the four base mounting bolts loosely.

15.Place the new Teflon seals at the compressor suction and discharge ports as well as the O-rings at the unloader and economizer line connection ports. Hand tighten all four connections.

16.Torque the four base-mounting screws to 6.2 mkg (45 ft- lbs).

17.Torque the compressor ports / connections to:

Service Valve / Connection |

Torque Value |

|---|---|

Suction and Discharge Rotalocks |

108.5 to 135.5 Nm (80 to 100 ft-lbs.) |

Unloader connection |

24.5 to 27 Nm (18 to 20 ft-lbs.) |

Economized connection |

32.5 to 35 Nm (24 to 26 ft-lbs.) |

18.Connect (butt-splice and heat shrink) the new compressor dome temperature sensor with the old sensor wires removed in step h. Wire-tie any loose wiring as appropriate.

19.Evacuate the compressor to 1000microns if the unit was pumped down before the replaced compressor was removed. Otherwise, evacuate the complete unit and charge it with R-134a refrigerant (see Section 7.6.1 and Section 7.7.1).

20.Open the compressor terminal cover and connect the compressor power cable following the steps below:

a.Liberally coat the orange gasket surfaces with the Krytox lubricant.

b.Install the orange gasket part onto the compressor fusite with the grooved or threaded side out. Ensure that the gasket is seated onto the fusite base.

c.Coat the inside of the power plug (female) connector pins with the Krytox lubricant, and insert the plug onto the compressor terminal connections. Make sure the orange gasket has bottomed out onto the fusite and it fits securely onto the terminal pins while fully inserted into the orange plug.

d.Connect the green ground wire to the grounding tab located inside the terminal box of the compressor using the self-tapping grounding screw. Close the compressor terminal box using the terminal cover removed in step t.

21.Backseat all service valves, connect the power to the unit and run it for at least 20 minutes.

22.Perform a leak check of the system.

7.9.1Checking High Pressure Switch

Do not use a nitrogen cylinder without a pressure regulator.

The high pressure switch is non-adjustable.

1.Remove the switch (see Section 7.9.2).

2.Connect ohmmeter or continuity light across switch terminals. Ohmmeter will indicate no resistance or continuity light will be illuminated if the switch closed after relieving compressor pressure.

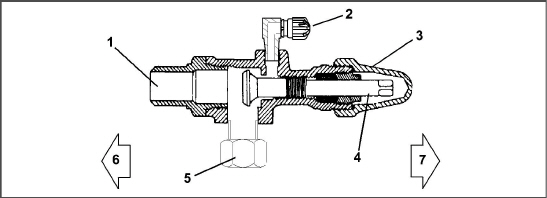

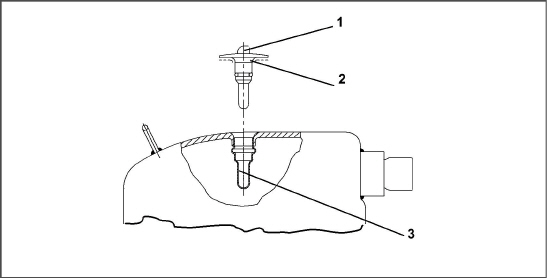

3.Connect hose to a cylinder of dry nitrogen (see Figure 7.6).

Figure 7.6 High Pressure Switch Testing

4)Pressure Gauge (0 to 36 kg/cm2 = 0 to 400 psig)

- - - - -

4.Set nitrogen pressure regulator at 26.4 kg/cm2 (375 psig) with bleed-off valve closed.

5.Close valve on cylinder and open bleed-off valve.

6.Open cylinder valve. Slowly close bleed-off valve to increase pressure on switch. The switch should open at a static pressure up to 25 kg/cm2 (350 psig). If a light is used, the light will go out. If an ohmmeter is used, the meter will indicate open circuit.

7.Slowly open bleed-off valve to decrease the pressure. The switch should close at 18 kg/cm2 (250 psig).

7.9.2Replacing High Pressure Switch

1.Remove the refrigerant charge.

2.Disconnect wiring from defective switch. The high pressure switch is located on the discharge connection or line and is removed by turning counterclockwise.

3.Install a new high pressure switch after verifying switch settings.

4.Evacuate, dehydrate and recharge the system.

5.Start the unit, verify refrigeration charge and oil level.

The condenser coil consists of a series of parallel copper tubes expanded into copper fins. The condenser coil must be cleaned with fresh water or steam so the air flow is not restricted. To replace the coil, do the following:

Do not open the condenser fan grille before turning power OFF and disconnecting the power plug.

1.Using a refrigerant reclaim system, remove the refrigerant charge.

2.Remove the condenser coil guard.

3.Unsolder the lines and remove the line to the receiver or water-cooled condenser.

4.Remove the coil mounting hardware and remove the coil from the unit.

5.Install the replacement coil and solder connections.

6.Leak-check the coil connections (see Section 7.5).

7.Evacuate the unit then charge the unit with refrigerant.

7.11Condenser Fan and Motor Assembly

Do not open the condenser fan grille before turning power OFF and disconnecting the power plug.

The condenser fan rotates counter-clockwise (viewed from front of unit), pulls air through the condenser coil, and discharges horizontally through the front of the unit.

To replace the condenser fan motor assembly:

1.Open condenser fan screen guard.

2.Loosen two square head set screws on fan. (Thread sealer has been applied to set screws at installation.)

3.Disconnect wiring connector.

Take necessary steps (place plywood over coil or use sling on motor) to prevent motor from falling into condenser coil.

4.Remove motor mounting hardware and replace the motor. It is recommended that new locknuts be used when replacing motor.

5.Connect the wiring connector.

6.Install fan loosely on motor shaft (hub side in). DO NOT USE FORCE. If necessary, tap the hub only, not the hub nuts or bolts. Install venturi. Apply “Loctite H” to fan set screws. Adjust fan within venturi so that the outer edge of the fan is within 2.0 +/- 0.07 mm (0.08” +/- 0.03”) from the outside of the orifice opening. Spin fan by hand to check clearance.

7.Close and secure condenser fan screen guard.

7.12Water-Cooled Condenser Cleaning

The water-cooled condenser is of the shell and coil type with water circulating through the cupro-nickel coil. The refrigerant vapor is admitted to the shell side and is condensed on the outer surface of the coil.

Rust, scale and slime on the water-cooling surfaces inside of the coil interfere with the transfer of heat, reduce system capacity, cause higher head pressures and increase the load on the system.

By checking the leaving water temperature and the actual condensing temperature, it can be determined if the condenser coil is becoming dirty. A larger than normal difference between leaving condensing water temperature and actual condensing temperature, coupled with a small difference in temperature of entering and leaving condensing water, is an indication of a dirty condensing coil.

To find the approximate condensing temperature, with the unit running in the cooling mode, install a gauge 0 to 36.2 kg/cm2 (0 to 500 psig) on the compressor discharge service valve.

Example: Discharge pressure is 10.3 kg/cm2 (146.4 psig). See Table 7–5 (R-134a pressure/ temperature chart), the 10.3 kg/cm2 (146.4 psig) value converts to 43°C (110°F).

If the water-cooled condenser is dirty, it may be cleaned and de-scaled by the following procedure:

1.Turn unit off and disconnect main power.

2.Disconnect water pressure switch tubing by loosening the two flare nuts. Install one-quarter inch flare cap on water-cooled condenser inlet tube (replaces tubing flare nut). De-scale tubing if necessary.

What You Will Need:

•Oakite Aluminum Cleaner® 164, available as a powder in 20 kg (44 lb) pails and 205 kg (450 lb) drums.

•Oakite Composition No. 32, available as a liquid in cases, each containing 3.785 liters (4 U.S. gallon) bottles and also in carboys of 52.6 kg (116 lbs) net.

•Fresh clean water.

•Acid proof pump and containers or bottles with rubber hose.

