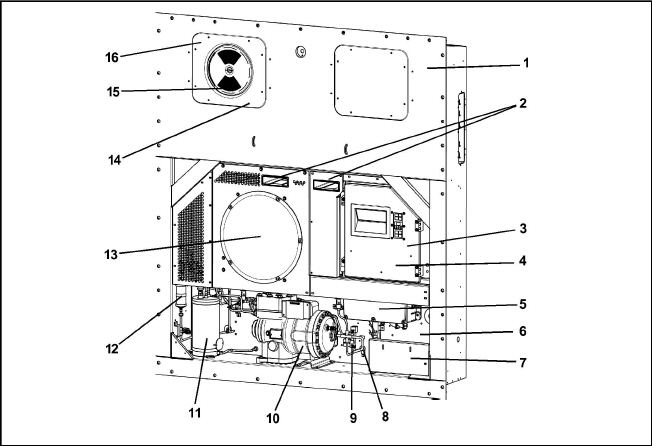

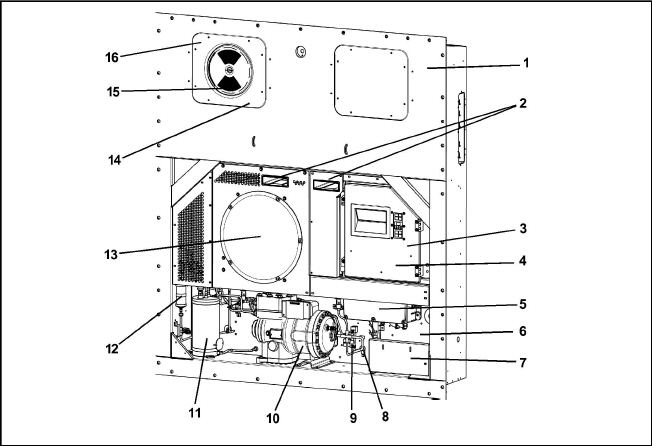

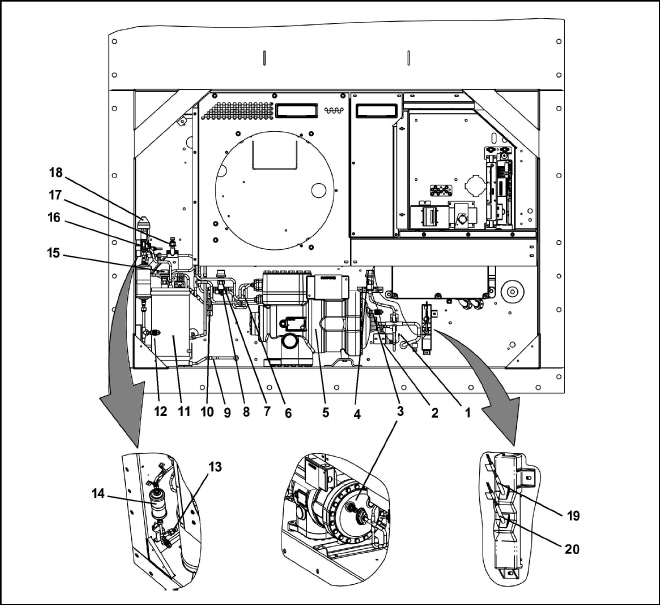

3.1.1Refrigeration Unit - Front Section

The refrigeration unit is designed so that the majority of components are accessible from the front (see Figure 3.1)

The function of the upper fresh air makeup vent is to provide ventilation for commodities that require fresh air circulation. The venting system / vent position sensor (VPS) is located in the upper left access panel.

Figure 3.1 Refrigeration Unit - Front Section

4.Interrogator Connector (Front right)

5.Variable Frequency Drive (VFD)

6.Unit Serial Number, Model Number and Parts Identification Number (PID) Plate

7.Power Cables & Plug (Location)

8.Ambient Temperature Sensor (AMBS)

9.Unloader Solenoid Valve (USV)

14.TIR (Transports Internationaux Routiers) Sealing Provisions - Typical All Panels

15.Upper Fresh Air Makeup Vent panel

16.Access Panel (Evap. Fan #2)

