November 2016 Issue

Inside This Issue:

XtendFRESH™ System Enhancements

Based on customer feedback, several new features have been added to the XtendFRESH option both from the software side with version 5366 and hardware side with PID NT2727 and greater.

On the software side, features were added to make the viewing of the XtendFRESH system state easier.

On the main display screen, an indicator was added to show when the XtendFRESH system is operating; “FrESH” will be displayed in the left hand display and the right hand display will flash “ACtiV” when the XtendFRESH system is on. This message will alternate with the unit set point and control temperature at 5 second intervals.

The ability to view the XtendFRESH system values in code select 44 (Cd44) was also added. By selecting Cd44, the user will be able to view CO2 and O2 set points, CO2% and O2%, and the O2 sensor voltage in millivolts by pressing arrow key up or down to switch between the values.

|

Left Display |

Right Display |

|

|---|---|---|

|

For CO2 set point |

CO2SP |

CO2 set point |

|

For CO2 concentration |

CO2 |

CO2 concentration |

|

For O2 set point |

O2SP |

O2 set point |

|

For O2 concentration |

O2 |

O2 concentration |

|

For O2 voltage |

O2v |

O2 voltage in mV |

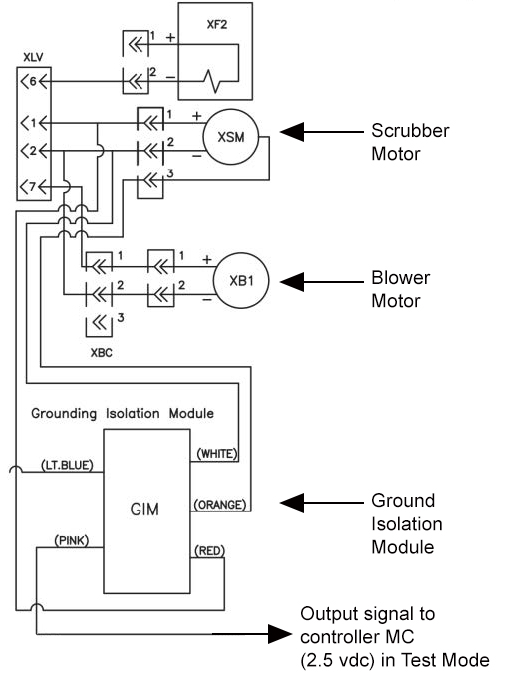

On the hardware side, for new production units, the scrubber motor was enhanced with an output signal through the Ground Isolation Module (GIM) to the controller to verify motor rotation. Doing this helps to ensure that the scrubber is rotating during normal operation while also eliminating the need for removing the rear access panel to help ensure that the scrubber motor is rotating as part of the unit’s XtendFRESH system test mode. This feature also allows for the addition of an alarm indicator (AL96) when the scrubber motor fails to rotate.

For the PTI, when test mode is selected via code select 43 to “tESt” mode one of the following results will be displayed. At end of “tESt” mode “Scrub” “PASS” or “Scrub” “FAIL” will be posted for the last 10 seconds of “tESt” mode, prior to the calibration counter being started.

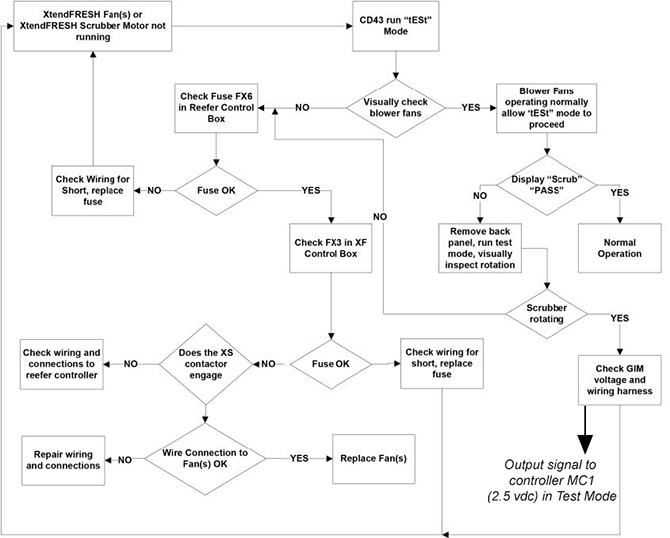

If “Scrub” FAIL” or AL96 is posted, this indicates that you need to troubleshoot the scrubber circuit as follows:

PrimeLINE Unit P8-1 Software Logic

Currently the PrimeLINE® unit Pre-trip P8-1 Perishable Mode Pulldown Test has the following logic:

At the start of the test, the controller will help ensure the box temperature is at least 15.6°C (raising the temperature if necessary). The set point is then changed to 0°C, and a 180-minute timer is started. The unit will then start to pull down the temperature to the 0°C set point. The test passes if the container temperature reaches set point before the 180-minute timer expires.