When Oakite Compound No. 32 is used for the first time, the local Oakite Technical Service representative should be called in for suggestions in planning the procedure. The representative will advise the reader on how to do the work with a minimum dismantling of equipment: how to estimate the time and amount of compound required; how to prepare the solution; how to control and conclude the de-scaling operation by rinsing and neutralizing equipment before putting it back into service. The representative’s knowledge of metals, types of scale, water conditions and de-scaling techniques will be highly useful.

Summary of Procedure:

1.Drain water from condenser tubing circuit.

2.Clean water tubes with Oakite Aluminum Cleaner) 164 to remove mud and slime.

3.Flush.

4.De-scale water tubes with Oakite No. 32 to remove scale.

5.Flush.

6.Neutralize.

7.Flush.

8.Put unit back in service under normal load and check head (discharge) pressure.

Detailed Procedure:

1.Drain and flush the water circuit of the condenser coil. If scale on the tube inner surfaces is accompanied by slime, a thorough cleaning is necessary before de-scaling process can be accomplished.

2.To remove slime or mud, use Aluminum Cleaner® 164. Mixed 170 grams (6 ounces) per 3.785 liters (1 U.S. gallon) of water. Mix cleaner in one half the volume of water, while stirring, and then add remaining water. Warm this solution and circulate through the tubes until all slime and mud has been removed.

3.After cleaning, flush tubes thoroughly with fresh clean water.

4.Prepare a 15% by volume solution for de-scaling, by diluting Oakite Compound No. 32 with water. This is accomplished by slowly adding 0.47 liter (1 U.S. pint) of the acid (Oakite No. 32) to 2.8 liters (3 U.S. quarts) of water.

Oakite No. 32 is an acid. Be sure that the acid is slowly added to the water. DO NOT PUT WATER INTO THE ACID - this will cause spattering and excessive heat.

Wear rubber gloves and wash the solution from the skin immediately if accidental contact occurs. Do not allow the solution to splash onto concrete.

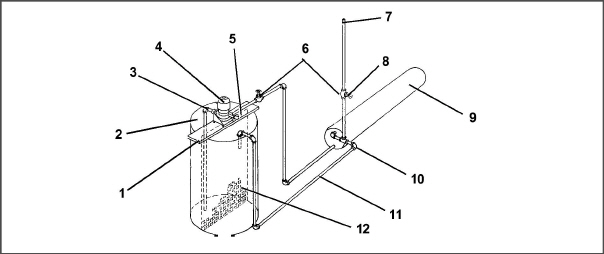

5.Fill the tubes with this solution by filling from the bottom (see Figure 7.7).

Figure 7.7 Water-Cooled Condenser Cleaning, Forced Circulation

5)Priming Connection (Centrifugal pump 50 gpm at 35’ head)

8)Close vent pipe valve when pump is running

10)Remove water regulating valve

- - - - -

It is important to provide a vent at the top for escaping gas.

6.Allow the Oakite No. 32 solution to soak in the tube coils for several hours, periodically pump-circulating it with an acid-proof pump.

An alternate method may be used whereby a pail (see Figure 7.8) filled with the solution and attached to the coils by a hose can serve the same purpose by filling and draining. The solution must contact the scale at every point for thorough de-scaling. Air pockets in the solution should be avoided by regularly opening the vent to release gas. Keep flames away from the vent gases.

7.The time required for de-scaling will vary, depending upon the extent of the deposits. One way to determine when de-scaling has been completed is to titrate the solution periodically, using titrating equipment provided free by the Oakite Technical Service representative. As scale is being dissolved, titrate readings will indicate that the Oakite No. 32 solution is losing strength. When the reading remains constant for a reasonable time, this is an indication that scale has been dissolved.

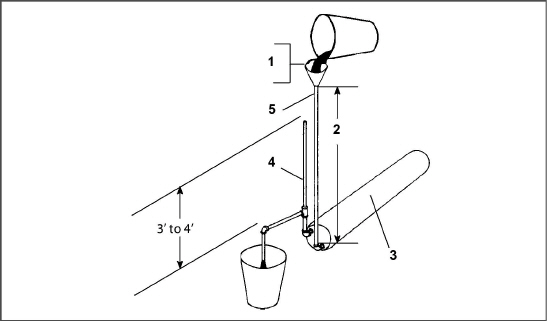

Figure 7.8 Water-Cooled Condenser Cleaning - Gravity Circulation

1)Fill condenser with cleaning solution. Do not add solution more rapidly than vent can exhaust gases caused by chemical action.

- - - - -

8.When de-scaling is complete, drain the solution and flush thoroughly with water.

If condenser cooling water is not being used as drinking water or is not re-circulated in a closed or tower system, neutralizing is not necessary.

9.Following the water flush, circulate a 56.7 gram (2 ounce) per 3.785 liter (1 U.S. gallon) solution of Oakite Aluminum Cleaner® 164 thru the tubes to neutralize. Drain this solution.

10.Flush the tubes thoroughly with fresh water.

11.Put the unit back in service and operate under normal load. Check the head pressure. If normal, a thorough de-scaling has been achieved.

What You Can Do For Further Help:

Contact the Engineering and Service Department of the OAKITE PRODUCTS CO., 675 Central Avenue, New Providence, NJ 07974 U.S.A. (or visit www.oakite.com) for the name and address of the service representative in your area.

On units equipped with a water-cooled condenser, if the sight glass appears to be flashing or bubbles are constantly moving through the sight glass, the unit may have a low refrigerant charge or the filter drier could be partially plugged.

7.13.1Checking the Filter Drier

1.Test for a restricted or plugged filter drier by feeling the liquid line inlet and outlet connections of the drier cartridge. If the outlet side feels cooler than the inlet side, then the filter drier should be changed.

2.Check the moisture-liquid indicator. If the indicator shows a high level of moisture, the filter drier should be replaced.

7.13.2Replacing the Filter Drier

1.Pump down the unit (see Section 7.4). Evacuate if unit is not equipped with service valves. Then replace filter drier.

2.Evacuate the low side (see Section 7.6).

3.After unit is in operation, inspect for moisture in system and check charge.

7.14Evaporator Coil & Heater Assembly

The evaporator section, including the evaporator coil, should be cleaned regularly. The preferred cleaning fluid is fresh water or steam. Another recommended cleaner is Oakite 202 or similar, following manufacturer’s instructions.

The two drain pan hoses are routed behind the condenser fan motor and compressor. The drain pan line(s) must be open to ensure adequate drainage.

7.14.1Evaporator Coil Replacement

1.Pump the unit down (see Section 7.4). Evacuate if unit is not equipped with service valves (see Section 7.6.1).

2.With power OFF and power plug removed, remove the screws securing the panel covering the evaporator section (upper panel).

3.Disconnect the defrost heater wiring.

4.Remove the mounting hardware from the coil.

5.Unsolder the two coil connections, one at the distributor and the other at the coil header.

6.Disconnect the defrost temperature sensor (see Figure 3.2) from the coil.

7.Remove middle coil support.

8.After defective coil is removed from unit, remove defrost heaters and install on replacement coil.

9.Install coil assembly by reversing above steps.

10.Leak check connections. Evacuate and add refrigerant charge.

7.14.2Evaporator Heater Replacement

The heaters are wired directly back to the contactor and if a heater failure occurs during a trip, the heater set containing that heater may be disconnected at the contactor.

The next Pre-trip (P1) will detect that a heater set has been disconnected and indicate that the failed heater should be replaced. To remove a heater, do the following:

1.Before servicing unit, make sure the circuit breakers (CB-1 and CB-2) and start-stop switch (ST) are in the OFF position, and the power plug is disconnected.

2.Remove the upper back panel.

3.Determine which heater(s) need replacing by checking resistance of each heater set. See Section 3.3 for heater resistance values. Once the set containing the failed heater is determined, cut the splice connection and retest to determine the actual failed heater(s).

4.Remove hold-down clamp securing heater(s) to coil.

5.Lift the bent end of the heater (with the opposite end down and away from coil). Move heater to the side enough to clear the heater end support and remove

To replace a heater, do steps a through e in reverse.