- - - - -

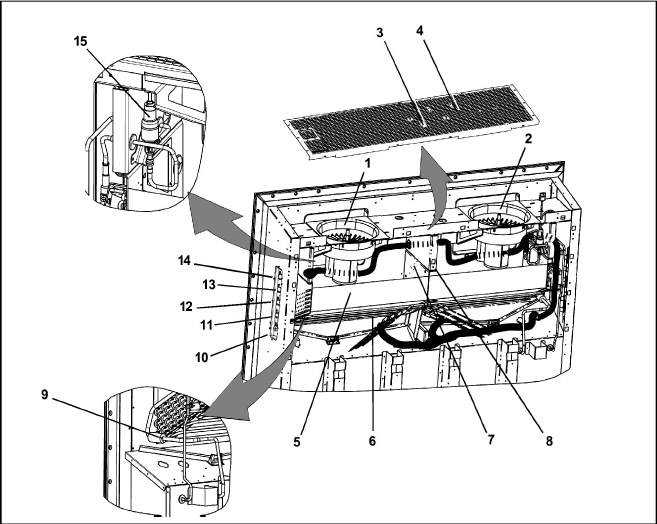

The two evaporator fans circulate air through the container by pulling air in from the top of the unit, directing the air through the evaporator coil where it is cooled or heated, and then discharging the conditioned air at the bottom of the unit.

Most evaporator components are accessible by removing the upper rear panel (as shown in Figure 3.2) or by removing the evaporator fan access panels (see Figure 3.1).

1.Evaporator Fan Motor #1 (EM1)

2.Evaporator Fan Motor #2 (EM2)

3.Return Recorder

Sensor (RRS)

Return Temperature Sensor (RTS)

6.Evaporator Coil Heaters (Underside of Coil)

7.Heater Termination Thermostat (HTT)

8.Defrost Temperature Sensor (DTS)

9.Evaporator Temperature Sensor (ETS)

10.Interrogator Connector (Rear) (ICR)

15.Electronic Expansion Valve (EEV)

- - - - -

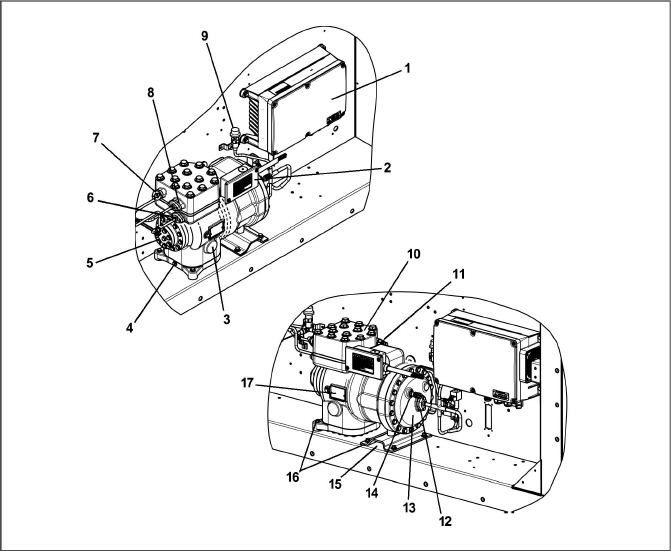

Figure 3.3 Compressor Section (1 of 2)

1.Ambient Temperature Sensor (AMBS)

2.Unloader Solenoid Valve (USV)

4.Low Side Pressure Relief Valve (PRV)

6.Compressor Discharge Temperature Sensor (CPDS)

7.High Side Pressure Relief Valve (PRV)

10.Gas Cooler Temperature Sensor (GCTS)

13.Discharge Pressure Transducer (DPT)

15.Flash Tank Pressure Relief Valve (PRV)

16.Economizer Solenoid Valve (ESV)

17.Flash Tank Pressure Transducer (FPT)

18.High Pressure Expansion Valve (HPXV)

19.Supply Recorder Sensor (SRS)

20.Supply Temperature Sensor (STS)

- - - - -

Figure 3.4 Compressor Section (2 of 2)

1.Variable Frequency Drive (VFD)

3.Compressor Moisture Indicator/Sight Glass (Service Only)

6.First Stage Discharge Port / Flange

7.Second Stage Suction Port / Flange

8.Second Stage Discharge Port / Flange

9.Low Side Pressure Relief Valve (PRV)