An enhanced logic is added to the software version 5366 for High Ambient Temperature conditions. When Pre-trip P8-1 is initiated via Auto Pre-trip or Manual Pre-trip P8, evaporator fan speed switches from default high speed to low speed when the following conditions are met:

•Ambient Temperature is ≥ 45°C AND

•Supply Air Temperature ≥ 6°C AND

•Ambient Temperature Sensor is not faulty

The evaporator fan speed switches back to default high speed evaporator fan if the low speed fan has been running for 1 hour 20 minutes OR Supply Air Temperature < 6°C AND the low speed fan has been running for at least 20 seconds.

Micro-Link 3 Controller / ERR1 / ERR2

The software version 5352 addresses the active alarm ERR1 with the normal aging of the flash memory chip with regards to read/write response times in the Datacorder recorder on older MicroLink™ 3 controllers (3+ years). If an ERR1 is active on a controller, downloading the software “Ml3_serial_number.bin” from TransCentral™ web-site and installing it allows the user to re-enter the controller serial number and reset the ERR1 without loss of any data or having to replace the controller.

During installation of software 5159.ml3 or 5361.ml3 (or greater) in an Micro-Link 3 controller, the controller may become unresponsive for several minutes after the power is turned on or possibly an ERR2 Alarm will occur. Step by step instructions are posted along with the necessary software at the bottom of each release in our TransCentral™ web-site that can be used to reset the ERR2 or unresponsive condition

ThinLINE® unit: “recp51XX_ml3_btldr00YY_field.1024”

PrimeLINE unit: “scrl53XX_ml3_btldr00YY_field.1024”

A controller with ERR1 or ERR2 can be identified through the flashing LED on the front of the controller. The LED will flash the Morse code: (. .-. .-. .---- ) for ERR1, and will flash the Morse code: ( . .-. .-. ..---) for ERR2.

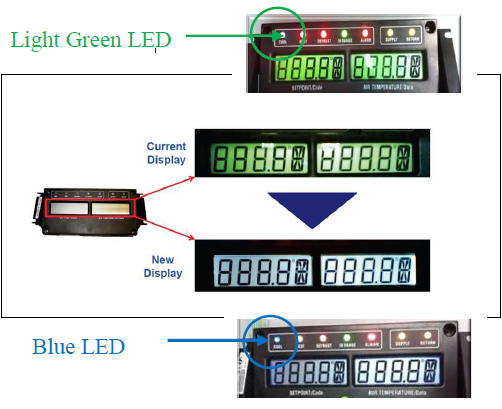

LED Display Change

On Carrier units PID NT2732 and greater the following changes were made to the seven segment digital display.

•Backlight from array of green LEDs to white LEDs

•Change indicator LEDs to surface-mount high-brightness LEDs

•Cool LED (LED7) changed from light green to blue

•New part numbers are 12-00433-06RP (Unit) and 12-00433-07RP (CA)

•The displays are interchangeable.; the -03 (unit) or the -04 (CA) can still be used.

•

A DataCorder recorder event was added as an indicator when the controller alarm list is cleared. The event is now coded as 125 and will be named "controller alarm list cleared" in the next DataLINE software release.

Introduction of Online Training

To improve the overall quality of training and to provide a more measured approach, Carrier Transicold’s container training has been upgraded to provide three levels of certification.

Associate – A set of modules to provide the basic knowledge and information to allow operation of Carrier Transicold container refrigeration equipment. The only prerequisite for completion is 6 months experience working on container reefer units in the last 2 years. It is recommended to complete the modules in numeric order.

Technician – Complementing the initial Associate modules, this instructor-led class brings a technician to the level that they can troubleshoot and fault find on Carrier Transicold equipment. Prerequisites are a total of 12 months of hands-on working experience and completion of the Associates Certificate.

Master Technician – Supplementing the Technician level, by including advanced troubleshooting and introducing the various options that can be included with Container units, this demonstrates the highest knowledge of Carrier container units along with experience working on them. Prerequisites are completion of Technician Certification and 3 years of hands-on experience.