Optional 5+1 Heater Arrangement Heater Removal and Replacement

Complete steps a through e noted above, then remove straight and Omega heaters:

a. To remove straight heater:

1.Locate holding clips positioned at the ends of the heater element.

2.Rotate clips toward the center of the container unit.

3.Lift the heater slightly up and out to remove.

b. To remove Omega heater (see Figure 7.9):

1.Remove the two tube clamps located near the top of the heater element.

2.Locate the holding clips positioned at the bottom of the heater element and rotate slightly toward the center of the container unit.

3.Carefully pull heater out to remove.

Figure 7.9 5+1 Heater Arrangement - Omega Heater

1)Omega Heater

2)Tube Clamps (2)

3)Holding Clips (2)

- - - - -

7.15Evaporator Fan and Motor Assembly

The evaporator fans circulate air throughout the container by pulling air in the top of the unit. The air is forced through the evaporator coil where it is either heated or cooled and then discharged out the bottom of the refrigeration unit into the container. The fan motor bearings are factory lubricated and do not require additional grease.

7.15.1Replacing the Evaporator Fan Assembly

Always turn OFF the unit circuit breakers (CB-1 & CB-2) and disconnect main power supply before working on moving parts.

1.Remove access panel (see Figure 3.2) by removing mounting bolts and TIR locking device. Reach inside of unit and remove the Ty-Rap securing the wire harness loop. Disconnect the connector by twisting to unlock and pulling to separate.

2.Loosen four 1/4-20 clamp bolts that are located on the underside of the fan deck at the sides of the fan assembly. Slide the loosened clamps back from the fan assembly.

3.Slide the fan assembly out from the unit and place on a sturdy work surface.

7.15.2Disassemble the Evaporator Fan Assembly

1.Attach a spanner wrench to the two 1/4-20 holes located in the fan hub. Loosen the 5/8-18 shaft nut by holding the spanner wrench stationary and turning the 5/8-18 nut counter-clockwise (see Figure 7.10).

2.Remove the spanner wrench. Use a universal wheel puller and remove the fan from the shaft. Remove the washers and key.

3.Remove the four 1/4-20 x 3/4 long bolts that are located under the fan that support the motor and stator housing. Remove the motor and plastic spacer.

7.15.3Assemble the Evaporator Fan Assembly

1.Assemble the motor and plastic spacer onto the stator.

When removing the black nylon evaporator fan blade, care must be taken to assure that the blade is not damaged. In the past, it was a common practice to insert a screwdriver between the fan blades to keep it from turning. This practice can no longer be used, as the blade is made up of a material that will be damaged. It is recommended that an impact wrench be used when removing the blade. Do not use the impact wrench when reinstalling, as galling of the stainless steel shaft can occur.

2.Apply Loctite to the 1/4-20 x 3/4 long bolts and torque to 0.81 mkg (70 inch-pounds).

3.Place one 5/8 flat washer on the shoulder of the fan motor shaft. Insert the key in the keyway and lubricate the fan motor shaft and threads with a graphite-oil solution (such as Never-seez).

4.Install the fan onto the motor shaft. Place one 5/8 flat washer with a 5/8-18 locknut onto the motor shaft and torque to 40 foot-pounds.

Figure 7.10 Evaporator Fan Assembly

- - - - -

5.Install the evaporator fan assembly in reverse order of removal. Torque the four 1/4-20 clamp bolts to 0.81 mkg (70 inch-pounds). Connect the wiring connector.

6.Replace access panel, making sure that the panel does not leak. Make sure that the TIR locking device is lockwired.

7.16Evaporator Section Cleaning

Containers and Container units that are exposed to certain fumigants may develop visible surface corrosion. This corrosion will show up as a white powder found on the inside of the container and on the reefer unit evaporator stator and fan deck. Analyses by Carrier Transicold environmental specialists have identified the white powder as consisting predominantly of aluminum oxide. Aluminum oxide is a coarse crystalline deposit most likely the result of surface corrosion on the aluminum parts within the container. If left untreated over time, it may build up in thickness and eventually flake as a light-weight white powder.

The surface corrosion of aluminum is brought about by exposure to chemicals such as sulfur dioxide and possibly other fumigants that are commonly used for fumigation and protection of some perishable cargo such as grapes, for example. Fumigation is the process by which a chemical is released into an enclosed area to eliminate infestations of insects, termites, rodents, weeds and soil-born disease.

Typically any aluminum oxide that becomes detached from evaporator fan stators will be blown into the wet evaporator coil where it will be caught and then flushed out of the unit during routine defrost cycles.

However, it is still highly recommended that after carrying cargo subject to fumigation procedures, that the inside of the unit be thoroughly cleansed prior to reuse.

Carrier Transicold has identified a fully biodegradable and environmentally safe alkaline cleaning agent (Tri- Pow’r® HD) for the unit. This will assist in helping to remove the corrosive fumigation chemicals and dislodging of the corrosive elements.

This cleaner is available from the Carrier Transicold Performance Parts Group (PPG) and can be ordered through any of the PPG locations; Part Number NU4371-88.

As a general safety precaution, before using this product, refer to and retain the Material Safety Data (MSDS) sheet.

Prior to Cleaning:

•Always wear goggles, gloves and work boots.

•Avoid contact with skin and clothing, and avoid breathing mists.

•When mixing, add water to the sprayer first, then the cleaner.

•ALWAYS provide for proper ventilation when cleaning indoor evaporator coils (rear doors must be open).

•Be aware of surroundings - food, plants, etc., and the potential for human exposure.

•Always read directions and follow recommended dilution ratios. More is not always better. Using non-diluted cleaner is not recommended.

Cleaning Procedure:

1.Remove the upper evaporator access panel inside of the unit.

2.Spray the surface with water before applying the cleaning solution. This helps the cleaner work better.

3.Liberally apply the prepared cleaner solution (5 parts water and 1 part cleaner).

4.Allow the cleaner to soak in for 5 to 7 minutes.

5.Assess area for rinsing. Follow all local regulations regarding disposal of waste water.

6.Thoroughly rinse the cleaner and surrounding area, floor, etc.When rinsing where heavy foaming solution is present, it is very important to take the time to thoroughly rinse the equipment and surroundings.

7.Always rinse the empty coil cleaner bottle, cap tightly and dispose of properly.

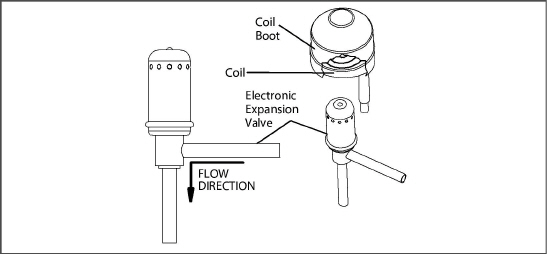

7.17Electronic Expansion Valve (EEV)

The electronic expansion valve (EEV) is an automatic device which maintains required superheat of the refrigerant gas leaving the evaporator. The valve functions are: (a) automatic response of refrigerant flow to match the evaporator load and (b) prevention of liquid refrigerant entering the compressor. Unless the valve is defective, it seldom requires any maintenance

1.Pump down the compressor (see Section 7.4) and frontseat both suction and discharge valves.

2.Turn unit power off and remove power from the unit.

3.Remove coil.

4.Remove the valve. The preferred method of removing the valve is to cut the connection between the brazed section and the valve, using a small tube cutter. Remove the valve.

Alternately, use a wet rag to keep valve cool. Heat inlet and outlet connections to valve body and remove valve.

5.Clean the valve stem with mild cleaner, if necessary.

1.Reverse steps 1 through 4 above to install a new valve. Install valve and screen with cone of screen pointing into liquid line at inlet to the valve.

2.During installation, make sure the EEV coil is snapped down fully, and the coil retention tab is properly seated in one of the valve body dimples. Also, ensure that coil boot is properly fitted over valve body (see Figure 7.11).

Figure 7.11 Electronic Expansion Valve

3.Replace the filter drier.

4.Evacuate to 500 microns by placing vacuum pump on liquid line and suction service valve.