11.Suction Pressure Transducer (SPT)

16.Compressor Mounting Bolts (6)

17.Compressor Serial/Model No. Plate

- - - - -

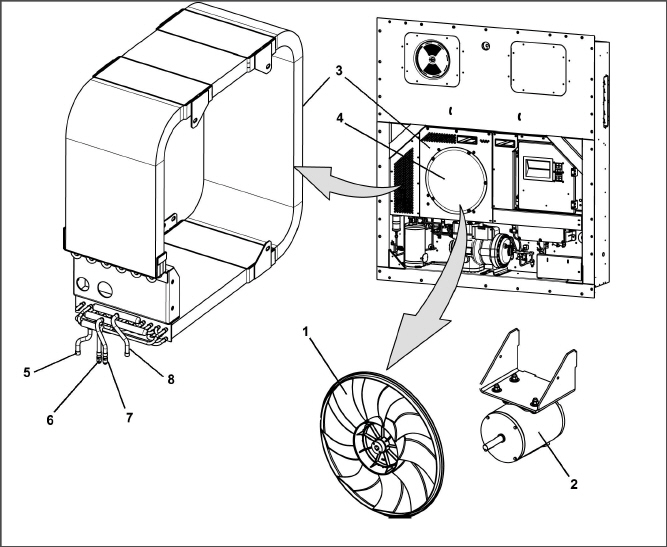

The gas cooler / intercooler coil acts as a heat exchanger in which compressed refrigerant gas from the compressor is lowered in temperature as it circulates through the coil tubes. The gas cooler / intercooler fan pulls external, ambient air through all four sides of the coil, heat transfer from the refrigerant is transferred to the air, and then the warm air is discharged horizontally through the front of the fan grille.

Figure 3.5 Gas Cooler / Intercooler

- - - - -

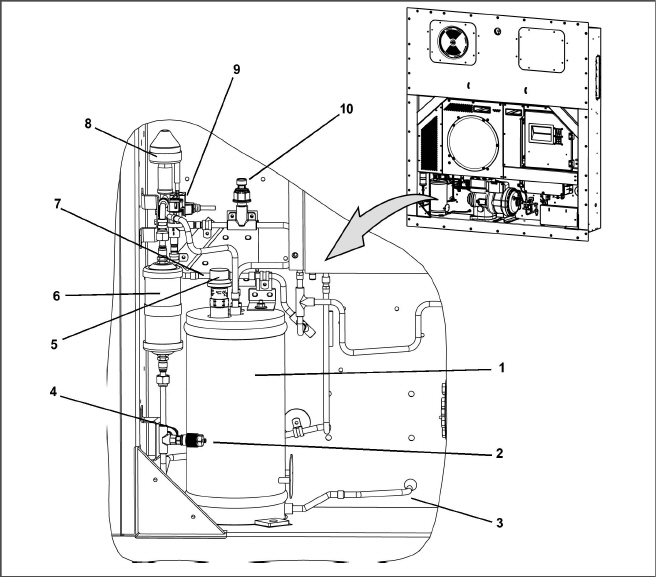

4.Discharge Pressure Transducer (DPT)

5.Flash Tank Pressure Relief Valve (FTPRV)

8.High Pressure Expansion Valve (HPXV)

9.Economizer Solenoid Valve (ESV)

10.Flash Tank Pressure Transducer (FPT)

- - - - -

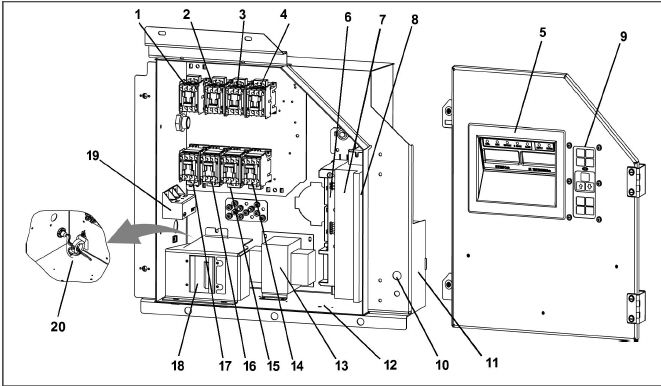

Figure 3.7 Control Box Section

6.Communications Interface Module

7.Controller/DataCORDER Module (Controller)