The introduction of the online learning modules in no way removes the need for hands-on training and it should be noted that to obtain the Technician Certificate, a hands-on training class is required. Both Associate and Technician can also be obtained with instructor-led classes. Instructor-led classes, identified in the 2017 global training article, will be renamed and amended for 2017 to ensure a complete link between instructor-led and online learning. Looking in detail to the online course schedule:

|

|

Course Description |

Available |

Associate |

Technician |

|

1 |

Safety |

* |

R |

|

|

2 |

Basic Refrigeration |

Q1 2017 |

E |

|

|

3 |

Basic Electrical |

Q1 2017 |

E |

|

|

4a |

PrimeLINE Unit Component ID |

* |

R1 |

R2 |

|

4b |

ThinLINE Unit Component ID |

Q1 2017 |

R1 |

R2 |

|

5 |

Keypad & Display Functions |

* |

R |

|

|

6 |

Tools & Resources (Schematics, wiring diagrams, manuals & apps) |

* |

R1 |

|

|

7a |

PrimeLINE Unit Operating Sequence & Refrigerant Flow |

* |

R1 |

R2 |

|

7b |

ThinLINE Unit Operating Sequence & Refrigerant Flow |

Q1 2017 |

R1 |

R2 |

|

8 |

Pre-Trip |

2016 |

R |

|

|

2-Day Technician Class (Hands On Troubleshooting) |

2017 |

R |

||

|

10 |

Controller & Software |

R |

||

|

11 |

PrimeLINE Unit II (Troubleshooting) |

R |

||

|

12 |

ThinLINE Unit II (Troubleshooting) |

R |

R = Required

E = Elective (2 day technician class will include modules 10, 11 and 12)

R1 = only one required set, either PrimeLINE or ThinLINE

R2 = Complete second class online prior to instructor-led class

Registration for online classes is the same as for instructor-led classes. Visit http://www. carrier.com/container and go to Service and Support section. Then click on Training, where you can select classes. If you have already registered for instructor-led classes, then you can use the same sign in to register for online classes. Once you register, you will receive an email containing the link to the Carrier Transicold Learning Management System (LMS) and the enrollment key for the first class.

After having registered for the first class, select the link in the email and go to the LMS. The first time a student accesses the LMS, they have to set up an account for their personal training. The information provided will be stored in the U.S to provide verification of the completed training. The enrollment will not work if a general ID or email address is used; each student must have a unique ID and email address. There are notes in the email about how a student can obtain an email address if they

don’t have one. Complete the account set up, and if there are no error messages when you submit the new account, you will receive a confirmation email usually within a few minutes but it can take up to 24 hours. You cannot sign in to the LMS until you have received this confirmation email and clicked on the confirmation link.

Once you have confirmed your account set up, you can sign into the LMS, which will take you to the home page where you can select the course and enter the enrollment key from the original registration email, which will take you into the class material.

•Each module takes between 45 to 60 minutes to complete.

•There are stop and start buttons. You can close out of the class and then return to the class where you left off.

•Each class must be taken one at a time.

•If you have taken a 1 week Container Basic Diploma class in the last 5 years, you can exchange this diploma for the new Technician Certificate.

•If you have taken a 3 day Basic Class in the last 5 years, you can exchange this certificate for the new Associate Certificate.

For these last two, contact your local Field Service Manager and provide a copy of the certificate (you get to keep the original). After verification, you will be sent a new certificate.

Carrier CareMAX Provider

Since the inception of the CareMAX™ program, 18 service companies / locations have successfully implemented the refrigerant management policies and successfully completed the CareMAX audit.

This program, short for Carrier Refrigerant Management Excellence, the CareMAX program sets standards to help Carrier-authorized container service centers better manage refrigerants and refrigerant supplies.

|

Company |

Location |

|---|---|

|

TASESA |

Guayaquil, Ecuador |

|

Contrepair SpA |

La Spezia, Italy |

|

Holland Reefer Service BV |

Rotterdam, The Netherlands |

|

H.C.C.R. Gmbh |

Hamburg, Germany |

|

Illinois Transport Inc. |

Chicago, USA |

|

JPC Reefer Services |

Sydney, Australia |

|

Olinsa SA |

Cartagena, Columbia |

|

Olinsa SA |

Turbo, Columbia |

|

Olinsa SA |

Barranquilla |

|

Olinsa SA |

Santa Marta, Columbia |

|

Reefer Maintenance Services Pty Ltd |

Sydney, Australia |

|

Seamark Reefer Service BV |

Rotterdam, The Netherlands |

|

Servicios Integrados de Transportes Ltda. |

Santiago, Chile |

|

Specialised Refrigeration Services(NZ)Ltd |

Tauranga, New Zealand |

|

Star Container Spain S.A. |

Algeciras |

|

S&T Contemp Co. Ltd. |

Nakorn Pathom, Thailand |

|

S&T Contemp Co. Ltd. |

Bangkok, Thailand |

|

S&T Contemp Co. Ltd |

Chonburi, Thailand |

|

TASESA |

Guayaquil, Ecuador |

Global Training Schedule, 2017 Q1/Q2

Listed are the instructor-led training courses scheduled through Q2 2017. Classes are subject to a minimum requirement of 12 students. Approximately 30 days prior to the class start date, registered students will receive an email confirming the class is being conducted along with logistical information. You should not make travel arrangements to attend the class until after you have received a confirmation email.