5.Open liquid line service valve and check refrigerant level.

6.Check superheat (see Section 3.2).

7.Check unit operation by running a Pre-trip (see Section 4.8).

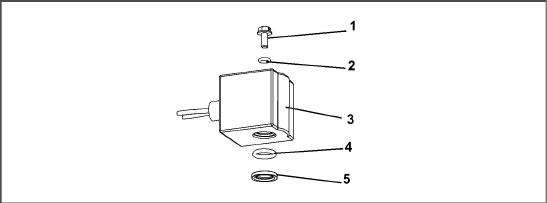

7.18Economizer Solenoid Valve (ESV)

7.18.1Removing a Solenoid Valve Coil:

1.Turn unit power off and remove power from the unit. Disconnect leads.

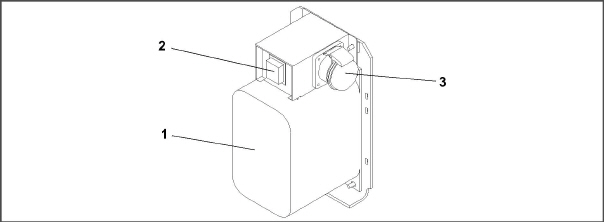

2.Remove top screw and o-ring. Remove coil and save mounting hardware, seals and spacer for reuse (see Figure 7.12). Refer to step d. for valve coil replacement.

Figure 7.12 Coil View of Economizer Solenoid Valve (ESV)

3)Solenoid Coil, Enclosing Tube and Body

- - - - -

7.18.2Removing the Solenoid Valve

1.Pump down the compressor (see Section 7.4) and frontseat both suction and discharge valves.

2.Remove the valve. The preferred method of removing the solenoid valve is to cut the connection between the brazed section and the valve, using a small tube cutter. Remove the valve.

Alternately, heat inlet and outlet connections to valve body and remove valve.

3.Clean the valve stem with mild cleaner, if necessary.

7.18.3Installing the Solenoid Valve

1.Fit the new solenoid valve into position and braze. Use a wet rag to keep valve cool whenever brazing.

7.18.4Installing the Solenoid Valve Coil:

1.Install the brass spacer on the valve stem.

2.Lubricate both o-rings with silicone provided in the kit.

3.Install bottom coil o-ring on the valve stem.

4.Install the solenoid coil on the valve stem.

5.Place the top coil o-ring on the coil mounting screw and secure the coil to the valve using a torque wrench. Torque the screw to 25 in-lbs.

6.Connect coil wires using butt-splices and heat shrink tubing.

7.19Economizer Expansion Valve (EXV)

The economizer expansion valve (EXV) is an automatic device that maintains constant superheat of the refrigerant gas leaving at the point of bulb attachment, regardless of suction pressure.

Unless the valve is defective, it seldom requires maintenance other than periodic inspection to ensure that the thermal bulb is tightly secured to the suction line and wrapped with insulating compound.

The economizer expansion valve is a hermetic valve, it does not have adjustable superheat (see Figure 7.13).

Figure 7.13 Economizer Expansion Valve

7.19.1Removing the Economizer Expansion Valve

1.Pump down the compressor (see Section 7.4) and frontseat both suction and discharge valves. Evacuate if unit is not equipped with service valves (see Section 7.6.1).

2.Turn unit power off and remove power from the unit.

3.Remove cushion clamps located on the inlet and outlet lines.

4.Remove insulation (Presstite) from expansion valve bulb.

5.Unstrap the bulb, located on the economizer line.

6.Remove the valve. The preferred method of removing the valve is to cut the connection between the brazed section and the valve, using a small tube cutter. Remove the valve.

Alternately, use a wet rag to keep valve cool. Heat inlet and outlet connections to valve body and remove valve.

7.Clean the valve stem with mild cleaner, if necessary.

7.19.2Installing the Economizer Expansion Valve

1.The economizer expansion valve should be wrapped in a soaked cloth for brazing.

2.Braze inlet connection to inlet line.

3.Braze outlet connection to outlet line.

4.Reinstall the cushion clamps on inlet and outlet lines.

5.Replace filter drier (see Section 7.13).

6.Evacuate to 500 microns by placing vacuum pump on liquid line and suction service valve.

7.Check economizer expansion valve superheat (see Section 3.2).

7.20Digital Unloader Valve (DUV)

1.Pump down the compressor (see Section 7.4) and frontseat both suction and discharge valves. In the event the DUV is stuck open and compressor cannot pump down, remove charge.

2.Turn unit power off and remove power from the unit.

3.Loosen bolt on top of the DUV and remove coil assembly.

There is a small spacer tube between the top of the valve and the 12 VDC coil that needs to be reinstalled into the solenoid valve coil. When removing the coil, it may fall out when lifted from the valve body. Take care that the spacer is not lost; the valve will not function correctly without it.

4.Remove clamps holding the DUV to the discharge line.

5.Loosen the nuts attaching the DUV to the top of the compressor.

6.Remove the valve. The preferred method of removing the solenoid valve is to cut the connection between the brazed section and the valve, using a small tube cutter. Remove the valve (see Figure 7.14).

Alternately, use a wet rag to keep valve cool. Heat outlet connection to valve body and remove valve.

Figure 7.14 View of Digital Unloader Valve (DUV) Assembly

- - - - -

7.Examine compressor and service valves. Ensure that the O-ring is not stuck in the gland of the valve.

8.Discard the O-ring on the O-ring face seal connection.

1.Lubricate the gland shoulder area and O-ring with refrigerant oil.

2.Fit new valve in position and hand-tighten the O-ring nut.

3.Use a wet rag to keep valve cool while brazing. Braze DUV to service valve connection.

4.Reinstall and tighten the brackets that secure the valve body to the discharge line.

5.Torque O-ring face seal connections to 18 to 20 ft-lbs.

6.Install the coil onto the valve body and tighten the attachment bolt.

Confirm that the small spacer tube is inserted into the coil prior to attaching it to the valve body. The valve will not function correctly without it.

7.Leak check and evacuate low side of unit as applicable (see Section 7.6.1).

8.Open service valves.

Controller function code Cd41 is a configurable code that allows timed operation of the automatic valves for troubleshooting. Test sequences are provided in Table 7–1. Capacity mode (CAP) allows alignment of the economizer solenoid valve in the standard and economized operating configurations. DUV Capacity Modulation,% Setting (PCnt) and Electronic Expansion Valve (EEV) allows opening of the digital unloader valve and electronic expansion valve, respectively, to various percentages. If the unit is equipped with an LIV, the Liquid Valve Setting allows the LIV to be automatically controlled, or manually opened and closed.

The Override Timer (tIM) selection is also provided to enter a time period of up to five minutes, during which the override(s) are active. If the timer is active, valve override selections will take place immediately. If the timer is not active, changes will not take place for a few seconds after the timer is started.When the timer times out, the override function is automatically terminated and the valves return to normal machinery control. To operate the override:

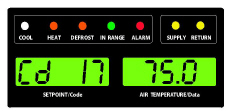

1.Press the CODE SELECT key then press an Arrow key until Cd41 is displayed in the left window. The right window will display a controller communications code.

2.Press the ENTER key. The left display will show a test name alternating with the test setting or time remaining. Use an Arrow key to scroll to the desired test. Press the ENTER key, SELCt will appear in the left display.

3.Use an Arrow key to scroll to the desired setting, and then press the ENTER key. Selections available for each of the tests are provided in Table 7–1.

4.If the timer is not operating, follow the above procedure to display the timer. Use an Arrow key to scroll to the desired time interval and press ENTER to start the timer.

5.The above described sequence may be repeated during the timer cycle to change to another override.