8.Variable Frequency Interface Module (VIM)

11.Controller Battery Pack (Standard Location)

12.Interrogator Connector (Box Location)

14.High Speed Evap. Fan Contactor - EF

15.Low Speed Evap. Fan Contactor - ES

16.High Speed Gas Cooler Fan Contactor - GF

17.Low Speed Gas Cooler Fan Contactor - GS

- - - - -

3.1.8Communications Interface Module

The optional communications interface module (Figure 3.7 #6) is a slave module that allows communication with a master central monitoring station. The module will respond to communication and return information over the main power line. Refer to the master central monitoring station technical manual for additional information.

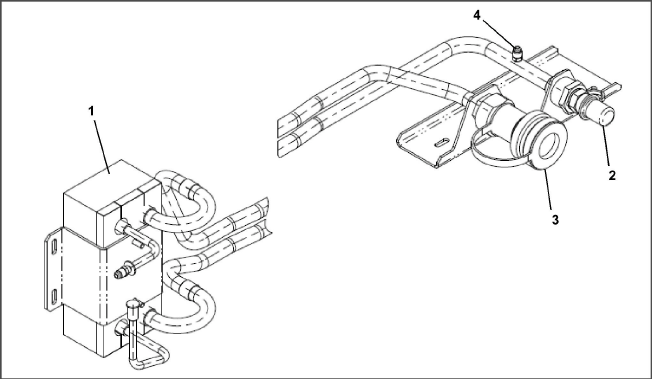

3.1.9Water-Cooled Condenser Section

The water-cooled condenser section (Figure 3.8) consists of a water-cooled condenser, water couplings, and a water pressure switch.

Figure 3.8 Water-Cooled Condenser

3.Self Draining Coupling (Water Out)

- - - - -

Compressor / Motor Assembly |

Model Number |

79-04023-00 |

Weight (With Oil) |

159 kg (350 lb) |

|

Approved Oil |

Carrier P/N 46-00025-06 |

|

Oil Charge |

2000 ml (67 ounces) |

|

|

Oil Sight Glass (Service Compressor Only) |

The oil level range, while the unit operating, should be between 1/4 and 3/4 level of the sight glass. |

Electronic Expansion Valve Superheat (Evaporator) |

Variable |

|

High Pressure Expansion Valve (HPXV) |

Variable |

|

Heater Termination Thermostat (HTT) |

Opens |

54°(+/- 3)C = 130°(+/- 5)F |

Closes |

38°(+/- 4)C = 100°(+/- 7)F |

|

High Pressure Switch (HPS) |

Cut-Out |

138 (+7/-11) bar = 2000 (+100/-156) psig |

Cut-In |

99 (+/- 10) bar = 1430 (+/- 140) psig |

|

Charge according to nameplate specifications to ensure optimal unit performance. |