Additional classes can be added throughout the year. It is recommended that you periodically go to the site to check on any that may have been added, revised or removed.

|

Region |

Start Date |

Course Description |

Location |

|

APO |

2/14/2017 |

2 Day Product Update |

Brisbane, Australia |

|

APO |

3/13/2017 |

1 Week Container Technician Certificate |

Mumbai, India |

|

APO |

3/20/2017 |

2 Day Product Update |

Mumbai, India |

|

APO |

5/4/2017 |

2 Day Product Update |

Christchurch, NZ |

|

APO |

5/22/2017 |

1 Week Container Technician Certificate |

Qingdao China |

|

APO |

6/12/2017 |

1 Week Container Technician Certificate |

Chennai , India |

|

APO |

6/19/2017 |

2 Day Product Update |

Chennai , India |

|

EMEA |

2/15/2017 |

2 Day Product Update |

Dammam, Saudi Arabia |

|

EMEA |

3/1/2017 |

2 Day Product Update |

Istanbul, Turkey |

|

EMEA |

3/7/2017 |

2 Day Product Update |

Dublin , Ireland |

|

EMEA |

3/21/2017 |

2 Day Product Update |

Hamburg, Germany |

|

EMEA |

4/11/2017 |

2 Day Product Update |

Alexandria/Port Said |

|

EMEA |

4/11/2017 |

2 Day Product Update |

Aarhus, Denmark |

|

EMEA |

5/9/2017 |

2 Day Product Update |

Rotterdam, The Netherlands |

|

EMEA |

5/9/2017 |

2 Day Product Update |

Felixstowe, U.K |

|

EMEA |

6/14/2017 |

2 Day Product Update |

Tema, Ghana |

|

EMEA |

6/16/2017 |

2 Day Gen Set |

Tema, Ghana |

|

LAO |

1/16/2017 |

2 Day Gen Set |

Mexico City, Mexico |

|

LAO |

3/1/2017 |

2 Day Product Update |

Uruguay |

|

LAO |

3/6/2017 |

1 Week Container Technician Certificate |

Veracruz, Mexico |

|

LAO |

4/1/2017 |

1 Week Container Technician Certificate |

Chile |

|

LAO |

5/1/2017 |

2 Day Gen Set |

Ecuador |

|

LAO |

6/1/2017 |

1 Week Container Technician Certificate |

Fortaleza |

|

LAO |

6/12/2017 |

1 Week Container Technician Certificate |

Puerto Cortez, Honduras |

|

NAO |

3/20/2017 |

1 Week Container Technician Certificate |

Savannah, GA |

|

NAO |

5/1/2017 |

1 Week Container Technician Certificate |

Houston, TX |

|

NAO |

5/1/2017 |

1 Week Container Technician Certificate |

Oakland, CA |

|

NAO |

5/1/2017 |

1 Week Container Technician Certificate |

Chicago, IL |

|

NAO |

5/1/2017 |

2 Day Gen Set |

Oakland, CA |

|

NAO |

5/8/2017 |

1 Week Container Technician Certificate |

Miami, FL |

|

NAO |

6/1/2017 |

1 Week Container Technician Certificate |

Long Beach, CA |

|

NAO |

6/1/2017 |

2 Day Gen Set |

Long Beach, CA |

Listed are the software release versions for operating and working with Carrier Transicold units. Prior to upgrading software on units, you should seek agreement from the equipment owners.

Recip (ML2i / 5159, ML3, 5165), Scroll (ML2i, 5360 /ML3, 5366)

Reciprocating Unit (ML2) – 1207

Controlled Atmosphere – 3115

DataLINE 2.2 (Windows 8 compatible), DataBANK 0513.

Menu – 0116, Software cards with revision greater than 5159 or 5361 must have menu 0116 or an error could occur.

After completing a software upgrade, verify the user selections (i.e. defrost, set point, etc.).

TechLINE is a publication of Carrier Transicold.

Editor / Contributor: Perry Hoover

Contributors: Oh Boon San, Barry Hofsdal, David Whyte, Nadir Guenane

Thanks to all who supported this release.