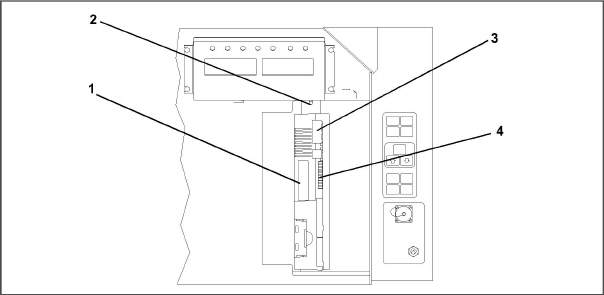

If the unit does not start, check the following:

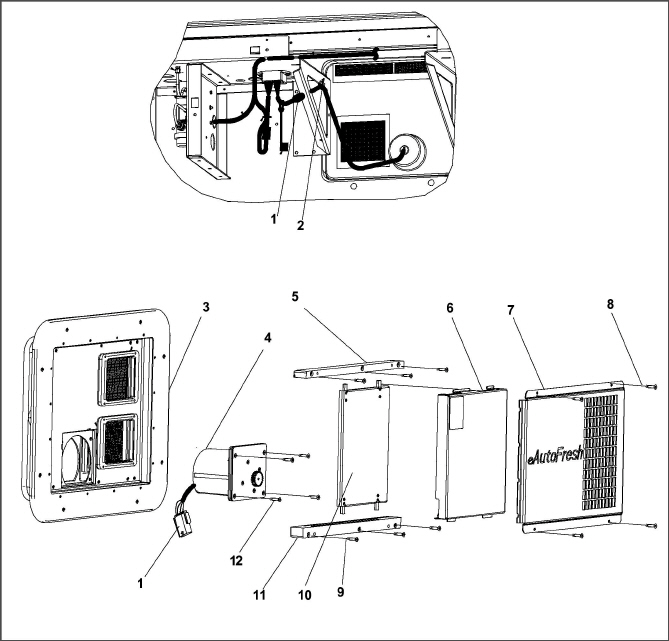

1.Verify the 460 VAC (yellow) power cable is plugged into the receptacle (see Figure 7.15) and locked in place.

2.Verify that circuit breakers CB-1 and CB-2 are in the “ON” position. If the circuit breakers do not hold in, check voltage supply.

3.There is no internal protector for this transformer design. So, no checking of the internal protector is required.

4.Using a voltmeter, and with the primary supply circuit ON, check the primary (input) voltage (460 VAC). Next, check the secondary (output) voltage (230 VAC). The transformer is defective if output voltage is not available.

1)Dual Voltage Modular Autotransformer

2)Circuit Breaker (CB-2) 230-Volt

- - - - -

Do not remove wire harnesses from circuit boards unless you are grounded to the unit frame with a static safe wrist strap or equivalent static drain device.

Remove the controller module and unplug all connectors before performing any arc welding on any part of the container.

The guidelines and cautions provided herein should be followed when handling the modules. These precautions and procedures should be implemented when replacing a module, when doing any arc welding on the unit, or when service to the refrigeration unit requires handling and removal of a module.

1.Obtain a grounding wrist strap (Carrier Transicold P/N 07-00304-00) and a static dissipation mat (Carrier Transicold P/N 07-00277-00). The wrist strap, when properly grounded, will dissipate any potential static buildup on the body. The dissipation mat will provide a static-free work surface on which to place and/or service the modules.

2.Disconnect and secure power to the unit.

3.Place strap on wrist and attach the ground end to any exposed unpainted metal area on the refrigeration unit frame (bolts, screws, etc.).

4.Carefully remove the module. Do not touch any of the electrical connections if possible. Place the module on the static mat.

5.The strap should be worn during any service work on a module, even when it is placed on the mat.

7.23.2Controller Troubleshooting

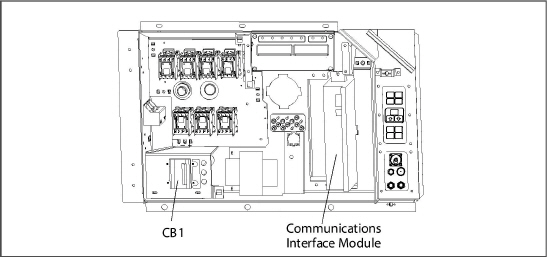

A group of test points (TP, see Figure 7.16) are provided on the controller for troubleshooting electrical circuits (see schematic diagram sections). A description of the test points is provided in Table 7–2.

Use a digital voltmeter to measure AC voltage between TP’s and ground (TP9), except for TP8.

Figure 7.16 Controller Section of the Control Box

1)Controller Software Programming Port

- - - - -

7.23.3Controller Programming Procedure

The unit must be OFF whenever a programming card is inserted or removed from the controller programming port.

1.Turn unit OFF, via start-stop switch (ST).

2.Insert

software/programming PCMCIA card containing the following (example) files

into the programming/software port (see Figure 7.16):

menuDDMM.ml3, this file allows

the user to select a file/program to upload into the controller.

cfYYMMDD.ml3, multi-configuration

file.

3.Turn unit ON, via start-stop switch (ST).

Procedure for Software Versions prior to 5328 and/or Cards Without Updated Menu Option (menu0111.ml)

a. Procedure for Loading Operational Software:

1.The display module will display the message ruN COnFG. (If a defective card is being used the display will blink the message “bAd CArd.” Turn start-stop switch OFF and remove the card.)

2.Press the Up or Down Arrow key until the display reads, LOAd 53XX for Scroll.

3.Press the ENTER key on the keypad.

4.The display will alternate to between PrESS EntR and rEV XXXX.

5.Press the ENTER key on the keypad.

6.The display will show the message “Pro SoFt”. This message will last for up to one minute.

7.The display module will go blank briefly, then read “Pro donE” when the software loading has completed. (If a problem occurs while loading the software: the display will blink the message “Pro FAIL” or “bad 12V.” Turn start-stop switch OFF and remove the card.)

8.Turn unit OFF, via start-stop switch (ST).

9.Remove the PCMCIA card from the programming/software port and return the unit to normal operation by placing the start-stop switch in the ON position.

10.Turn power on and wait about 15 seconds for the new software to load into the controller memory. The status LED will flash quickly and the display will remain blank as the controller loads the new software. When complete, the controller will reset and power up normally.

11.Wait for default display, setpoint on the left, and control temperature on the right.

12.Confirm software is correct using keypad code select 18 to view Cd18 XXXX.

13.Turn power off. Operational software is loaded.

b. Procedure for Loading Configuration Software:

1.Turn unit OFF using start-stop switch (ST).

2.Insert

software/programming PCMCIA card containing the following (example) files

into the programming/software port (see Figure 7.16):

menuDDMM.ml3, this file allows

the user to select the file/program to upload into the controller.

cfYYMMDD.ml3, multi-configuration

file.

3.Turn unit ON using start-stop switch (ST).

4.The display module will display the message ruN COnFG. (If a defective card is being used the display will blink the message “bAd CArd.” Turn start-stop switch OFF and remove the card.)

5.Press the ENTER key on the keypad.

6.The display module will go blank briefly and then display “551 00”, based on the operational software installed.

7.Press the Up or Down Arrow key to scroll through the list to obtain the proper model dash number. (If a defective card is being used, the display will blink the message “bAd CArd.” Turn start-stop switch OFF and remove the card.)

8.Press the ENTER key on the keypad.

9.When software loading has successfully completed, the display will show the message “EEPrM donE.” (If a problem occurs while loading the software, the display will blink the message “Pro FAIL” or “bad 12V.” Turn start-stop switch OFF and remove the card.)

10.Turn unit OFF using start-stop switch (ST).

11.Remove the PCMCIA card from the programming/software port and return the unit to normal operation by placing the start-stop switch in the ON position.

12.Confirm the correct model configuration by using the keypad to select Cd20. The model displayed should match the unit serial number plate.

Procedure for Software Versions 5350 and Greater With Updated Menu Option (menu0115.ml)

The updated menu option allows the operational software to be loaded, and time and container identification to be set.

a. Procedure for Loading Operational Software:

1.The display module will display the message SetUP.

2.Press the Up or Down Arrow key until the display reads, LOAd 53XX for Scroll.

3.Press the ENTER key on the keypad.

4.The display will alternate to between PrESS EntR and rEV XXXX.