||

Refrigerant Charge - R-744 |

Unit Configuration |

Charge Requirements |

Purity to be 99.8 pure CO2 |

Refer to nameplate |

|

Pressure Relief Valves Set Pressure |

Opens, Low Side |

89.6 bar = 1300 psig |

Opens, Flash Tank |

108.2 bar = 1569 psig |

|

Opens, High Side |

150.9 bar = 2189 psig |

|

Unit Weight |

Refer to unit model number plate. |

|

Water Pressure Switch (WP) |

Cut-In |

0.5 + 0.2 kg/cm3 (7 + 3 psig) |

Cut-Out |

1.6 + 0.4 kg/cm3 (22 + 5 psig) |

|

Pressure Relief Valves |

Low Side PRV |

65-71 Ft. Lbs. |

Flash Tank PRV |

22-24 Ft. Lbs. |

|

High Side PRV |

38-42 Ft. Lbs. |

|

Pressure Transducers |

Suction Pressure Transducer, SPT |

19-21 Ft. Lbs. |

Flash Tank Pressure Transducer, FTPT |

7-8 Ft. Lbs. |

|

Discharge Pressure Transducer, DPT |

7-8 Ft. Lbs. |

|

Service Fittings |

Suction Service Fitting |

19-21 Ft. Lbs. |

Discharge Service Fitting |

7-8 Ft. Lbs. |

|

Pressure Switch |

High Pressure Switch |

13-14 Ft. lbs. |

Bolts |

Compressor Flange Bolts |

26-28 Ft. Lbs. |

Circuit Breaker |

CB-1 |

25 amps |

|

Compressor Motor |

Full Load Amps (FLA) |

13 amps @ 460 VAC |

|

Gas Cooler Fan Motor |

|

380 VAC, Three Phase, 50 Hz +/- 2.5% Hz |

460 VAC, Three Phase, 60 Hz +/- 2.5% Hz |

Full Load Amps, High Speed |

1.10 amps |

1.20 amps |

|

Full Load Amps, Low Speed |

0.68 amps |

0.69 amps |

|

Horsepower, High Speed |

0.35 hp |

0.60 hp |

|

Horsepower, Low Speed |

0.04 hp |

0.06 hp |

|

RPM, High Speed |

1425 rpm |

1725 rpm |

|

RPM, Low Speed |

720 rpm |

850 rpm |

|

Voltage and Frequency |

360 - 460 VAC |

400 - 506 VAC |

|

Bearing Lubrication |

Factory lubricated, additional grease not required. |

||

Rotation |

CCW when viewed from shaft end. |

||

Evaporator Coil Heaters |

Number of Heaters |

6 |

|

Rating |

750 watts +/- 5% each @ 230 VAC |

||

Resistance (cold) |

72 ohms +/- 5% @ 20°C (68°F) |

||

Type |

Sheath |

||

Evaporator Fan Motors |

|

380 VAC/3 PH/50 Hz |

460 VAC/3 PH/60 Hz |

Full Load

Amps |

1.07 |

0.9 |

|

Full Load

Amps |

0.47 |

0.47 |

|

Nominal Horsepower |

0.36 |

0.63 |

|

Nominal Horsepower |

0.05 |

0.08 |

|

Rotations

Per Minute |

2850 rpm |

3450 rpm |

|

Rotations

Per Minute |

1425 rpm |

1725 rpm |

|

Voltage and Frequency |

360 - 460 VAC +/- 2.5% |

400 - 506 VAC +/- 2.5% |

|

Bearing Lubrication |

Factory lubricated, additional grease not required |

||

Rotation |

CW when viewed from shaft end |

||

Fuses |

Control Circuit |

7.5 amps (F3A,F3B) |

|

Controller / DataCORDER |

5 amps (F1 & F2) |

||

Vent Position Sensor (VPS) |

Electrical Output |

0.5 VDC to 4.5 VDC over 90 degree range |

|

Supply Voltage |

5 VDC +/- 10% |

||

Supply Current |

5 mA (typical) |

||

Solenoid Valve Coils (ESV/USV) 24 VAC |

Nominal Resistance @ 20 C°(68°F) |

12.4 ohms +/- 5% |

|

Maximum Current Draw |

0.7 amps |

||

EEV Nominal Resistance |

Coil Feed to Coil Feed |

100 ohms |

|

Variable Frequency Drive (VFD) |

460 Volts |

Variable Frequency |

|

Humidity Sensor |

Orange wire |

Power |

|

Red wire |

Output |

||

Brown wire |

Ground |

||

Input voltage |

5 VDC |

||

Output voltage |

0 to 3.3 VDC |

||

Output voltage readings verses relative humidity (RH) percentage: |

|||

30% |

0.99 V |

||

50% |

1.65 V |

||

70% |

2.31 V |

||

90% |

2.97 V |

||

3.5Safety and Protective Devices

Unit components are protected from damage by safety and protective devices listed in Table 3–1. These devices monitor the unit operating conditions and open a set of electrical contacts when an unsafe condition occurs.

Open safety switch contacts on either or both of devices IP-CP or HPS will shut down the compressor.

Open safety switch contacts on device IP-CM will shut down the Gas Cooler fan motor.

The entire refrigeration unit will shut down if one of the following safety devices open: (a) circuit breaker(s); (b) fuse (F3A/F3B, 7.5A); or (c) evaporator fan motor internal protector(s) - (IP).