5.Press the ENTER key on the keypad.

6.The display will show the message “Pro SoFt”. This message will last for up to one minute.

7.The display module will go blank briefly, then read “Pro donE” when the software loading has loaded. (If a problem occurs while loading the software: the display will blink the message “Pro FAIL” or “bad 12V.” Turn start-stop switch OFF and remove the card.)

8.Turn unit OFF, via start-stop switch (ST).

9.Remove the PCMCIA card from the programming/software port and return the unit to normal operation by placing the start-stop switch in the ON position.

10.Turn

power on and wait about 15 seconds for the new software to load into the

controller memory. The status LED will flash quickly and the display will

remain blank as the controller loads the new software.

When complete, the controller will reset and power up normally.

11.Wait for default display, setpoint on the left, and control temperature on the right.

12.Confirm software is correct using keypad code select 18 to view Cd18 XXXX.

13.Turn power off. Operational software is loaded.

b. Procedure for Loading Configuration Software:

1.Turn unit OFF using start-stop switch (ST).

2.Insert

software/programming PCMCIA card containing the following (example) files

into the programming/software port (see Figure 7.16):

menuDDMM.ml3, this file allows

the user to select the file/program to upload into the controller.

cfYYMMDD.ml3, multi-configuration

file.

3.Turn unit ON using start-stop switch (ST).

4.Press the Up or Down Arrow key key until the display reads Set UP.

5.Press the ENTER key on the keypad.

6.Press the Up or Down Arrow key until the display reads XXXX the message ruN COnFG. (If a defective card is being used the display will blink the message “bAd CArd.” Turn the start-stop switch OFF and remove the card.)

7.Press the ENTER key on the keypad.

8.The display module will go blank briefly and then display “551 00”, based on the operational software installed.

9.Press the Up or Down Arrow key to scroll through the list to obtain the proper model dash number. (If a defective card is being used, the display will blink the message “bAd CArd.” Turn start-stop switch OFF and remove the card.)

10.Press the ENTER key on the keypad.

11.When software loading has successfully completed, the display will show the message “EEPrM donE.” (If a problem occurs while loading the software, the display will blink the message “Pro FAIL” or “bad 12V.” Turn start-stop switch OFF and remove the card.)

12.Turn unit OFF using start-stop switch (ST).

13.Remove the PCMCIA card from the programming/software port and return the unit to normal operation by placing the start-stop switch in the ON position.

14.Confirm correct model configuration using the keypad to choose code 20 (CD20). The model displayed should match the unit serial number plate.

c. Procedure for Setting the Date and Time:

1.Press the Up or Down Arrow key until display reads Set TIM.

2.Press the ENTER key on the keypad.

3.The first value to be modified is the date in YYYY-MM-DD format. The values will be entered from right to left. Press the UP or DOWN ARROW key to increase or decrease the values. The ENTER key will enter the information for the current field and move to the next value; the CODE SELECT key will allow modification of the previous value.

4.Press the ENTER key on the keypad.

5.The next value to be modified is the time in HH MM format. The values will be entered from right to left. Press the Up or Down Arrow key to increase or decrease the values. The ENTER key will enter the information for the current field and move to the next value; the CODE SELECT key will allow modification of the previous value.

6.Press the ENTER key on the keypad. The date and time will not be committed until start up procedures are completed on the next power up.

d. Procedure for Setting the Container ID:

The characters will be preset to the container ID already on the controller. If none exist, the default will be AAAA0000000.

1.Press the Up or Down Arrow key until display reads Set ID.

2.Press the ENTER key on the keypad.

3.Values will be entered from right to left. Press the Up or Down Arrow key to increase or decrease the values. ENTER will enter the information for the current field and move to the next value; CODE SELECT will allow modification of the previous value.

4.When the last value is entered, press the ENTER key to enter the information to the controller; the CODE SELECT key will allow modification of the previous value.

7.23.4Removing and Installing a Controller

Removal:

1.Disconnect all front wire harness connectors and move wiring out of way.

2.The lower controller mounting is slotted, loosen the top mounting screw (see Figure 7.16) and lift up and out.

3.Disconnect the back connectors and remove module.

4.When removing the replacement module from its packaging, note how it is packaged.When returning the old module for service, place it in the packaging in the same manner as the replacement. The packaging has been designed to protect the module from both physical and electrostatic discharge damage during storage and transit.

Installation:

1.Install the module by reversing the removal steps.

2.Torque values for mounting screws (item 2, see Figure 7.16) are 0.23 mkg (20 inch-pounds). Torque value for the connectors is 0.12 mkg (10 inch-pounds).

Standard Battery Location (Standard Cells):

1.Turn unit power OFF and disconnect power supply.

2.Slide bracket out and remove old batteries (see Figure 4.4, Item 8.)

3.Install new batteries and slide bracket into control box slot.

Use care when cutting wire ties to avoid nicking or cutting wires.

Standard Battery Location (Rechargeable Cells):

1.Turn unit power OFF and disconnect power supply.

2.Disconnect battery wire connector from control box.

3.Slide out and remove old battery and bracket (see Figure 4.4, Item 8.)

4.Slide new battery pack and bracket into the control box slot.

5.Reconnect battery wire connector to control box and replace wire ties that were removed.

Secure Battery Option (Rechargeable Cells Only):

1.Turn unit power OFF and disconnect power supply.

2.Open control box door and remove both the high voltage shield and clear plastic rain shield (if installed).

3.Disconnect the battery wires from the “KA” plug positions 14, 13, 11.

4.Using Driver Bit, Carrier Transicold part number 07-00418-00, remove the 4 screws securing the display module to the control box. Disconnect the ribbon cable and set the display module aside.

The battery wires must face toward the right.

5.Remove the old battery from the bracket and clean bracket surface. Remove the protective backing from the new battery and assemble to the bracket. Secure battery by inserting the wire tie from the back of the bracket around the battery, and back through the bracket.

6.Reconnect the ribbon cable to display and re- install the display.

7.Route the battery wires from the battery along the display harness and connect the red battery wire and one end of the red jumper to “KA14,” the other end of the red jumper wire to “KA11,” and the black wire to “KA13.”

8.Replace wire ties that were removed.

7.24Temperature Sensor Service

Service procedures for the return recorder (RRS), return temperature (RTS), supply recorder (SRS), supply temperature (STS), ambient temperature (AMBS), defrost temperature (DTS), evaporator temperature (ETS), and compressor discharge temperature (CPDS) sensors are provided here.

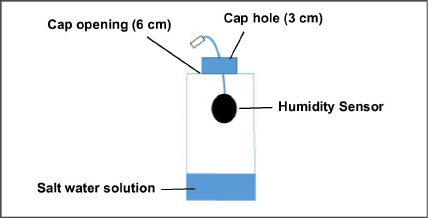

The ice-water bath is a method for testing the accuracy of sensors by submerging the sensors in an insulated container with ice cubes or chipped ice, then filling voids between ice with water and agitating until mixture reaches 0°C (32°F) measured on a laboratory thermometer.

Notes:

•Wherever possible, use a thermometer that is regularly calibrated by an accredited test lab. Contact your instrument representative if the reference thermometer is not showing correct readings.

•Always use a temperature measurement reference instrument which is of higher accuracy than the device checked – for e.g., a thermometer with a rated accuracy of +/- 0.2 °C should be used to check a device with a rated accuracy +/- 0.3 °C.

•A thermally insulated container, tub open to atmosphere and large enough to contain crushed ice and water should be used. The tub should be large enough to contain the unit’s sensor and the reference thermometer.

•Enough distilled water should be available to make ice cubes and to set up a proper and stable ice-water triple-point mixture. Prepare ice using distilled water.

•Pre-cool distilled water for testing.

Procedure:

1.Prepare a mixture of clean ice using distilled water in a clean insulated container. If possible, the person handling should be wearing latex gloves.

a.Crush or chip the ice to completely fill the container. The finer the ice particles, the more accurate the mixture.

b.Add enough pre-cooled distilled water to fill the container.

c.Stir the mixture for a minimum of 2 minutes to ensure water is completely cooled and good mixing has occurred.

d.The mixture should generally contain about 85% ice with the distilled water occupying the rest of the space.

e.Add more ice as the ice melts.