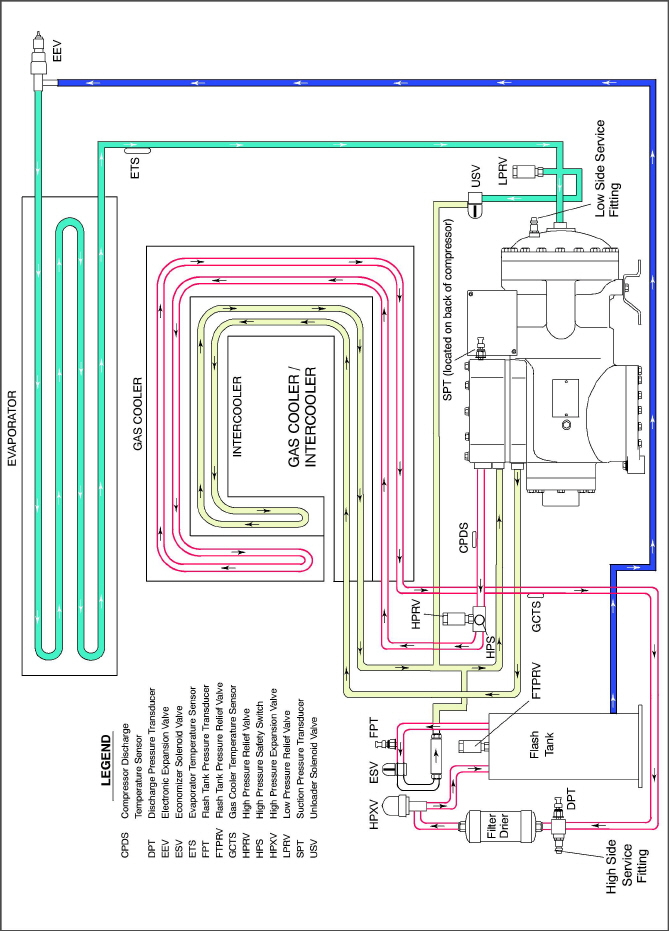

The NaturaLINE unit operates as a vapor compression refrigeration system using R-744 (CO2) as the refrigerant. The main components of the system are a Reciprocating Compressor, Gas Cooler/Intercooler, High Pressure Electronic Expansion Valve (HPXV), Flash Tank, Electronic Expansion Valve (EEV), Economized Solenoid Valve (ESV), Unloader Solenoid Valve (USV) and the Evaporator.

The refrigeration system operates in one of three modes; Standard, Unloaded, or Economized. At system start up, and during periods of low refrigeration load, the unit will operate in Unloaded Mode. This allows the microprocessor to place the system in operation at reduced capacity in order to measure the actual load. If the microprocessor determines that further capacity is required, such as periods of high load or pull down, the system will transition to Economized Mode. Standard Mode is used to maintain temperature during stable load conditions.

At the compressor, the CO2 refrigerant is drawn in at the suction port and compressed into a higher pressure, higher temperature gas. The compressed gas exits the first stage of the compressor, enters the intercooler, then returns back to the compressor at the second stage suction port, where the gas is compressed to a higher pressure and higher temperature. The compressed gas then exits the compressor at the discharge port and flows through the gas cooler. Discharge temperature of the refrigerant is continuously monitored by the compressor discharge temperature sensor (CPDS).

As refrigerant travels through the tubes in the gas cooler, ambient air flowing across the coil fins and tubes removes heat from the refrigerant gas. As heat from the refrigerant is transferred to the ambient air, the refrigerant gas cools and then passes through the filter drier. The filter drier ensures that the refrigerant is clean and dry.

The flow of refrigerant from the filter drier to the flash tank is regulated by the HPXV. The HPXV is controlled by the operating software for optimal performance and efficiency. As the microprocessor receives temperature and pressure data, the HPXV stepper motor will open or close in order to control and maintain maximum system efficiency. As refrigerant flows through the variable orifice of the HPXV, the reduced pressure causes the refrigerant to flash (flash gas) while entering the flash tank. In the flash tank, vapor and liquid are separated.

The liquid refrigerant from the flash tank continues through the liquid line to the EEV. The EEV is used to control the superheat of the refrigerant leaving the evaporator. As the microprocessor receives suction pressure and temperature data, the microprocessor transmits electronic pulses to the EEV stepper motor which opens or closes the variable valve orifice in order to control and maintain proper superheat. Superheat is controlled to ensure that liquid refrigerant never enters the compressor.