2.Stir the ice water slurry mixture to maintain a temperature 0°C (32°F).

3.Constantly monitor the temperature of the ice water slurry with your reference thermometer. Ensure that the temperature of the bath has stabilized. The criterion for stability generally is to take two readings at 1 minute intervals, and the two readings should give you 0°C (32°F).

7.24.2Sensor Checkout Procedure

This procedure is performed to verify the accuracy of a temperature sensor:

1.Remove the sensor and place in a 0°C (32°F) ice-water bath. The ice-water bath is prepared by filling an insulated container (of sufficient size to completely immerse bulb) with ice cubes or chipped ice, then filling voids between ice with water and agitating until mixture reaches 0°C (32°F) measured on a laboratory thermometer.

2.Start unit and check sensor reading on the control panel. The reading should be 0°C (32°F). If the reading is correct, reinstall sensor; if it is not, continue with the following.

3.Turn unit OFF and disconnect power supply.

4.See Section 7.23 and remove controller to gain access to the sensor plugs.

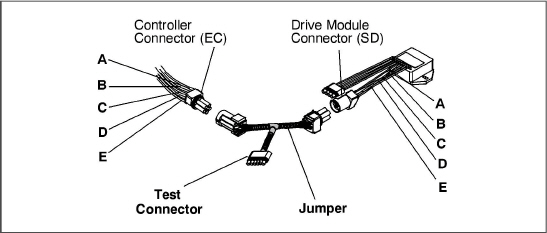

5.Using the plug connector marked “EC” that is connected to the back of the controller, locate the sensor wires (RRS, RTS, SRS, STS, AMBS, DTS, or CPDS as required). Follow those wires to the connector and using the pins of the plug, measure the resistance. Values are provided in Table 7–3 and Table 7–4.

Due to the variations and inaccuracies in ohmmeters, thermometers or other test equipment, a reading within 2% of the chart value would indicate a good sensor. If a sensor is defective, the resistance reading will usually be much higher or lower than the resistance values given.

7.24.3GDP Supply and Return Sensor Calibration

European Commission GDP (Good Distribution Practices) guidelines, which are used worldwide, call for the equipment used to control or monitor environments where medicinal products are stored or transported be calibrated in accordance with pharmaceutical shipper specifications, typically every six months or annually.

This procedure explains how to perform a GDP calibration of the supply (STS/SRS) and return (RTS/RRS) sensors using DataLINE software version 3.1 or higher. The calibration procedure should be conducted in pairs (STS/SRS, or RTS/RRS) and it is recommended to calibrate before the full pre-trip inspection.

Before removing the Supply or Return air sensors from the unit, turn the ON/OFF switch and circuit breaker to the OFF position. Disconnect the power plug from the unit. Follow proper lockout/tagout procedures to ensure the power cannot inadvertently be energized. It is important that all dismantling work is done and tools and personnel are away from the unit before powering on the unit for calibration.

When performing the Return Air Sensor calibration, disconnect both evaporator motors.

Before proceeding with the calibration procedure, ensure that controller software version is 5368 or higher and DataLINE version 3.1 or higher is installed onto the download device. Only the latest DataLINE and controller software will allow users to carry out Good Distribution Practice (GDP) calibration. Do not downgrade the software after installing the latest software.

Before proceeding with the calibration procedure, it is recommended to check the sensors by running pre-trip P5-0. This test checks the sensor values. If the test fails, identify and correct the faulty sensor and rerun the test.

Tools Required:

•Socket screwdrivers set

•Phillips screwdriver

•Standard hand tools

•Interrogator cable

•Laptop with DataLINE 3.1 or above installed

•Clean insulated container for distilled water and ice

•A regularly calibrated reference thermometer, recommended to be of accuracy up to 2 decimal places.

GDP Calibration, Removing Supply Sensors (STS/SRS) from Unit:

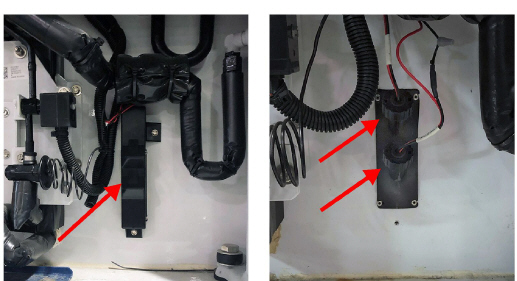

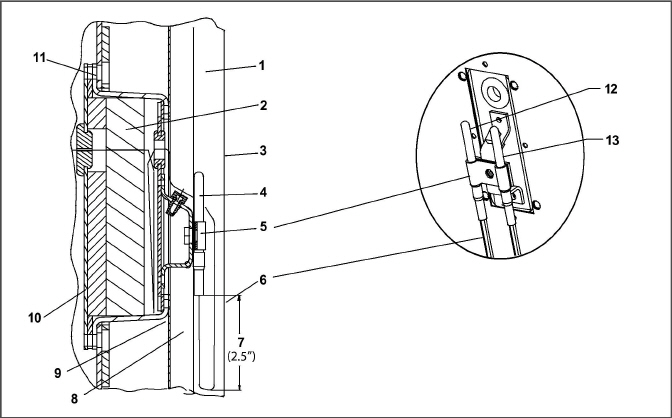

1.Locate the supply sensors cover assembly on the suction side of the compressor. Remove the two fasteners securing the cover of the sensors (see Figure 7.17).

2.Remove the cover and rotate the supply air sensors, STS/SRS, in a clockwise direction and remove the sensors from the sensor housing (see Figure 7.17).

Figure 7.17 Supply Sensors - Cover Assembly and Sensors

GDP Calibration, Removing Return Sensors (RTS/RRS) from Unit:

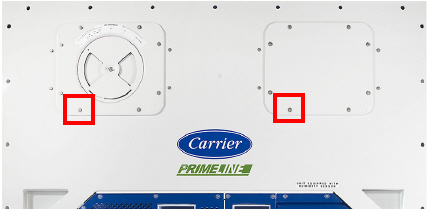

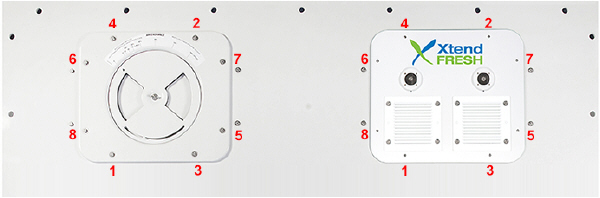

1.Remove both front access panels from the unit by removing 8 fasteners from each panel (see Figure 7.18). Save all hardware for re-installation.

Figure 7.18 Removing Front Access Panels

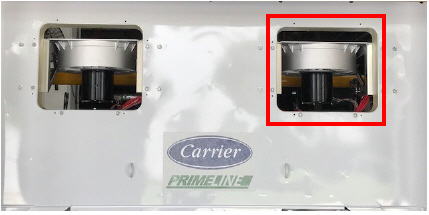

2.On the right side, disconnect the fan motor wiring, loosen the fastener and remove (slide) the evaporator motor from the unit (see Figure 7.19).

Figure 7.19 Removing Evaporator Motor

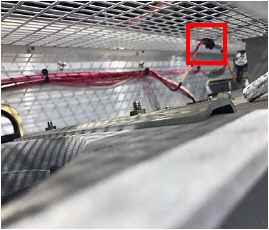

3.Loosen the fastener on the sensor bracket (see Figure 7.20).

Figure 7.20 Return Sensors - Bracket

4.Cut all the wire ties (see Figure 7.21) that are securing the sensors to the harness and remove sensor.

Figure 7.21 Return Sensors - Cutting Wire Ties

GDP Calibration, Perform Calibration:

1.Connect the interrogator cable to the interrogator port. Then, power on the unit.

Before powering on the unit, it is important to ensure that all dismantling work is done and tools are away and service personnel are not working on the unit at the time of power on.

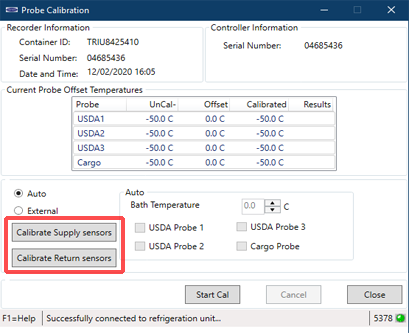

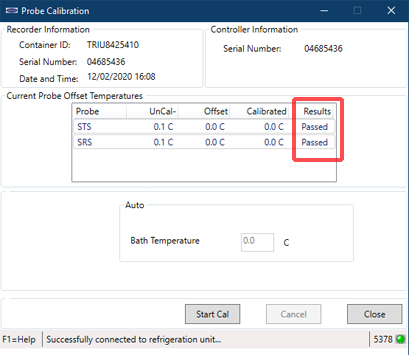

2.Open DataLINE version 3.1 or above. From the DataLINE launch pad, click on the Probe Calibration button (see Figure 7.22) to go to the Probe Calibration screen. A pop-up window will appear reminding the user to ensure proper ice bath temperature. Click OK to acknowledge.

Figure 7.22 DataLINE - Probe Calibration

3.On the Probe Calibration screen, click on the Calibrate Supply sensors or Calibrate Return sensors button (see Figure 7.23).

Figure 7.23 DataLINE - Calibrate Sensors Button

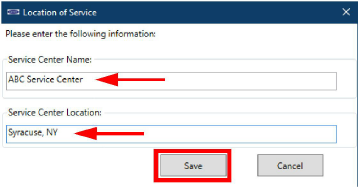

4.A Location of Service pop-up window will appear (see Figure 7.24). In the appropriate fields, enter the Service Center Name and Service Center Location where the calibration is being performed. Then, click the Save button. A pop-up window will appear reminding the user to ensure proper ice bath temperature. Click OK to acknowledge and remember to maintain the Ice bath at 0°C (32°F).

Figure 7.24 DataLINE - Enter Service Center Information

5.Prepare the ice bath. Refer to the Ice Bath Preparation procedure.

Ensure that the set-up (i.e. ice bath, sensors, reference thermometer) has reached a stable state before beginning the calibration process. Ensure that the set-up is clean and the reference thermometer is regularly maintained and calibrated.

6.Place the ice bath in a location near sensors (see Figure 7.25). For Return Sensors, place the ice bath on an elevated platform (ladder) of appropriate height.

7.Once temperature stability is ensured, submerge the sensors in the ice water slurry. Make certain that the sensors do not contact the container sides or bottom, or each other. Continuously stir the slurry mixture during calibration.

8.Ensure that the Ice bath is at 0°C (32°F) using the calibrated reference thermometer. Confirm that the sensor readings have stabilized and the sensors are within +/- 0.3°C (0.5°F). The readings can be taken from the Uncal column in the Current Probe Offset Temperatures table.

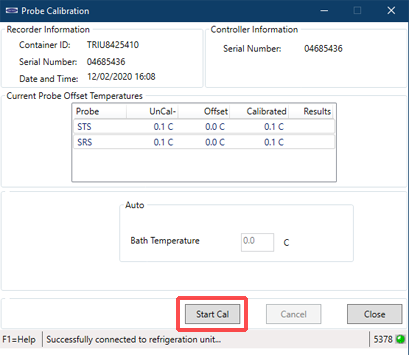

9.Then, after confirming the sensor readings have stabilized, click on the Start Cal button (see Figure 7.26). After clicking Start Cal, the process begins automatically and will complete in less than 5 minutes. Continue to stir the ice bath during testing. Calibration will fail if the stability cannot be achieved or the sensor offset is greater than 0.3°C (0.5°F).

Figure 7.26 DataLINE - Start Cal Button

10.Once the calibration has completed, a pop-up will appear with the message Calibrate Complete. Click OK to acknowledge and the results will then be displayed on the screen in the Results column (see Figure 7.27).

Calibration will fail if the stability cannot be achieved or the sensor offset is greater than 0.3°C (0.5°F). The validity of a sensor can be checked by hand warming the sensors to see if there are changes in the readings on the DataLINE screen. If calibration will not complete, replace and recalibrate the sensors. Refer to the Sensor Replacement procedure.

Figure 7.27 DataLINE - Calibration Results

11.After completing the calibration event, download a DCX file and check that all of the following information is captured: service center name, location, the results of the calibration and the offset applied. Ensure that all the information is captured and the event is considered a success when all the intended sensors in calibration have passed.

If there is “uncal” in the download, it means that the calibration process was not completed.

After the completion of the calibration, restore the unit to its original state.

1.Turn unit power OFF and disconnect power supply.

Include white date code label when cutting out and removing defective sensors. The label could be required for warranty returns.

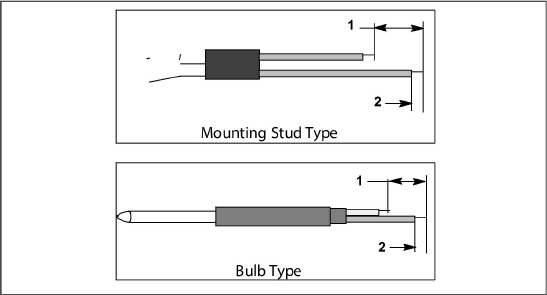

2.Cut cable. Slide the cap and grommet off a bulb type sensor and save for reuse. Do not cut the grommet.

3.Cut one wire of existing cable 40 mm (1-1/2 inches) shorter than the other wire.

4.Cut replacement sensor wires (opposite colors) back 40 mm (1-1/2 inches) (see Figure 7.28.)

1)40 mm (1 1/2 in), 2 or 3 wires as required

- - - - -

5.Strip back insulation on all wiring 6.3 mm (1/4 inch).

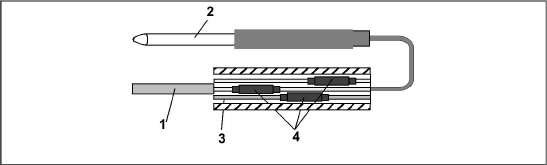

6.Slide a large piece of heat shrink tubing over the cable, and place the two small pieces of heat shrink tubing, one over each wire, before adding crimp fittings (see Figure 7.29).

Figure 7.29 Sensor and Cable Splice

3)Large Heat Shrink Tubing (1)

4)Heat Shrink Tubing, 2 or 3 as required

- - - - -

7.If required, slide the cap and grommet assembly onto the replacement sensor.

8.Slip crimp fittings over dressed wires (keeping wire colors together). Make sure wires are pushed into crimp fittings as far as possible and crimp with crimping tool.

9.Solder spliced wires with a 60% tin and 40% lead Rosincore solder.

10.Slide heat shrink tubing over each splice so that ends of tubing cover both ends of crimp (see Figure 7.29).

11.Heat tubing to shrink over splice. Make sure all seams are sealed tightly against the wiring to prevent moisture seepage.

Do not allow moisture to enter wire splice area as this may affect sensor resistance.

12.Slide large heat shrink tubing over both splices and shrink.

13.Position sensor in unit (see Figure 7.29) and re-check sensor resistance.

14.Reinstall sensor (see Section 7.24.5).

The P5 Pre-Trip test must be run to deactivate probe alarms (see Section 5.9).

7.24.5Sensors STS and SRS Reinstallation

To properly position a supply sensor, the sensor must be fully inserted into the probe holder mounting clamp. See Figure 7.30. Do not allow heat shrink covering to contact the probe holder. For proper placement of the sensor, be sure to position the enlarged positioning section of the sensor against the side of the mounting clamp. This positioning will give the sensor the optimum amount of exposure to the supply air stream, and will provide accurate temperature readings to the controller.

Figure 7.30 Supply Sensor Positioning

- - - - -

7.24.6Sensors RRS and RTS Reinstallation