The liquid refrigerant flows through the evaporator, absorbing heat from the return air as the return air flows across the fins and tubes of the evaporator coil. As the liquid refrigerant in the evaporator coil absorbs heat, the refrigerant vaporizes, and the vapor flows through the suction port back to the compressor.

3.6.2First Stage Discharge Port & Suction Port

The higher pressure, higher temperature refrigerant that is discharged from the first stage discharge port flows directly to the intercooler section of the gas cooler/intercooler. As the refrigerant travels through the tubes in the intercooler, ambient air flowing across the coil fins and tubes removes heat, cooling but not condensing the gas. The refrigerant leaving the intercooler flows to three locations: the check valve (where it is stopped), the Unloader Solenoid Valve (USV) (which is normally closed in Standard and Economized Mode), and to the mid-stage suction port where refrigerant returns to the compressor.

During system start up and periods of low cooling load, the unit will operate in Unloaded Mode to conserve energy. In Unloaded Mode the normally closed USV opens. While in Unloaded Mode a portion of the refrigerant leaving the intercooler is redirected to the suction port, back to the compressor. The remaining portion of the refrigerant leaving the intercooler continues to the second stage suction port. To further reduce cooling, the Variable Frequency Drive (VFD) may reduce compressor speed.

In Economized Mode, the main refrigeration system operates the same as in Standard Mode, except the microprocessor energizes (opens) the Economizer Solenoid Valve (ESV). When the ESV is open, frozen and pull down capacity of the unit is increased by allowing refrigerant vapor to flow from the flash tank through the check valve, and to the mid-stage suction port where the refrigerant returns to the compressor. During Economized Mode the USV will remained closed.

3.6.5Electronic Expansion Valve (EEV)

The microprocessor controls the superheat of refrigerant leaving the evaporator by opening and closing the variable orifice in the EEV. The microprocessor transmits electronic pulses to the EEV stepper motor, which opens or closes the valve orifice to maintain superheat. EEV control is based on inputs from the suction pressure transducer (SPT) and the evaporator temperature sensor (ETS).

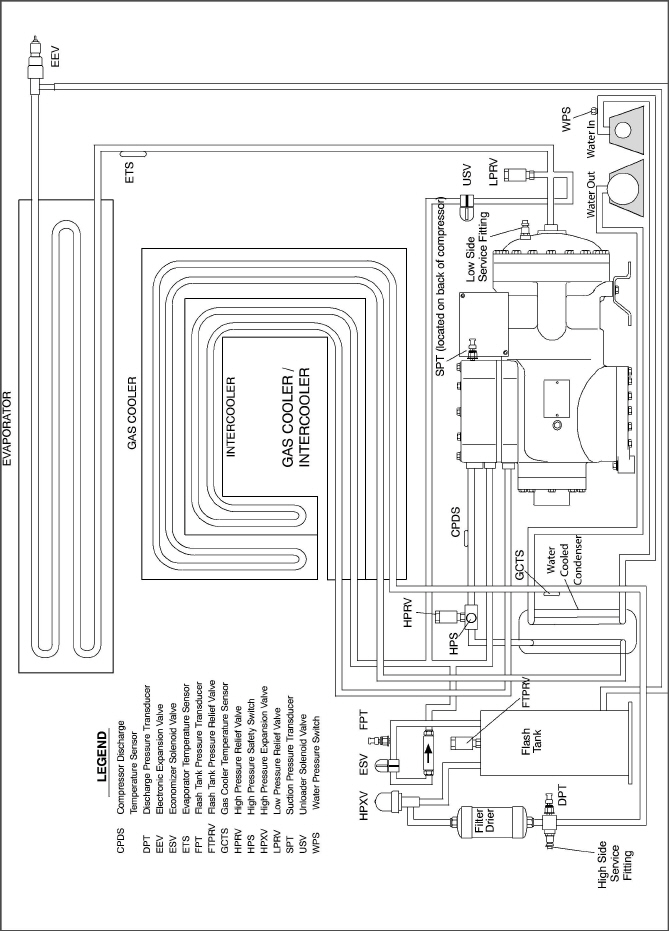

Figure 3.9 Refrigeration Circuit Schematic (Air-Cooled)

Figure 3.10 Refrigeration Circuit Schematic (Water-Cooled)